Chikonzero chePCB inodonha solder ndiro

PCB redunhu bhodhi mukugadzira muitiro, kazhinji kusangana nevamwe muitiro kuremara, akadai PCB redunhu bhodhi copper waya kure zvakaipa (inowanzonziwo kukanda mhangura), kukanganisa chigadzirwa unhu. Zvikonzero zvinowanzoitika zvePCB redunhu bhodhi kukanda mhangura ndezvizvi:

PCB redunhu bhodhi process zvinhu

1, copper foil etching yakawandisa, electrolytic foil yemhangura inoshandiswa pamusika inowanzoiswa galvanized single-side (inowanzozivikanwa segrey foil) uye imwe-side yakapfatwa mhangura (inowanzozivikanwa semapepa matsvuku), mhangura yakajairika inowanzopfuura 70um marara. foil yemhangura, foil dzvuku uye 18um pazasi peiyo madota foil yanga isiri batch yemhangura.

2. Kudhumhana kwemunharaunda kunoitika muPCB process, uye waya yemhangura inoparadzaniswa kubva kune substrate nekunze kwemagetsi simba. Ichi chikanganiso chinoratidza kusamira zvakanaka kana kutarisika, waya yemhangura inodonha ichave nekukanganiswa kuri pachena, kana munzira imwechete yekukwenya / kukanganisa chiratidzo. Bvisa chikamu chakashata chewaya yemhangura kuti uone iyo yemhangura foil pamusoro, unogona kuona yakajairika ruvara rwemhangura foil pamusoro, hapazovi nekushata kwekukukurwa kwedivi, kusimba kwemhangura kusvuura kusimba kwakajairika.

3, PCB yedunhu dhizaini haina musoro, ine gobvu yemhangura foil dhizaini yemutsetse wakatetepa zvakare, inokonzeresa yakawandisa mitsara etching nemhangura.

Laminate process chikonzero

Mumamiriro ezvinhu akajairwa, chero bedzi iyo inopisa tembiricha yepamusoro yelaminate inopfuura maminetsi makumi matatu, foil yemhangura uye semi-yakaporeswa sheet inosanganiswa zvachose, saka kudzvanya kazhinji hakuzokanganisa kusungirirwa kwefoiri yemhangura uye substrate mune laminate. Nekudaro, mukugadzirisa laminate stacking uye stacking, kana PP kusvibiswa kana mhangura foil kukuvara kwepamusoro, zvinotungamira kune isina kukwana bonding simba pakati pemhangura foil uye substrate mushure melaminate, zvichikonzera kumira (chete kweplate hombe) kana sporadic copper waya. kurasikirwa, asi simba rekubvisa remhangura foil padyo nemutsetse wekubvisa hazvizove zvisina kujairika.

Laminate mbishi zvinhu chikonzero

1, yakajairika electrolytic foil yemhangura inogadzirwa nemagetsi kana yemhangura-yakaputirwa zvigadzirwa, kana iyo yepamusoro kukosha kweiyo shinda yekugadzira foil isiri yemazuva ese, kana galvanized/mhangura plating, coating dendritic yakaipa, zvichikonzera kuti foil yemhangura pachayo inosvuura simba haina kukwana, iyo foil yakaipa. yakadzvanywa bhodhi yakagadzirwa nePCB plug-in mufekitori yemagetsi, waya yemhangura inodonha nekukanganisa kwekunze. Iyi mhando yakaipa yekubvisa mhangura waya yemhangura foil pamusoro (kureva, kuonana pamusoro neiyo substrate) mushure mekudzungaira kweparutivi, asi pasi rose remhangura foil peeling simba richava murombo.

2. Kusagona kuchinjika kwefoiri yemhangura neresin: mamwe maramina ane zvinhu zvakakosha anoshandiswa ikozvino, senge HTg sheet, nekuda kweakasiyana masisitimu eresin, mushonga wekurapa unoshandiswa unowanzo PN resin, resin molecular chain structure iri nyore, yakaderera crosslinking degree kana. kurapa, kushandisa yakakosha peak copper foil uye match. Kana kugadzirwa kwelaminate uchishandisa foil yemhangura uye resin system isingaenderane, zvichikonzera kuti shizha resimbi foil kusvuura simba harina kukwana, plug-in ichaonekwawo yakashata yemhangura waya.

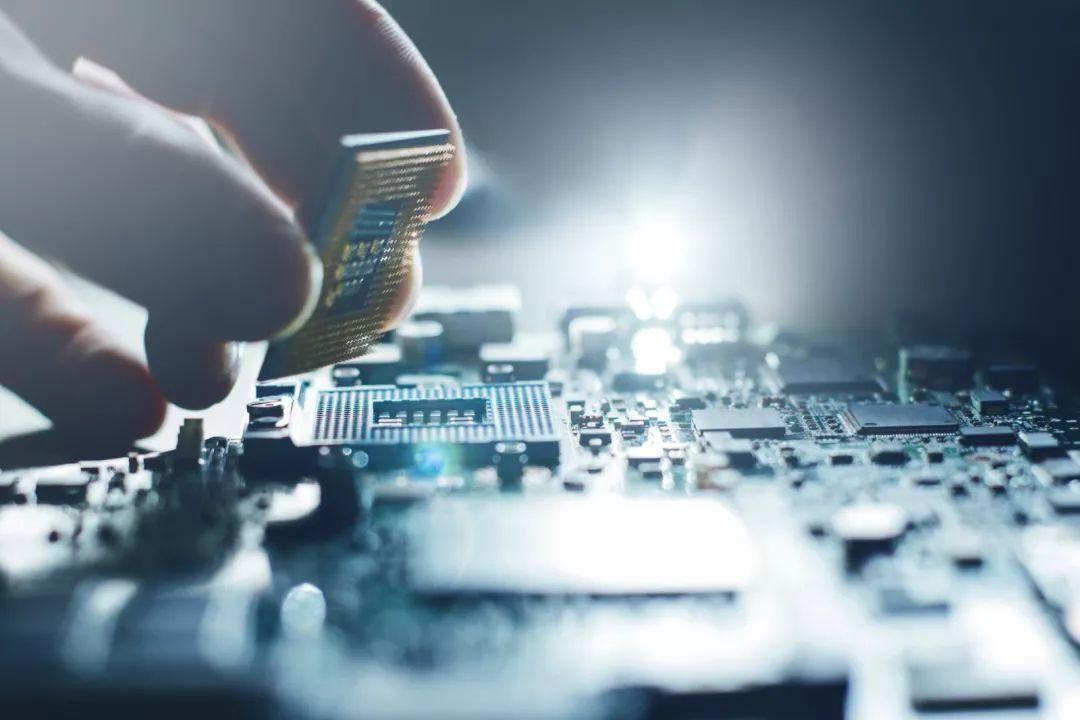

Mukuwedzera, zvingave izvo zvisina kufanira welding mumutengi zvinotungamirira mukurasikirwa kwepadhesi yewelding (kunyanya singles uye kaviri panels, multilayer boards ane nzvimbo yakakura yepasi, kukurumidza kupisa kupisa, kupisa kwekushisa kwakanyanya, hazvisi nyore. kudonha):

Kudzokorodza kuchoserwa nzvimbo kunozochipisa padhi;

Kupisa kwepamusoro kwesimbi yekunyungudutsa kuri nyore kusungirira kubva padhi;

Kunyanya kudzvinyirirwa kunoitwa nemusoro wesimbi wesimbi pane padhi uye nguva yakarebesa yewelding inobvisa padhi.