News

-

How to make the most cost-effective PCB project? !

As a hardware designer, the job is to develop PCBs on time and within budget, and they need to be able to work normally! In this article, I will explain how to consider the manufacturing issues of the circuit board in the design, so that the cost of the circuit board is lower without affecting th...Read more -

PCB manufacturers have laid out Mini LED industry chain

Apple is about to launch Mini LED backlight products, and TV brand manufacturers have also successively introduced Mini LED. Previously, some manufacturers have launched Mini LED notebooks, and related business opportunities have gradually emerged. The legal person expects that PCB factories such...Read more -

Knowing this, do you dare to use expired PCB?

This article mainly introduces three hazards of using expired PCB. 01 Expired PCB may cause surface pad oxidation Oxidation of the soldering pads will cause poor soldering, which may eventually lead to functional failure or risk of dropouts. Different surface treatments of circuit boards w...Read more -

Why does PCB dump copper?

A. PCB factory process factors 1. Excessive etching of copper foil The electrolytic copper foil used in the market is generally single-sided galvanized (commonly known as ashing foil) and single-sided copper plating (commonly known as red foil). The common copper foil is generally galvanized copp...Read more -

How to reduce PCB design risks?

During the PCB design process, if possible risks can be predicted in advance and avoided in advance, the success rate of PCB design will be greatly improved. Many companies will have an indicator of the success rate of PCB design one board when evaluating projects. The key to improving the succe...Read more -

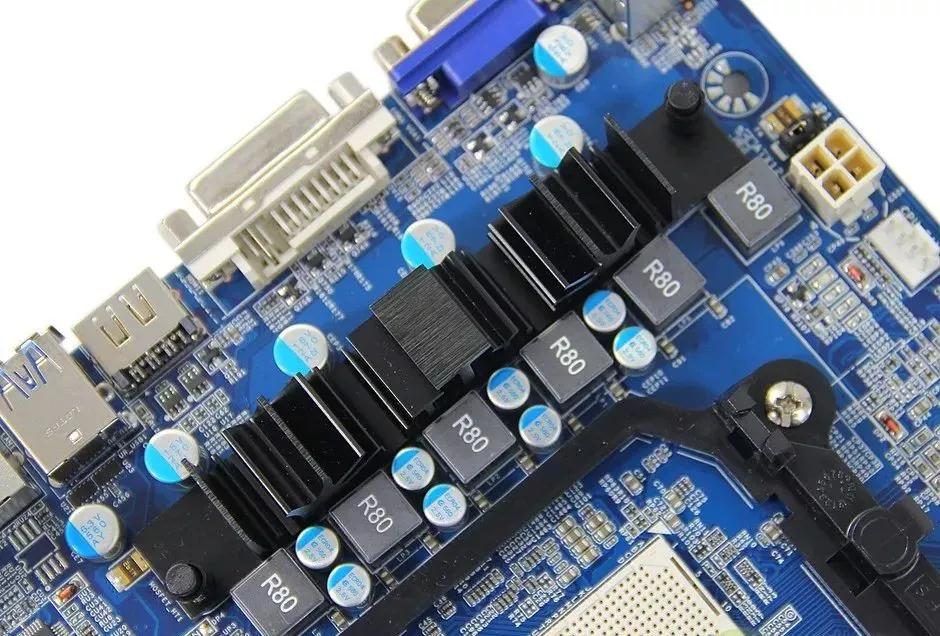

SMT skills 丨 component placement rules

In PCB design, the layout of components is one of the important links. For many PCB engineers, how to lay out components reasonably and effectively has its own set of standards. We summed up the layout skills, roughly the following 10 The layout of electronic components needs to be follow...Read more -

What role do those “special pads” on the PCB play?

1. Plum blossom pad. 1: The fixing hole needs to be non-metallized. During wave soldering, if the fixing hole is a metalized hole, tin will block the hole during reflow soldering. 2. Fixing mounting holes as quincunx pads is generally used for mounting hole GND network, because generally...Read more -

Why does PCB design generally control 50 ohm impedance?

