According to the developed circuit diagram, the simulation can be performed and the PCB can be designed by exporting the Gerber/drill file. Whatever the design, engineers need to understand exactly how the circuits (and electronic components) should be laid out and how they work. For electronics engineers, finding the right software tools for PCB design can be a daunting task. Software tools that work well for one PCB project may not work well for others. Engineers want board design tools that are intuitive, contain useful features, are stable enough to limit risk, and have a robust library that makes them suitable for multiple projects.

Hardware problem

For iot projects, integration is critical for performance and reliability, and the integration of conductive and non-conductive materials in PCBS requires iot designers to study the interactions between the various electrical and mechanical aspects of the design. In particular, as component sizes continue to shrink, electric heating on PCBS is becoming increasingly critical. At the same time, functional requirements are rising. To achieve the performance-based performance of the design, temperature response, the behavior of the electrical components on the board, and overall thermal management are critical to the functionality and reliability of the system.

PCB must be isolated to ensure protection. Short circuits are prevented by protecting the copper traces placed on the board to create the electronic system. Compared to low-cost alternatives such as synthetic resin adhesive paper (SRBP, FR-1, FR-2), FR-4 is more suitable as a substrate material due to its physical/mechanical properties, especially the ability to retain data at high frequencies, its high heat resistance, and the fact that it absorbs less water than other materials. The FR-4 is widely used in high-end buildings as well as industrial and military equipment. It is compatible with ultra-high insulation (ultra-high vacuum or UHV).

However, FR-4 as a PCB substrate faces a number of limitations, which stem from the chemical treatment used in production. In particular, the material is prone to the formation of inclusions (bubbles) and streaks (longitudinal bubbles), as well as the deformation of the glass fiber. These defects can cause inconsistent dielectric strength and impair PCB wiring performance. The new epoxy glass material solves these problems.

Other commonly used materials include polyimide/glass fiber (which supports higher temperatures and is harder) and KAPTON (flexible, lightweight, suitable for applications such as displays and keyboards). Factors to consider when selecting dielectric materials (substrates) include coefficient of thermal expansion (CTE), glass transition temperature (Tg), thermal conductivity, and mechanical rigidity.

Military/aerospace PCBS require special design considerations based on layout specifications and 100% Design for Test (DFT) coverage. The MIL-STD-883 standard establishes methods and procedures for testing microelectronic devices suitable for military and aerospace systems, including mechanical and electrical testing, manufacturing and training procedures, and other controls to ensure consistent levels of quality and reliability throughout the system. Various applications of such devices.

In addition to meeting various standards, the design of automotive system electronics must follow a series of rules, such as the AEC-Q100 mechanical and electronic test for packaging integrated circuits. Crosstalk effects can interfere with vehicle safety. To minimize these effects, PCB designers must specify a distance between the signal line and the power line. Design and standardization are facilitated by software tools that automatically highlight aspects of the design that need further modification to meet interference limitations and heat dissipation conditions to avoid affecting system operation.

Notes:

Interference from the circuit itself is not a threat to signal quality. The PCB in the car is bombarded with noise, which interacts with the body in complex ways to induce unwanted current in the circuit. Voltage spikes and fluctuations caused by automotive ignition systems can push components far beyond their machining tolerances.

Software problem

Today’s PCB layout tools must have multiple functional combinations to meet the requirements of designers. Choosing the right layout tool should be the first consideration in PCB design and should never be overlooked. Products from Mentor Graphics, OrCAD Systems, and Altium are among today’s PCB layout tools.

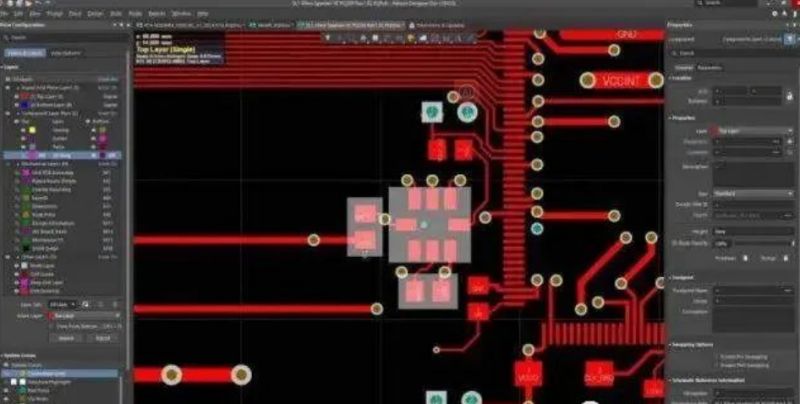

Altium Designer

Altium Designer is one of the high-end PCB design packages on the market today. With automatic wiring function, support for line length adjustment and 3D modeling. Altium Designer includes tools for all circuit design tasks, from schematic capture to HDL as well as circuit simulation, signal analysis, PCB design, and FPGA embedded development

Mentor Graphics’ PCB layout platform addresses the main challenges facing today’s system designers: accurate, performance – and reuse-oriented nested planning; Efficient routing in dense and complex topologies; And electromechanical optimization. A key feature of the platform and a key innovation for the industry is the Sketch Router, which gives designers full interactive control over the automatic/assisted uncoiling process, producing the same quality results as manual uncoiling, but in much less time.

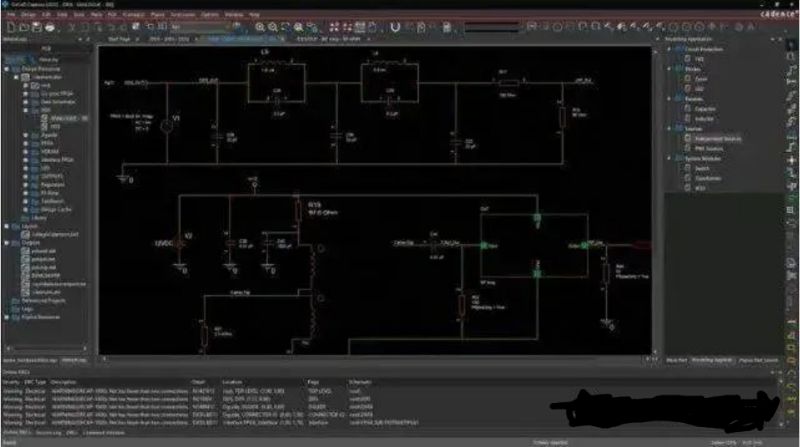

OrCAD PCB Editor

OrCAD PCB Editor is an interactive environment developed for board design at any technical level, from simple to complex. Due to its true scalability to Cadence Allegro PCB Designer’s PCB solutions, OrCAD PCB Editor supports the technical development of design teams and is able to manage constraints (high speed, signal integrity, etc.) while maintaining the same graphical interface and file format

Gerber file

The industry standard Gerber file format is used to convey design information for PCB production. In many ways, Gerber is similar to PDFS in electronics; It’s just a small file format written in a mixed machine control language. These files are generated by the circuit breaker software and sent to the PCB manufacturer to the CAM software.

Safely integrating electronic systems into vehicles and other complex systems presents important considerations for both hardware and software. Engineers aim to minimize the number of design iterations and development time, which has significant advantages for designers implementing workflows.