News

-

5 tips can help you reduce PCB manufacturing costs.

01 Minimize the board size One of the main factors that can have a significant impact on production costs is the size of the printed circuit board. If you need a larger circuit board, the wiring will be easier, but the production cost will also be higher. vice versa. If your PCB is too small, a...Read more -

Disassemble iPhone 12 and iPhone 12 Pro to see whose PCB is inside

The iPhone 12 and iPhone 12 Pro were just launched, and the well-known dismantling agency iFixit immediately conducted a dismantling analysis of the iPhone 12 and iPhone 12 Pro. Judging from the dismantling results of iFixit, the new machine’s workmanship and materials are still excellent, ...Read more -

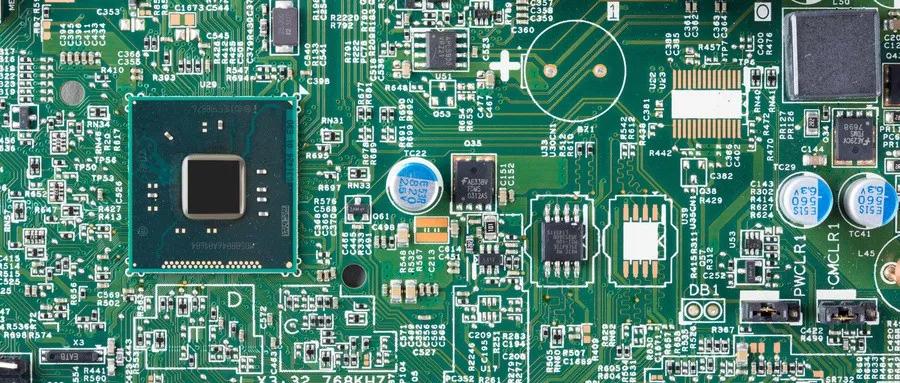

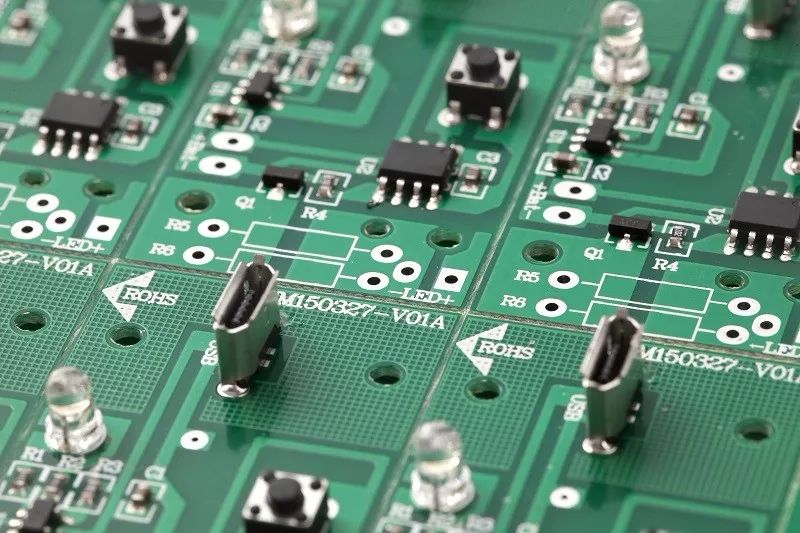

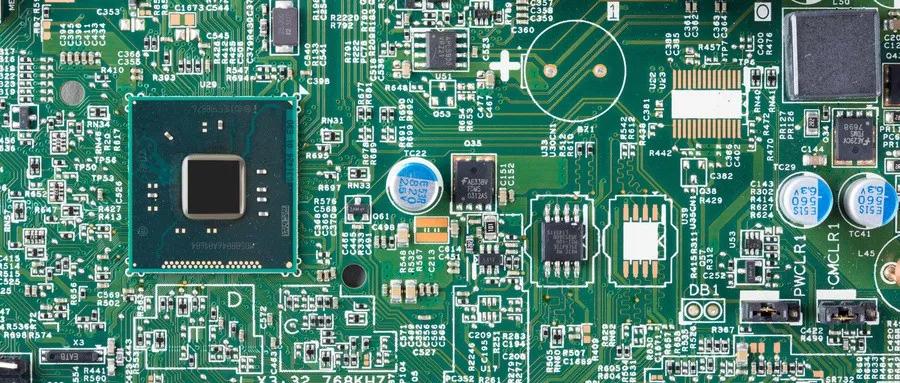

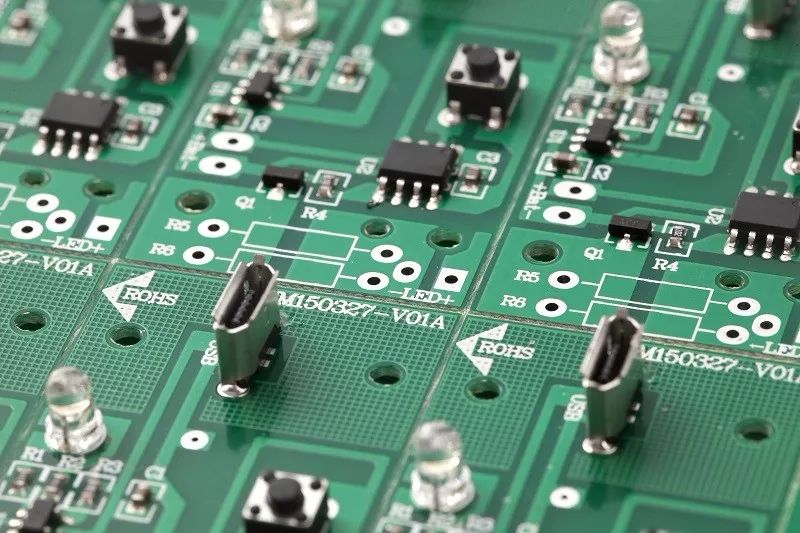

Basic rules of component layout

1. Layout according to circuit modules, and related circuits that realize the same function are called a module. The components in the circuit module should adopt the principle of nearby concentration, and the digital circuit and the analog circuit should be separated; 2. No components or devices...Read more -

How to use copper weight to make high-end PCB manufacturing ?

For many reasons, there are many different types of PCB manufacturing projects that require specific copper weights. We receive questions from customers who are not familiar with the concept of copper weight from time to time, so this article aims to solve these problems. In addition, the followi...Read more -

