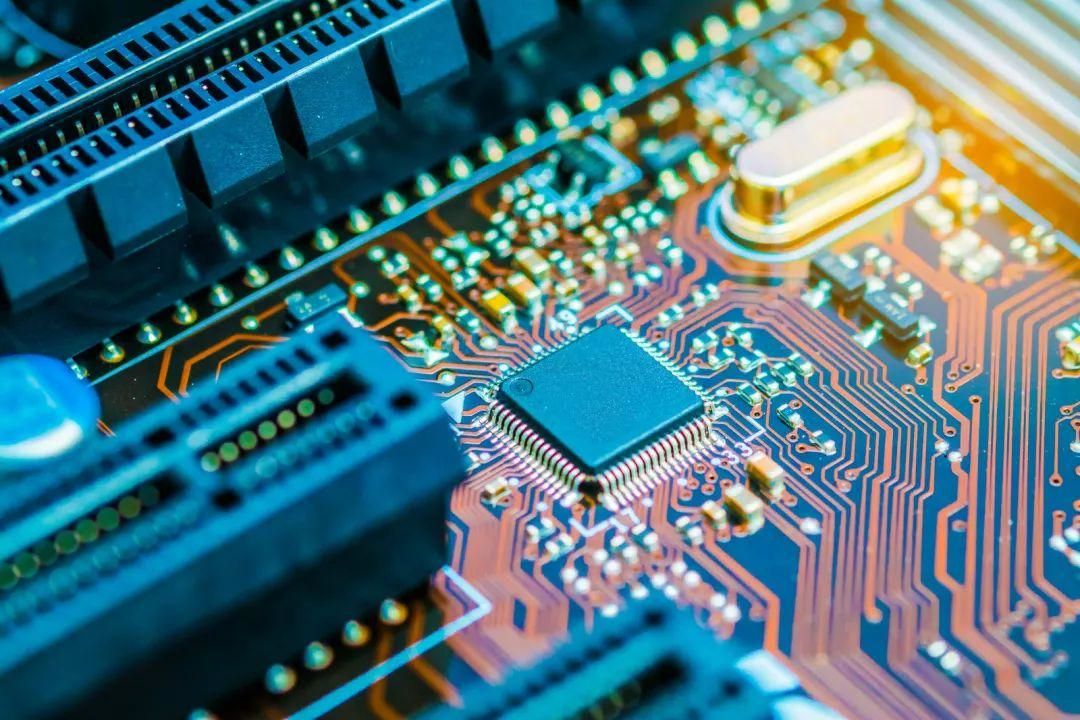

PCB Circumd Board muitiro wekugadzira, kazhinji unosangana neimwe nzira inoremara, yakadai sePCB Circed board waya wire off (inowanzotaurwa kuti kukanda mhangura), kubata mhando yechigadzirwa. Zvikonzero zvakajairika zvePCB Circumd Board Kukanda mhangura ndeyekutevera:

PCB Circuit Board Process Factors Factors

1

2.. Uku kururamisa kuratidzira sekusimba kwepamhepo kana kutaridzika, kudonha waya yemhangura kuchave nekupokana kuri pachena, kana nenzira imwecheteyo yekukanda / kukanganisa Mako. Peel kubva kune yakaipa chikamu cheiyo mhangura kuti uone iyo mhangura foil pamusoro, iwe unogona kuona iyo yakajairwa ruvara rwevhavha yemhangura, hakuzove nekuparadza kwakashata, mhangura foiling simba rakajairika.

3, PCB Circumd Dhizaini haina musoro, ine mativi emhangura foil dhizaini yemutsara mutete, ichakonzerawo mutsara wekutora uye ndarira.

Laminate Process Chikonzero

Mumamiriro ezvinhu akajairwa, chero bedzi iyo inopisa yekudzvanya tembiricha yekushambadzira kupfuura maminitsi anopfuura makumi matatu Nekudaro, mukuita kwekuremedza kuiswa uye kusvibiswa, kana PP kusvibiswa kwemukati kwekuremerwa kwesimba

Laminate Raw Chinyorwa Chinoita

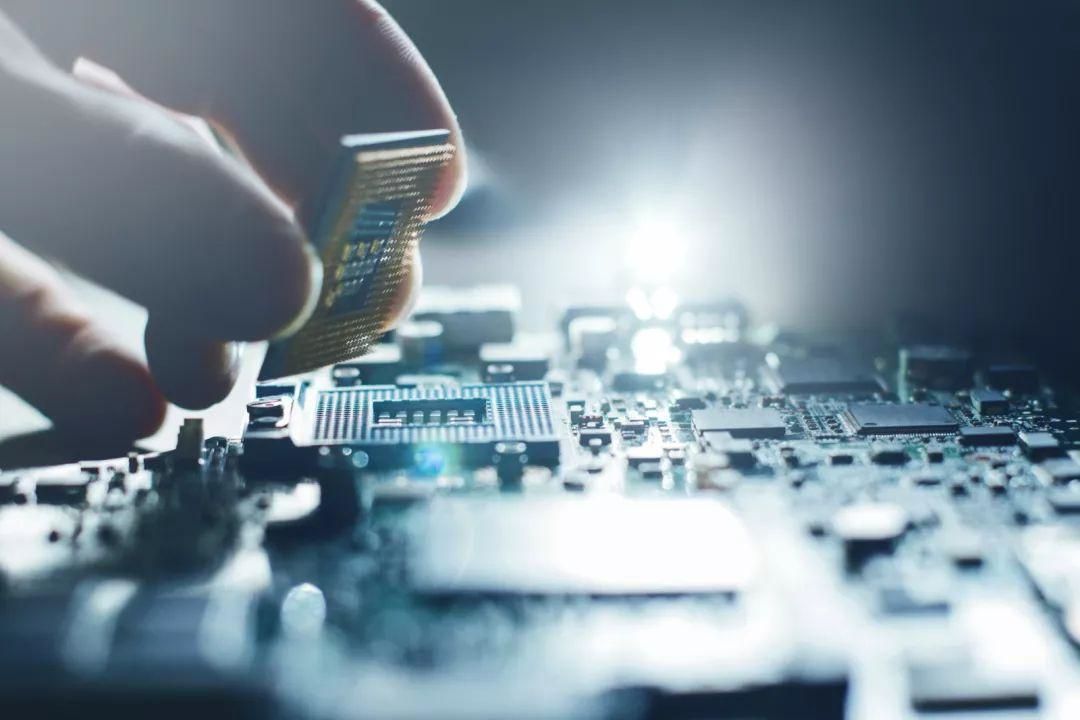

1. Rudzi urwu rwe yakaipa stripping waya yemhangura yemhangura foil foil (iyo, kusangana neiyo substrate) mushure mekusimuka kwesimbe, asi nzvimbo yese yemhangura foil inobereka simba ichava murombo.

2.. Kana kugadzirwa kwekurara uchishandisa mhangura foil uye iyo sisitimu haina kuenderana, zvichikonzera sheet simbi foil proel proel

Mukuwedzera, zvingave zvisina kufanira zvekutengesa mutengi zvinotungamira pakurasikirwa kwePad (kunyanya nemabhodhi makuru emahara, kupisa kupisa, kupisa kwakakwirira, hazvisi nyore kuwa):

● Kudzokorora kutevedzera nzvimbo ichaburitsa pad yekuenda;

● Tembiricha yakanyanya yekutengesa simbi iri nyore kusimuka kubva paki;

● Kumanikidza kwakawanda kunorwiswa nemutengesi wedhiri remusoro pane imwe pad uye yakareba-yakareba nguva yakareba ichavhara pad.