In the process of PCB design, before routing, we generally stack the items we want to design, and calculate the impedance based on the thickness, substrate, number of layers and other information. After the calculation, the following content can generally be obtained. As can be see...Read more -

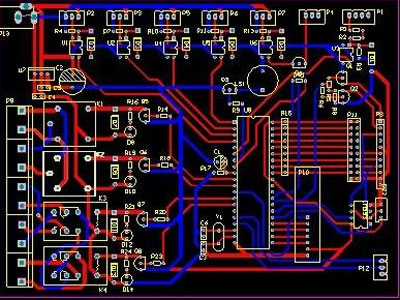

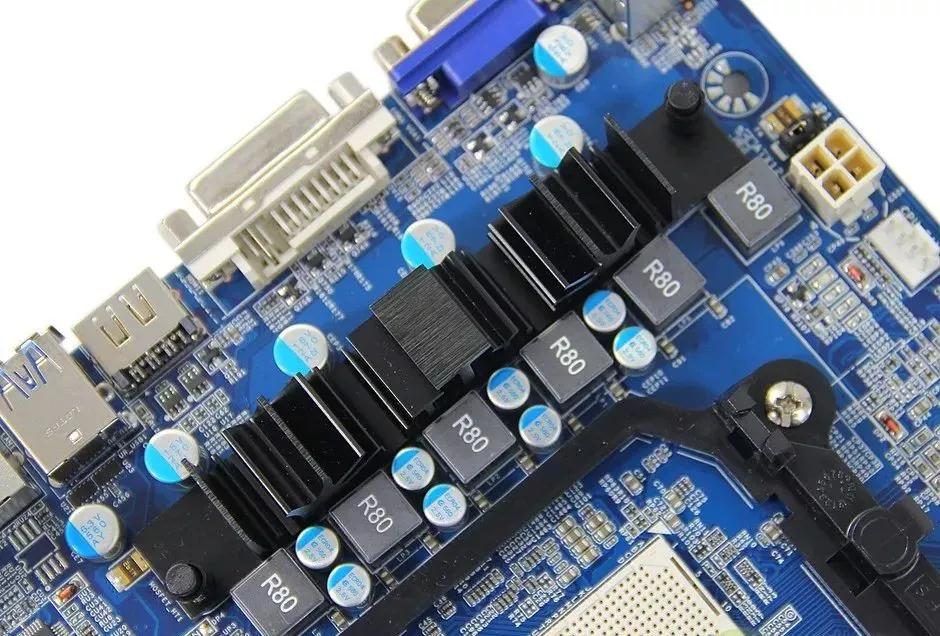

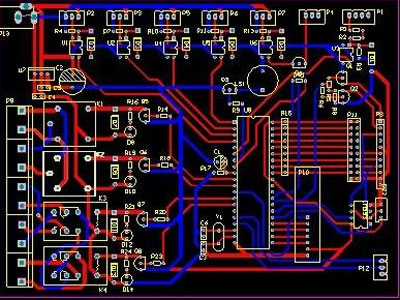

How to reverse the schematic diagram of PCB copy board

PCB copy board, the industry is often referred to as circuit board copy board, circuit board clone, circuit board copy, PCB clone, PCB reverse design or PCB reverse development. That is, on the premise that there are physical objects of electronic products and circuit boards, reverse analysis of ...Read more -

Analysis of three main reasons for PCB rejection

The PCB copper wire falls off (also commonly referred to as dumping copper). PCB factories all say that it is a laminate problem and requires their production factories to bear bad losses. 1. The copper foil is over-etched. The electrolytic copper foil used in the market is generally singl...Read more -

PCB industry terms and definitions: DIP and SIP

Dual in-line package (DIP) Dual-in-line package (DIP—dual-in-line package), a package form of components. Two rows of leads extend from the side of the device and are at right angles to a plane parallel to the body of the component. The chip adopting this packaging method has two rows of pins, w...Read more -

Wearable device requirements for PCB materials

Due to the small size and size, there are almost no existing printed circuit board standards for the growing wearable IoT market. Before these standards came out, we had to rely on the knowledge and manufacturing experience learned in board-level development and think about how to apply them to u...Read more