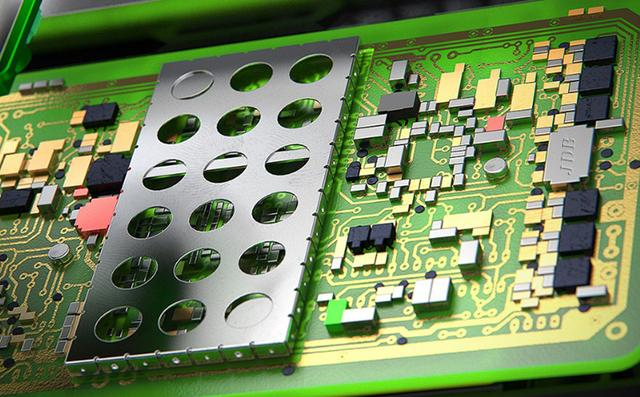

In the process of SMT chip processing, short circuit is a very common poor processing phenomenon. The short circuited PCBA circuit board cannot be used normally. The following is a common inspection method for short circuit of PCBA board.

1. It is recommended to use a short circuit positioning analyzer to check the poor condition.

2. In case of a large number of short circuits, it is recommended to take a circuit board to cut the wires, and then power on each area to check the areas with short circuits one by one.

3. It is recommended to use a multimeter to detect whether the key circuit is short circuited. Every time the SMT patch is completed, the IC needs to use a multimeter to detect whether the power supply and ground are short circuited.

4. Light up the short circuit network on the PCB diagram, check the position on the circuit board where the short circuit is most likely to occur, and pay attention to whether there is a short circuit inside the IC.

5. Be sure to carefully weld those small capacitive components, otherwise the short circuit between the power supply and the ground is very likely to occur.

6. If there is a BGA chip, because most of the solder joints are covered by the chip and are not easy to see, and they are multilayer circuit boards, it is recommended to cut off the power supply of each chip in the design process, and connect them with magnetic beads or 0 ohm resistance. In case of short circuit, disconnecting the magnetic bead detection will make it easy to locate the chip on the circuit board.