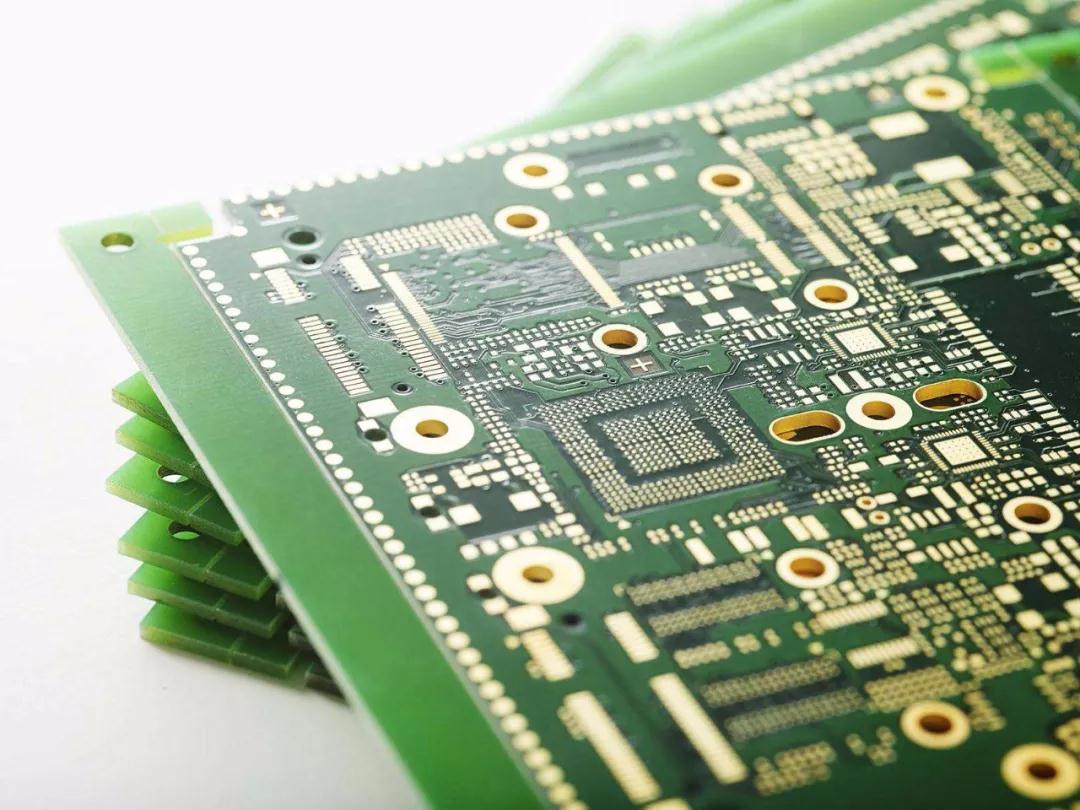

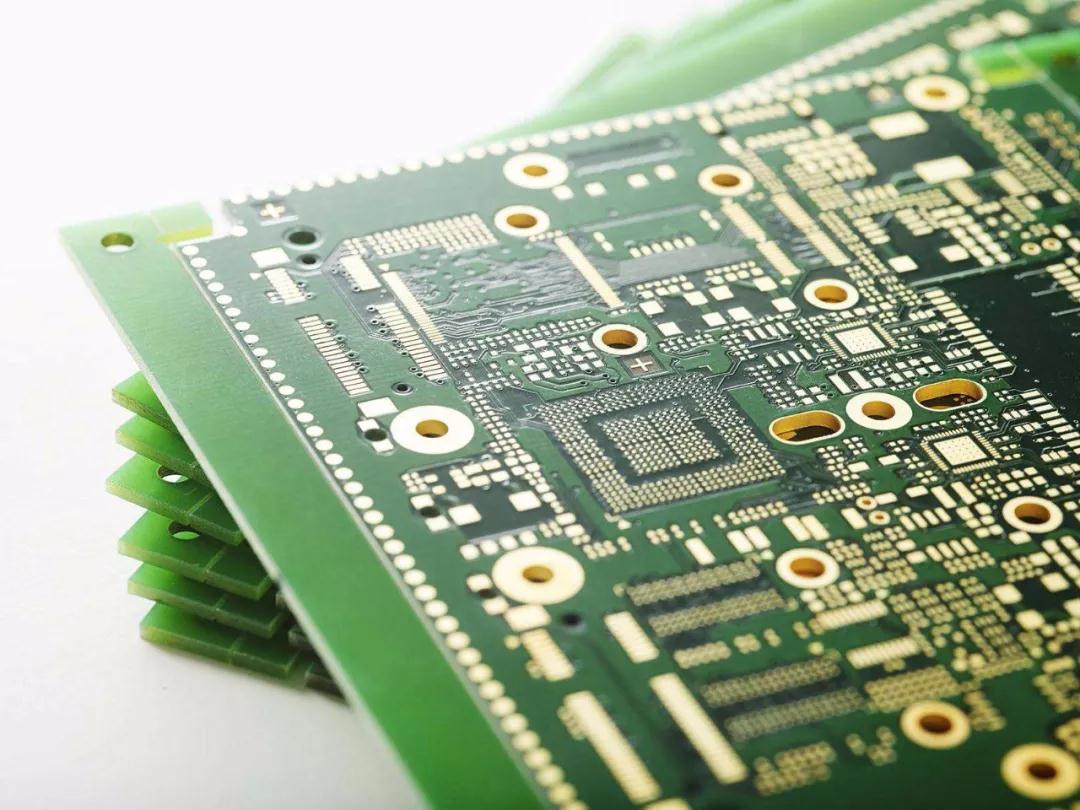

Pay attention to these things about PCB “layers”!

The design of a multilayer PCB (printed circuit board) can be very complicated. The fact that the design even requires the use of more than two layers means that the required number of circuits will not be able to be installed only on the top and bottom surfaces. Even when the circuit does fit in...Read more -

Specification terms for materials of 12-layer PCB

Several material options can be used to customize 12-layer PCB boards. These include different kinds of conductive materials, adhesives, coating materials, and so on. When specifying material specifications for 12-layer PCBs, you may find that your manufacturer uses many technical terms. You must...Read more -

PCB stackup design method

The laminated design mainly complies with two rules: 1. Each wiring layer must have an adjacent reference layer (power or ground layer); 2. The adjacent main power layer and ground layer should be kept at a minimum distance to provide larger coupling capacitance; The following lists the st...Read more -

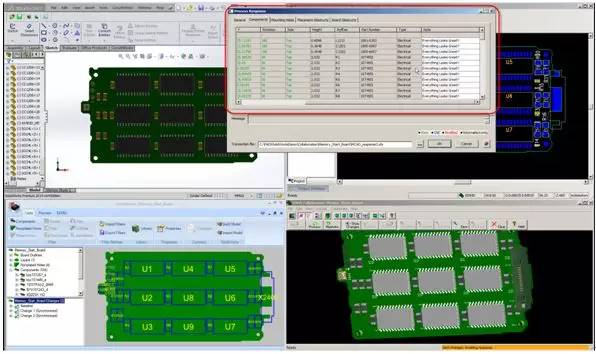

How to quickly determine the number of layers, wiring and layout of the PCB?

