1. PCB kuburikidza negomba plating

Kune nzira dzakawanda dzekuvaka dhizaini yeplating inosangana nezvinodiwa pagomba madziro e substrate. Izvi zvinodaidzwa kuti gole wall activation mumaindasitiri ekushandisa. Yayo PCB board vagadziri vanoshandisa akawanda epakati ekuchengetedza matangi mukugadzira maitiro. Imwe neimwe tangi yekuchengetera Tangi ine yayo yekutonga nekugadzirisa zvinodiwa. Kuburikidza ne-hole electroplating ndiyo inotevera inodiwa yekugadzira maitiro ekuchera. Kana chibooreso chikadhirowa nepafoiri yemhangura uye nechikamu chiri pazasi, kupisa kunogadzirwa kunonyungudutsa iyo insulating synthetic resin inoumba hwaro hweakawanda substrates, resin yakanyungudutswa nezvimwe zvimedu zvekuchera Inoiswa yakatenderedza gomba uye yakaputirwa pagomba richangobva kubuda. rusvingo mune foil yemhangura, iyo inonyanya kukuvadza kune inotevera plating pamusoro.

Iyo resin yakanyungudutswa ichasiyawo dhizaini yeakisi inopisa pamadziro egomba re substrate, iyo inoratidza kusabatana kwakashata kune akawanda activator, izvo zvinoda kuvandudzwa kwekirasi yehunyanzvi hwakafanana nekubvisa tsvina uye etchback chemistry. Imwe nzira inonyanya kuenderana neiyo prototype yeakadhindwa edunhu mabhodhi ndeye kushandisa yakagadziridzwa yakaderera-viscosity ingi kuti iite inonamira uye inobatisisa coating pamadziro emukati emumwe nemumwe kuburikidza neburi. Nenzira iyi, hapana chikonzero chekushandisa maitiro akawanda emakemikari ekurapa, danho rimwe chete rekushandisa, rinoteverwa nekurapa kwekupisa, rinogona kuumba rinoramba richiputira mukati memadziro ose egomba, rinogona kuve rakananga electroplated pasina kuwedzera kurapwa. Ingi iyi iresin-based substance ine yakasimba adhesion uye inogona kusungirirwa nyore nyore kune yakawanda thermally polished gomba madziro, nokudaro kubvisa nhanho ye etch back.

2. Reel linkage type selective plating

Mapini nemapini ezvigadzirwa zvemagetsi, zvakaita semakonitani, maseketi akabatanidzwa, transistors, uye anochinjika FPCB mabhodhi, ese akaputirwa kuti awane yakanaka yekubata kupikisa uye kushora. Iyi nzira ye electroplating inogona kuve yemanyorero kana otomatiki, uye inodhura kwazvo kusarudza pini yega yega yekuisa, saka misa yemoto inofanira kushandiswa. Kazhinji, migumo miviri yesimbi foil yakakungurutswa kune inodiwa ukobvu inoroverwa, inocheneswa nemakemikari kana michina nzira, uye zvino yakasarudzika yakasarudzwa senge nickel, goridhe, sirivheri, rhodium, bhatani kana tin-nickel alloy, copper-nickel alloy , Nickel. -lead alloy, nezvimwewo zvekuenderera mberi plating. Mune electroplating nzira yekusarudza plating, kutanga kwezvose, jira rekudzivirira firimu rakaputirwa pane chikamu chesimbi yemhangura foil plate isingadi kuputirwa, uye chete yakasarudzwa yemhangura foil chikamu chinoputirwa.

3. Finger-plating plating

Iyo isingawanzo simbi inoda kuiswa pabhodhi edge yekubatanidza, iyo bhodhi mupendero inobuditsa kubata kana chigunwe chegoridhe kuti ipe yakaderera yekubata kuramba uye yakakwirira kupfeka kuramba. Iyi nzira inodaidzwa kunzi finger row plating kana kuti protruding part plating. Ndarama inowanzoputirwa pamabatiro anobuditsa emupendero wekubatanidza ne nickel plating pane yemukati layer. Chigunwe chegoridhe kana chikamu chakabudikira chemupendero webhodhi chinoshandisa tekinoroji kana otomatiki plating tekinoroji. Parizvino, iyo goridhe yakanamirwa pane yekubatanidza plug kana chigunwe chegoridhe chakaputirwa naambuya uye lead, Akapfava mabhatani panzvimbo.

Maitiro acho ndeaya:

1. Bvisa coating kuti ubvise tin kana tin-lead coating pane zvakabuda.

2. Shamba nemvura yekugeza.

3. Geza nemaabrasives.

4. Activation inonyudzwa mu10% sulfuric acid.

5. Hukobvu hwenickel plating pane anobuda macontacts ndeye 4-5μm.

6. Shamba uye bvisa mineral water.

7. Kurapa kwegoridhe kupinza mhinduro.

8. Kuisa goridhe.

9. Kuchenesa.

10. Kuomesa.

4. Brush plating

Inyanzvi ye electrodeposition, uye kwete zvikamu zvose zvinonyudzwa mu electrolyte panguva ye electroplating process. Mune iyi electroplating tekinoroji, ingori nzvimbo shoma inoiswa electroplated, uye haina mhedzisiro pane yasara. Kazhinji, simbi dzisina kujairika dzinoputirwa pazvikamu zvakasarudzwa zvebhodhi redunhu rakadhindwa, senge nzvimbo dzakadai sebhodhi edge connectors. Brush plating inoshandiswa kakawanda mukugadziriswa kwemarara ematunhu mabhodhi muzvitoro zvemagungano emagetsi. Putira yakakosha anode (anode isingaite makemikari, senge graphite) mune inonwisa zvinhu (cotton swab) uye shandisa iyo kuunza mhinduro yekuisa panzvimbo inodiwa plating.

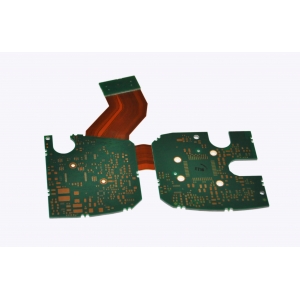

Fastline Circuits Co., Limited inyanzvi: PCB redunhu rekugadzira bhodhi rekugadzira, rinokupa: PCB proofing, batch system board, 1-34 layer PCB board, yakakwira TG board, impedance board, HDI board, Rogers board, Kugadzira uye kugadzirwa kwePCB edunhu mabhodhi akasiyana siyana. maitiro uye zvinhu zvakaita sema microwave board, radio frequency board, radar board, gobvu remhangura foil board, nezvimwe.