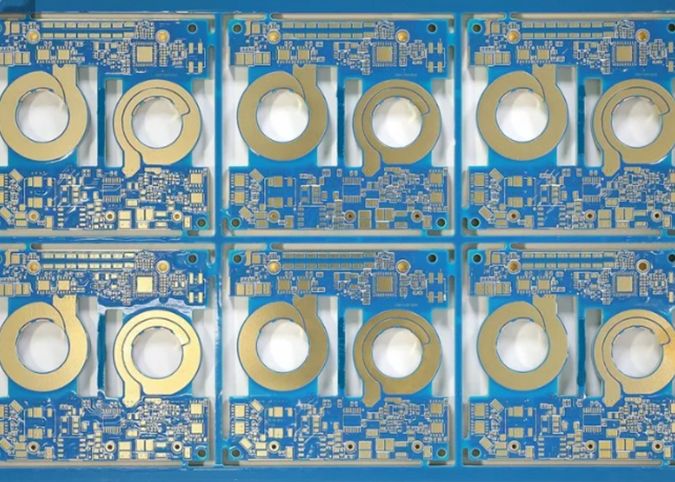

Zvishandiso zvedunhu zvinotsamira pane emhando yepamusoro conductor uye dielectric zvinhu kuti zvibatanidze zvinhu zvemazuva ano zvakaoma kune mumwe nemumwe kuti zviite zvakakwana. Nekudaro, semakondakita, aya PCB copper conductor, angave DC kana mm Wave PCB mabhodhi, anoda anti-kuchembera uye oxidation dziviriro. Kudzivirirwa uku kunogona kuwanikwa nenzira ye electrolysis uye kunyudza coatings. Ivo vanowanzopa akasiyana madhigirii ekugonesa weld, zvekuti kunyangwe iine zvikamu zvidiki-diki, micro-surface gomo (SMT), nezvimwewo, nzvimbo yakakwana yeweld inogona kuumbwa. Kune akasiyana machira uye epamusoro marapirwo anogona kushandiswa paPCB copper conductors muindasitiri iyi. Kunzwisisa hunhu uye mari inodiwa yekupfekedza yega yega uye kurapwa kwepamusoro kunotibatsira kuita sarudzo yakakodzera kuti tiwane kuita kwepamusoro uye hupenyu hurefu hwesevhisi yePCB mabhodhi.

Kusarudzwa kwekupedzisira kwePCB haisi nzira yakapusa inoda kufunga nezvechinangwa chePCB uye mamiriro ekushanda. Iyo yazvino maitiro akananga kuzere kwakazara, yakaderera-pitch, yakakwira-kumhanya PCB maseketi uye madiki, akatetepa, akakwira-frequency PCBS anounza matambudziko kune vazhinji vanogadzira PCB. Maseketi ePCB anogadzirwa kuburikidza nemalaminates emhando dzakasiyana dzemhangura foil huremu uye ukobvu hunopihwa kune vanogadzira PCB nevagadziri vezvinhu, senge Rogers, avo vanozogadzira aya laminate mumhando dzakasiyana dzePCBS kuti ishandiswe mumagetsi. Pasina imwe nzira yekudzivirira kwepamusoro, maconductor ari padunhu anozoisa oxidize panguva yekuchengetedza. Conductor surface treatment inoshanda sechipinganidzo chinoparadzanisa conductor kubva kune zvakatipoteredza. Iyo haingodziviriri PCB conductor kubva kune oxidation, asi inopawo chinongedzo chewelding maseketi uye zvikamu, zvinosanganisira lead bonding yemaseketi akabatanidzwa (ics).

Sarudza yakakodzera PCB pamusoro

Yakakodzera pamusoro kurapwa kunofanira kubatsira kusangana nePCB redunhu application pamwe nekugadzira maitiro. Mutengo unosiyana nekuda kwemitengo yakasiyana yezvinhu, maitiro akasiyana uye marudzi ekupedzisa anodiwa. Mamwe marapirwo epamusoro anobvumira kuvimbika kwepamusoro uye kuparadzaniswa kwepamusoro kwemaseketi akaomeswa, nepo mamwe anogona kugadzira mabhiriji asina kufanira pakati pemakondakita. Mamwe marapirwo epamusoro anosangana nezvido zvemauto uye zvemuchadenga, senge tembiricha, kuvhunduka uye kudedera, nepo mamwe asingavimbisi kuvimbika kwepamusoro kunodiwa kune izvi zvikumbiro. Pazasi pane mamwe ePCB epamusoro marapirwo anogona kushandiswa mumaseketi kubva kuDC maseketi kusvika mamirimita-wave mabhendi uye high speed digital (HSD) maseketi:

