Electroplated hole sealing yakajairika yakadhindwa yedunhu bhodhi kugadzira maitiro anoshandiswa kuzadza uye kuvhara kuburikidza nemakomba (kuburikidza-maburi) kuwedzera magetsi conductivity nekudzivirira. Mune yakadhindwa yedunhu bhodhi yekugadzira maitiro, gomba rekupfuura-negomba ndiyo chiteshi chinoshandiswa kubatanidza matunhu akasiyana. Chinangwa chekuisa chisimbiso che electroplating ndechekuita kuti madziro emukati emukati meburi azere nezvinhu zvinofambisa nekugadzira dhizaini yesimbi kana conductive material deposition mukati meburi, nekudaro kusimudzira conductivity yemagetsi uye kupa chisimbiso chiri nani.

1.the circuit board electroplating sealing process yakaunza mabhenefiti akawanda mukugadzirwa kwechigadzirwa:

a) Kuvandudza kuvimbika kwedunhu: redunhu bhodhi electroplating sealing process inogona kunyatsovhara maburi uye kudzivirira yemagetsi pfupi dunhu pakati pesimbi simbi pane redunhu bhodhi. Izvi zvinobatsira kuvandudza kuvimbika uye kugadzikana kwebhodhi uye kuderedza dambudziko rekuparara kwedunhu uye kukanganisa

b)Kuvandudza mashandiro edunhu: Kuburikidza neiyo electroplating sealing process, zvirinani kutenderera kwedunhu uye conductivity yemagetsi inogona kuwanikwa. Electroplate yekuzadza gomba inogona kupa yakagadzikana uye yakavimbika yedunhu yekubatanidza, kuderedza dambudziko rekurasikirwa kwechiratidzo uye impedance mismatch, uye nekudaro kuvandudza kugona kwedunhu kuita uye kubereka.

c) Kuvandudza welding mhando: circuit board electroplating sealing process inogonawo kuvandudza welding mhando. Iyo yekuisa chisimbiso inogona kugadzira nzvimbo yakati sandara, yakatsetseka mukati megomba, ichipa hwaro huri nani hwewelding. Izvi zvinogona kuvandudza kuvimbika uye kusimba kwewelding uye kuderedza kuitika kwekuremara kwewelding uye kutonhora kwemagetsi matambudziko.

d)Simbisa simba remuchina: Iyo electroplating sealing process inogona kuvandudza simba remakanika uye kusimba kwebhodhi redunhu. Kuzadza maburi kunogona kuwedzera ukobvu uye kusimba kwebhodhi redunhu, kunatsiridza kuramba kwayo pakukotama uye kuzununguka, uye kuderedza njodzi yekukuvadzwa kwemakina uye kuputsika panguva yekushandiswa.

e) Kuungana kuri nyore uye kuisirwa: redunhu bhodhi electroplating sealing process inogona kuita kuti kuungana uye kuisirwa maitiro kuve nyore uye anoshanda. Kuzadza maburi kunopa nzvimbo yakagadzikana uye nzvimbo dzekubatanidza, zvichiita kuti kuiswa kwegungano kuve nyore uye kwakanyanya. Mukuwedzera, electroplated hole sealing inopa kuchengetedzwa kuri nani uye inoderedza kukuvadzwa uye kurasikirwa kwezvikamu panguva yekuisa.

Kazhinji, iyo redunhu bhodhi electroplating sealing process inogona kuvandudza kuvimbika kwedunhu, kuwedzera mashandiro edunhu, kuvandudza welding mhando, kusimbisa simba remakanika, uye kufambisa kuungana nekuiswa. Aya mabhenefiti anogona kuvandudza zvakanyanya kunaka kwechigadzirwa uye kuvimbika, uku achidzikisa njodzi uye mutengo mukugadzira maitiro

2.Kunyange iyo yedunhu bhodhi electroplating sealing process ine zvakawanda zvakanakira, kune zvakare dzimwe njodzi dzinogona kuitika kana zvikanganiso, kusanganisira zvinotevera:

f) Kuwedzera mitengo: Iyo bhodhi yekuisa gomba yekuisa chisimbiso process inoda mamwe maitiro uye zvinhu, senge zvinhu zvekuzadza uye makemikari anoshandiswa muplating process. Izvi zvinogona kuwedzera mutengo wekugadzira uye kuve nemhedzisiro pahupfumi hwese hwechigadzirwa

g) Kuvimbika kwenguva refu: Kunyangwe iyo electroplating sealing process inogona kuvandudza kuvimbika kwebhodhi redunhu, kana iri nguva yekushandiswa kwenguva refu uye shanduko yezvakatipoteredza, iyo yekuzadza zvinhu uye kupfeka kunogona kukanganiswa nezvinhu zvakaita sekuwedzera kwekupisa uye kutonhora. contraction, humidity, corrosion uye zvichingodaro. Izvi zvinogona kutungamira kune yakasununguka yekuzadza zvinhu, kudonha, kana kukuvadzwa kweplating, kuderedza kuvimbika kwebhodhi.

