Nhanganyaya yeVia-in-pad:

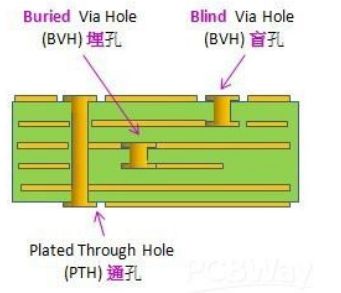

Zvinozivikanwa chaizvo kuti Vias (kuburikidza) inogona kukamurwa kuita yakavezwa kuburikidza negomba, bofu Vias hove uye yakaviga gomba, ine mabasa akasiyana.

Nekuvandudzwa kwezvigadzirwa zvemagetsi, vias tite basa rakakosha mukuwirirana kwakasarudzika pamabhodhi edunhu redunhu rakadhindwa. Via-in-Pad inoshandiswa zvakanyanya mune diki PCB uye BGA (bhora grid array). Nekusimudzira kusiri kusingagonekwe kweGreatity density, BGA (bhora grid array) uye smd chip miniaturization, kushandiswa kwe-mu-pad tekinoroji kuri kuwedzera uye zvakanyanya kukosha.

Vias mumapapaki ane zvakawanda zvakanakira pamusoro pemapofu uye akavigwa vias:

. Yakakodzera pitch yakanaka bga.

. Izvo zviri nyore kugadzira yakakwira density PCB uye chengetedza wiring nzvimbo.

. Zviri nani zvekutonga.

. Anti-low inductance uye imwe yakakwira-kumhanya dhizaini.

. Inopa nzvimbo yekubata kumeso.

. Deredza PCB nzvimbo uye kumwezve kugadzirisa wiring.

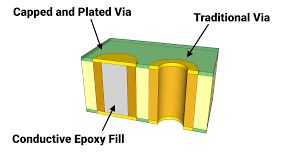

Nekuda kwezvakanaka izvi, kuburikidza-mune-pad inowanzoshandiswa zvakanyanya muPCBs diki, kunyanya muPCB zvigadzirwa kuti kupisa kuchinjisa nekumhanya kwakakwira kunodiwa nelimed bga pitch. Kunyangwe mapofu uye akavigwa vias kubatsira kuwedzera density uye chengetedza nzvimbo paPCBS, VISI MUCS ichiri sarudzo yakanakisa yeApper

Nechivanhu akavimbika Uye zvakare, izvi zvinogona kupa mamwe wa waya yekubatanidza yeBGA zvigadzirwa.

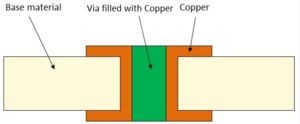

Kune zvinhu zvakasiyana siyana zvinozadza gomba mundiro, Silver pasireti uye marara pasita anoshandiswa kune zvekuita zvinhu, uye resin inowanzoshandiswa kune zvisiri zvekuita zvinhu