As PCB size requirements become smaller and smaller, device density requirements become higher and higher, and PCB design becomes more difficult. How to achieve a high PCB layout rate and shorten the design time, then we will talk about the design skills of PCB planning, layout and wiring.Read more -

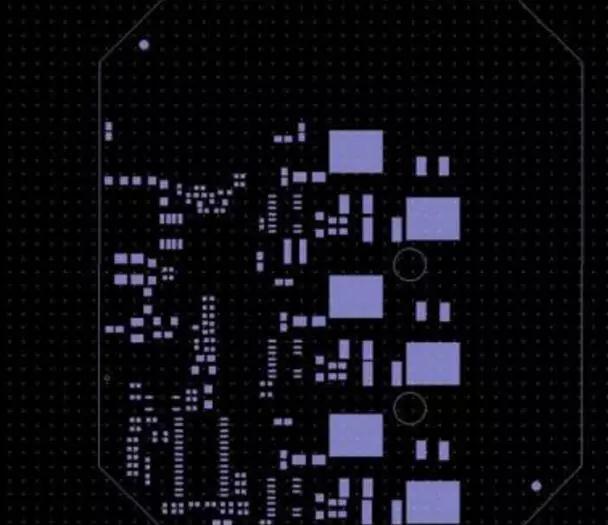

The difference and function of circuit board soldering layer and solder mask

Introduction to Solder Mask The resistance pad is soldermask, which refers to the part of the circuit board to be painted with green oil. In fact, this solder mask uses a negative output, so after the shape of the solder mask is mapped to the board, the solder mask is not painted with green oil, ...Read more -

PCB plating has several methods

There are four main electroplating methods in circuit boards: finger-row electroplating, through-hole electroplating, reel-linked selective plating, and brush plating. Here is a brief introduction: 01 Finger row plating Rare metals need to be plated on the board edge connectors, board ed...Read more -

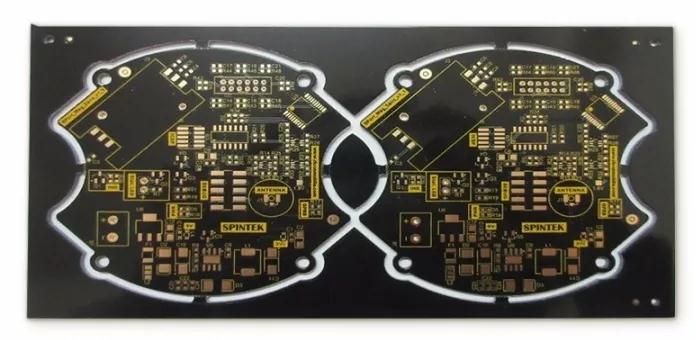

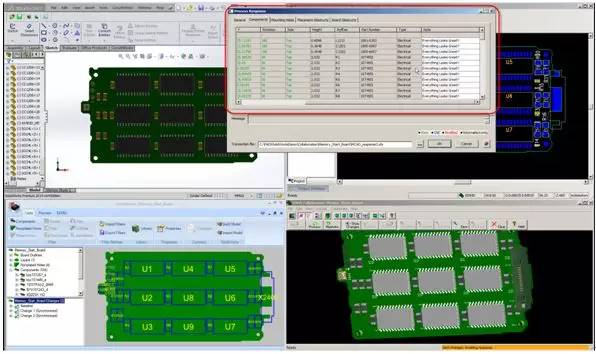

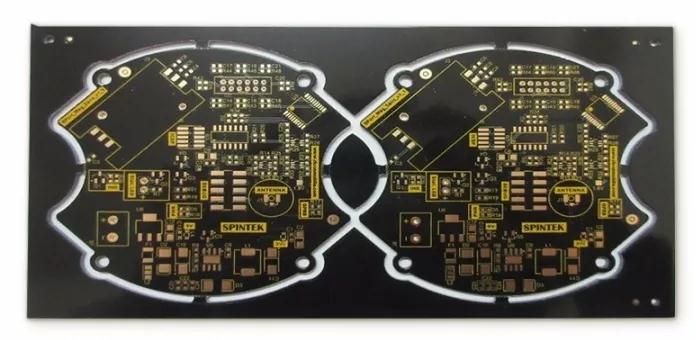

Quickly learn irregular-shaped PCB design

The complete PCB we envision is usually a regular rectangular shape. Although most designs are indeed rectangular, many designs require irregularly shaped circuit boards, and such shapes are often not easy to design. This article describes how to design irregular-shaped PCBs. Nowadays, the size o...Read more -

Through hole, blind hole, buried hole, what are the characteristics of the three PCB drilling?

Via (VIA), this is a common hole used to conduct or connect copper foil lines between conductive patterns in different layers of the circuit board. For example (such as blind holes, buried holes), but can not insert component leads or copper-plated holes of other reinforced materials. Because the...Read more