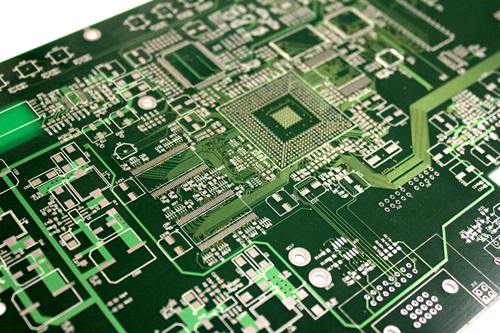

Kukula kwa zinthu zamagetsi akukhala woonda ndi ang'onoang'ono, ndipo mwachindunji stacking vias pa vias akhungu ndi kamangidwe njira mkulu-kachulukidwe interconnection. Kuti mugwire bwino ntchito yomanga mabowo, choyamba, kutsetsereka kwa pansi pa dzenje kuyenera kuchitidwa bwino. Pali njira zingapo zopangira, ndipo njira yodzaza dzenje la electroplating ndi imodzi mwazoyimira.

1. Ubwino wa electroplating ndi kudzaza dzenje:

(1) Zimathandiza kupanga mabowo odzaza ndi mabowo pa mbale;

(2) Kupititsa patsogolo ntchito zamagetsi ndikuthandizira mapangidwe apamwamba;

(3) imathandiza kuchotsa kutentha;

(4) Bowo la pulagi ndi kulumikiza magetsi kumatsirizidwa mu sitepe imodzi;

(5) Bowo lakhungu limadzazidwa ndi mkuwa wopangidwa ndi electroplated, womwe uli ndi kudalirika kwakukulu komanso kuwongolera bwino kuposa zomatira zomata.

2. Zolinga zakuthupi

Zomwe zimafunikira kuphunziridwa zikuphatikizapo: mtundu wa anode, mtunda pakati pa cathode ndi anode, kachulukidwe kamakono, chisokonezo, kutentha, rectifier ndi waveform, etc.

(1) Mtundu wa anode. Zikafika pamtundu wa anode, sichinthu choposa anode yosungunuka ndi anode osasungunuka. Manode osungunuka nthawi zambiri amakhala mipira yamkuwa yokhala ndi phosphorous, yomwe imakonda kukhala matope a anode, imaipitsa njira yopangira, komanso kukhudza magwiridwe antchito a plating. Anode osasungunuka, kukhazikika bwino, osafunikira kukonza kwa anode, osapanga matope a anode, oyenera kugunda kapena DC electroplating; koma madyedwe owonjezera ndi ochuluka.

(2) Cathode ndi anode spacing. Mapangidwe a malo pakati pa cathode ndi anode mu njira yodzaza dzenje la electroplating ndizofunikira kwambiri, komanso mapangidwe a zida zamitundu yosiyanasiyana ndi osiyana. Ziribe kanthu momwe zinapangidwira, siziyenera kuphwanya lamulo loyamba la Farah.

(3) Kusokoneza. Pali mitundu yambiri ya kugwedezeka, kuphatikizapo kugwedezeka kwamakina, kugwedezeka kwamagetsi, kugwedezeka kwa pneumatic, kugwedeza mpweya, kutuluka kwa ndege ndi zina zotero.

Podzaza dzenje la electroplating, nthawi zambiri amakonda kuwonjezera kapangidwe ka jet kutengera masinthidwe a silinda yachikhalidwe yamkuwa. Chiwerengero, malo ndi ngodya ya jets pa chubu cha jet ndi zinthu zonse zomwe ziyenera kuganiziridwa popanga silinda yamkuwa, ndipo mayesero ambiri ayenera kuchitidwa.

(4) Kachulukidwe ndi kutentha kwapano. Kachulukidwe kakang'ono kapano komanso kutentha kochepa kumatha kuchepetsa kuchuluka kwa mkuwa pamtunda, pomwe kumapereka Cu2 yokwanira komanso yowunikira mu pores. Pansi pazimenezi, luso la kudzaza dzenje limakulitsidwa, koma plating imachepetsanso.

(5) Wokonzanso. The rectifier ndi ulalo wofunika mu njira electroplating. Pakadali pano, kafukufuku wokhudza kudzaza dzenje ndi electroplating nthawi zambiri amangokhala ndi ma electroplating a board. Ngati kudzazidwa kwa dzenje kumaganiziridwa, dera la cathode lidzakhala laling'ono kwambiri. Panthawiyi, zofunikira kwambiri zimayikidwa pa kulondola kwa zotsatira za rectifier.Kulondola kwa zotsatira za rectifier ziyenera kusankhidwa molingana ndi mzere wa mankhwala ndi kukula kwa dzenje. Mizere yocheperako komanso mabowo ang'onoang'ono, m'pamenenso amafunikira kuwongolera bwino kwa wowongolera. Nthawi zambiri, ndikofunikira kusankha chowongolera ndi kulondola kotulutsa mkati mwa 5%.

(6) Waveform. Pakalipano, malinga ndi mawonekedwe a waveform, pali mitundu iwiri ya electroplating ndi mabowo odzaza: pulse electroplating ndi Direct current electroplating. Chowongolera chachikhalidwe chimagwiritsidwa ntchito popanga plating mwachindunji ndikudzaza mabowo, omwe ndi osavuta kugwiritsa ntchito, koma ngati mbaleyo ili yokhuthala, palibe chomwe chingachitike. PPR rectifier imagwiritsidwa ntchito popanga ma pulse electroplating ndi kudzaza dzenje, ndipo pali njira zambiri zogwirira ntchito, koma ili ndi kuthekera kolimba kwa matabwa okulirapo.