●ENIG

●ENEPIG

●HASL

●Kunyudza Sirivha

●Kunyudza Tin

●LF HASL

● OSP

● Electrolytic hard gold

●Electrolytically bonded goridhe nyoro

1.ENIG

ENIG, inozivikanwawo sekemikari nickel-goridhe process, inoshandiswa zvakanyanya mukurapa kwepamusoro kwePCB board conductors. Iyi inzira yakapfava yakachipa inoumba dhanda regoridhe rinogoneka pamusoro penickel layer pamusoro pecondukita, zvichikonzera nzvimbo yakati sandara ine kugona kwakanaka kweweld kunyangwe pamaseketi akazara. Kunyange zvazvo ENIG maitiro anovimbisa kutendeseka kwe-buri-hole electroplating (PTH), inowedzerawo kurasikirwa kwekondukita pahuwandu hwepamusoro. Iyi nzira ine hupenyu hurefu hwekuchengetedza, maererano nemitemo yeRoHS, kubva kumugadziri wedunhu, kusvika kune chikamu chegungano, pamwe chete nechigadzirwa chekupedzisira, inogona kupa kuchengetedzwa kwenguva refu kwePCB conductors, saka vazhinji vanogadzira PCB vanosarudza common surface treatment.

2.ENEPIG

ENEPIG kukwidziridzwa kweiyo ENIG maitiro nekuwedzera yakaonda palladium layer pakati pekemikari nickel layer uye yegoridhe plating layer. Iyo palladium layer inodzivirira nickel layer (iyo inodzivirira conductor yemhangura), nepo goridhe layer inodzivirira zvese palladium uye nickel. Uku kurapwa kwepamusoro kwakanakira kubatanidza zvishandiso kuPCB inotungamira uye inogona kubata akawanda ekudzoreredza maitiro. Kufanana neENIG, ENEPIG inoenderana neRoHS.

3.Kunyudza Silver

Kemikari sirivheri sedimentation zvakare isiri-electrolytic kemikari maitiro umo PCB inonyudzwa zvachose mune mhinduro yesirivheri ions kusunga sirivha pamusoro pemhangura. Iyo inokonzeresa yekuvhara inowirirana uye yakafanana kupfuura ENIG, asi inoshaya dziviriro uye kusimba kunopiwa neiyo nickel layer mu ENIG. Kunyangwe iyo nzira yekurapa yepamusoro iri nyore uye inodhura-inoshanda kupfuura ENIG, haina kukodzera kuchengetwa kwenguva refu nevagadziri vedunhu.

4.Kunyudza Tin

Kemikari tin deposition processs inoumba yakatetepa tin yakanamira pane conductor pamusoro kuburikidza neakawanda-nhanho maitiro anosanganisira kuchenesa, micro-etching, acid solution prepreg, kunyudzwa kweisina-electrolytic tin leaching solution, uye kuchenesa kwekupedzisira. Kurapa kweTin kunogona kupa dziviriro yakanaka yemhangura uye maconductor, zvichipa kuderera kwekurasikirwa kwekuita kweHSD maseketi. Sezvineiwo, kemikari yakanyura kemikari haisi imwe yeakarebesa-inogara conductor pamusoro pekurapa nekuda kwemhedzisiro iyo tini ine pamhangura nekufamba kwenguva (kureva, kupararira kwesimbi mune imwe kunoderedza kushanda kwenguva refu kwemudhiraivha wedunhu). Kufanana nekemikari sirivheri, kemikari tini inzira isina mutobvu, inoenderana neRoHs.

5.OSP

Iyo organic welding yekudzivirira firimu (OSP) isiri-simbi inodzivirira iyo inoputirwa nemvura-based solution. Kupedzisa uku zvakare kunoenderana neRoHS. Nekudaro, ichi chepamusoro kurapwa hachina hupenyu hurefu hwepasherufu uye inonyatso shandiswa dunhu risati raiswa uye zvikamu zvakasungirirwa kuPCB. Munguva ichangopfuura, matsva eOSP membranes akaonekwa pamusika, ayo anofungidzirwa kuti anogona kupa kuchengetedzwa kwenguva refu kwevanotungamira.

6.Electrolytic goridhe rakaoma

Kurapwa kwegoridhe rakaomarara inzira ye electrolytic inoenderana neiyo RoHS maitiro, ayo anogona kudzivirira PCB uye conductor yemhangura kubva kune oxidation kwenguva yakareba. Zvisinei, nekuda kwekudhura kwezvinhu, ihwowo humwe hunodhura hwepamusoro hwekuputira. Iyo zvakare ine kushomeka kwemagetsi, kushomeka kwekubatanidza kurapwa kwakapfava kwegoridhe, uye inoenderana neRoHS uye inogona kupa nzvimbo yakanaka yekuti mudziyo ubatanidze kune anotungamira ePCB.