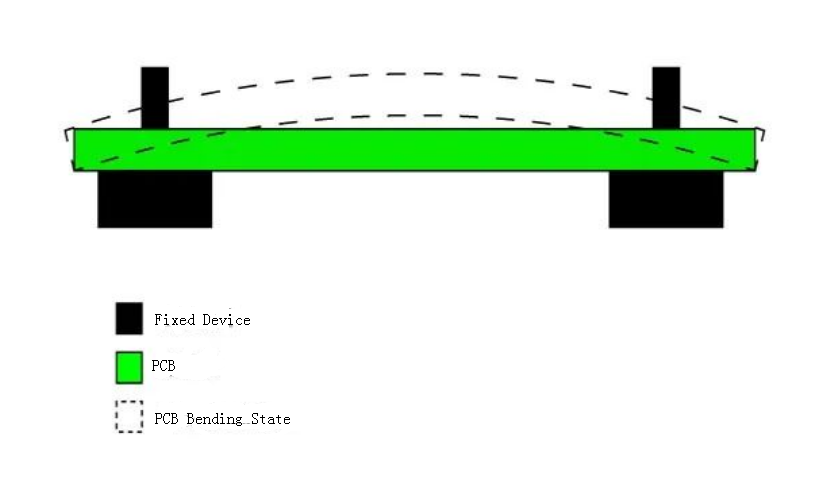

M'malo mwake, PCB warping imatanthawuzanso kupindika kwa bolodi lozungulira, lomwe limatanthawuza bolodi loyambira lathyathyathya. Akayikidwa pa desktop, malekezero awiri kapena pakati pa bolodi amawonekera pang'ono m'mwamba. Chodabwitsa ichi chimadziwika kuti PCB warping mumakampani.

The chilinganizo kuwerengetsera warpage gulu dera ndi kuyala bwalo dera lathyathyathya pa tebulo ndi ngodya zinayi za bolodi dera pansi ndi kuyeza kutalika kwa chipilala pakati. Fomula yake ndi iyi:

Warpage = kutalika kwa chipilala / kutalika kwa mbali ya PCB * 100%.

Circuit board warpage industry standard: Malinga ndi IPC — 6012(1996 edition) “Specification for Identification and Performance of Rigid Printed Boards”, kutha kwa nkhondo ndi kupotoza komwe kumaloledwa kupanga matabwa ozungulira kuli pakati pa 0.75% ndi 1.5%. Chifukwa cha kuthekera kosiyanasiyana kwa fakitale iliyonse, palinso kusiyana kofunikira pakuwongolera tsamba la PCB. Pakuti 1.6 bolodi wandiweyani ochiritsira awiri mbali multilayer dera matabwa, ambiri dera opanga bolodi kulamulira warpage PCB pakati 0.70-0.75%, ambiri SMT, BGA matabwa, zofunika mkati mwa osiyanasiyana 0,5%, mafakitale ena dera bolodi ndi amphamvu ndondomeko mphamvu akhoza kuukitsa PCB warpage muyezo mpaka 0.3%.

Kodi mungapewe bwanji warping wa bolodi dera pa kupanga?

(1) The theka-anachiza makonzedwe pakati pa wosanjikiza aliyense ayenera symmetrical, gawo la zigawo zisanu ndi chimodzi matabwa dera, makulidwe pakati 1-2 ndi 5-6 zigawo ndi chiwerengero cha theka-anachizidwa zidutswa ayenera kugwirizana;

2

3

Kodi mungapewe bwanji warping board board?

1.Kapangidwe kaumisiri: makonzedwe a interlayer semi-curing sheet ayenera kukhala oyenera; Multilayer core board ndi semi-cured sheet zidzapangidwa kuchokera kwa wothandizira yemweyo; Malo owonetsera ndege akunja a C / S ali pafupi kwambiri momwe angathere, ndipo gridi yodziimira yokha ingagwiritsidwe ntchito.

2.Drying mbale pamaso blank: zambiri 150 madigiri 6-10 maola, kupatula nthunzi madzi mu mbale, kuonjezera kupanga utomoni kuchiritsa kwathunthu, kuthetsa kupsyinjika mu mbale; Pepala lophika musanatsegule, zonse zamkati ndi mbali ziwiri zimafunikira!

3.Pamaso pa laminates, chidwi chiyenera kuperekedwa kwa njira yokhotakhota ndi yokhotakhota ya mbale yolimba: chiŵerengero cha warp ndi weft shrinkage sichifanana, ndipo tcheru chiyenera kuperekedwa kusiyanitsa njira yokhotakhota ndi yokhotakhota pamaso pa laminating pepala lokhazikika; Pakatikati mbale ayeneranso kulabadira malangizo a warp ndi weft; Mayendedwe onse a pepala lochiritsira mbale ndi njira ya meridian; Utali wautali wa mbale yachitsulo yamkuwa ndi yokhazikika; 10 zigawo za 4OZ mphamvu wandiweyani mkuwa pepala

4.the makulidwe a lamination kuthetsa nkhawa pambuyo ozizira kukanikiza, yokonza yaiwisi m'mphepete;

5.Kuphika mbale musanayambe kubowola: madigiri 150 kwa maola 4;

6.Ndi bwino kuti musadutse burashi yopera makina, kuyeretsa mankhwala kumalimbikitsidwa; Kukonzekera kwapadera kumagwiritsidwa ntchito pofuna kuteteza mbale kuti isapinde ndi kupindika

7.After kupopera mbewu mankhwalawa malata pa lathyathyathya nsangalabwi kapena zitsulo mbale zachilengedwe kuzirala kwa firiji kapena mpweya akuyandama bedi kuzirala pambuyo kuyeretsa;