1.

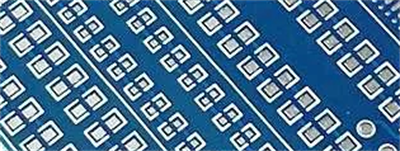

Nthawi zambiri imagwiritsidwa ntchito pomwe zigawozo zimachitika pa bolodi yosindikizidwa ndizazikulu ndipo ochepa, ndipo mzere wosindikizidwa ndi wosavuta. Mukapanga PCB ndi dzanja, pogwiritsa ntchito pad iyi ndikosavuta kukwaniritsa

2.

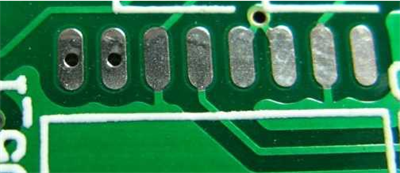

Kugwiritsidwa ntchito kwambiri m'mabodi amodzimodzimodzi ndi mbali ziwiri, magawowo amakonzedwa pafupipafupi. Ngati kuchuluka kwa bolodi kumalola, mapiritsi amatha kukhala okulirapo ndipo sadzagwa pakugulitsa.

3.

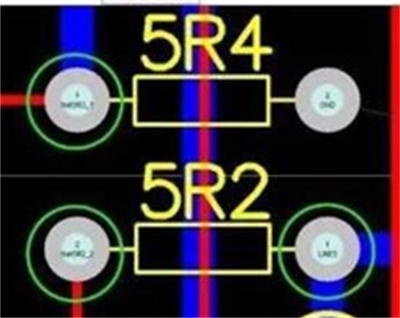

Maulalo a pad-ad pad amaphatikizidwa. Nthawi zambiri amagwiritsidwa ntchito pokonza zowongoka bwino.

4. Polygon pad

Amagwiritsidwa ntchito kusiyanitsa majekitake okhala ndi magawo akunja ofananira ndi maomwe osiyana ndi maomwe, omwe ndi abwino pokonza ndi msonkhano

5. Overthe padthed ili ndi malo okwanira kuti apititse patsogolo luso lotsutsa, lomwe limagwiritsidwa ntchito kawirikawiri mu zida zapakati

6.

Pofuna kuonetsetsa kuti pambuyo pa ntchito yogulitsira, mabowo a pad a ntchito yamanja sadzatsekedwa ndi msile.

7..

Mapada owoneka bwino amatchedwanso mapepala otentha, malo otentha a mpweya, etc. Ntchito yake ndikuchepetsa kutentha kwa mbale yotentha, ndikupewa kuwotcha kolakwika kapena pcb pespecation yoyambitsidwa kwambiri.

● Pambani yanu ikakhala pansi. Duwa looneka ngati mtanda limachepetsa gawo lolumikizira la waya, limachepetsa liwiro la kutentha, ndikuwongolera kuwala.

● Pamene PCB yanu ifuna kuyika makina ndikusowa makina ogulitsira, pad yolumikizidwa imatha kuletsa pcb kuchokera ku shuga (chifukwa madzi ambiri amafunikira kusungunula state)

8.. Teardrop Pad

Nthawi zambiri imagwiritsidwa ntchito ngati kufufuza kwake kumakhala kochepa thupi, kuteteza pensipo ndi kulumikizidwa kwa cholembera kuchokera pa chingwe. Izi zimagwiritsidwa ntchito nthawi zambiri pamabwalo apamwamba