h) 3Process kuoma: Iyo yedunhu bhodhi electroplating sealing process yakanyanya kuoma pane yakajairika maitiro. Inosanganisira kutonga kwematanho akawanda uye maparamendi akadai sekugadzirira gomba, kuzadza kusarudzwa kwezvinhu uye kuvaka, electroplating process control, etc. Izvi zvingada hunyanzvi hwekuita hunyanzvi uye midziyo kuti ive nechokwadi chekugadzirisa uye kugadzikana.

i) Wedzera maitiro: wedzera nzira yekuisa chisimbiso, uye wedzera iyo inovharira firimu kumakomba akati kurei kuti uve nechokwadi chekuisa chisimbiso. Mushure mekuvhara gomba, zvinodikanwa kufoshora mhangura, kukuya, kupurisa uye mamwe matanho kuti ave nechokwadi chekudzikama kwechisimbiso chepamusoro.

j)Kukanganisa kwezvakatipoteredza: Makemikari anoshandiswa mukugadzira chisimbiso che electroplating anogona kuve nekukanganisa zvakatipoteredza. Semuenzaniso, tsvina uye tsvina yemvura inogona kugadzirwa panguva ye electroplating, iyo inoda kurapwa kwakakodzera uye kurapwa. Pamusoro pezvo, panogona kunge paine zvikamu zvinokuvadza zvakatipoteredza mumidziyo yekuzadza iyo inoda kutariswa nemazvo uye kuraswa.

Paunenge uchifunga nezve redunhu bhodhi electroplating sealing process, zvinofanirwa kunyatso funga izvi zvinogona njodzi kana kukanganisa, uye kuyera zvakanakira nezvayakaipira zvinoenderana nezvinodiwa chaizvo uye mamiriro ekushandisa. Paunenge uchiita hurongwa, hwakakodzera hutongi hwemhando uye matanho ekutonga kwezvakatipoteredza zvakakosha kuti uve nechokwadi chemhedzisiro yemaitiro uye kuvimbika kwechigadzirwa.

3.Kugamuchira mitemo

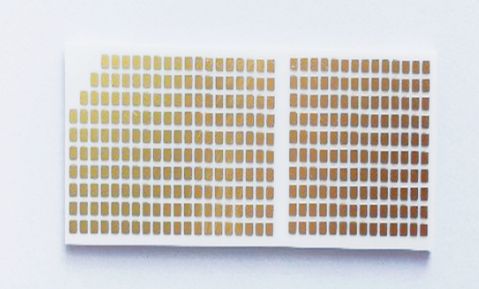

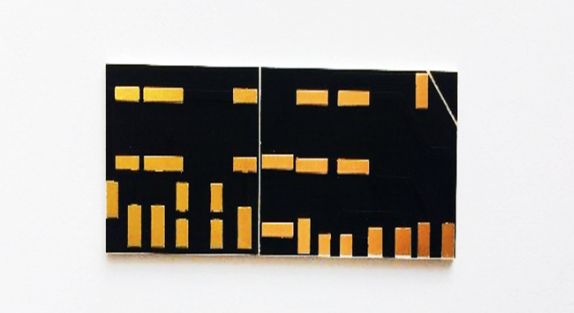

Zvinoenderana nechiyero: IPC-600-J3.3.20: Electroplated mhangura plug microconduction (bofu uye kuvigwa)

Sag uye bulge: Izvo zvinodikanwa zvebulge (bump) uye kushushikana (gomba) rebofu micro-kuburikidza negomba zvichatemerwa nekupa uye kudiwa mapato kuburikidza nekutaurirana, uye hapana chinodiwa chebulge uye kushushikana kweiyo yakabatikana micro. -kuburikidza neburi remhangura. Matsamba chaiwo ekutenga vatengi kana zviyero zvevatengi sehwaro hwekutonga.