News

-

electrically conduc- tive printing ink notes

According to the actual experience of ink used by most manufacturers, the following regulations must be followed when using ink: 1. In any case, the temperature of the ink must be kept below 20-25°C, and the temperature cannot change too much, otherwise it will affect the viscosity of the ink and...Read more -

Is the “gold” of gold fingers gold?

Gold Finger On computer memory sticks and graphics cards, we can see a row of golden conductive contacts, which are called “golden fingers”. The Gold Finger (or Edge Connector) in the PCB design and production industry uses the connector of the connector as the outlet for the board to...Read more -

What exactly are the colors of PCB?

What is the color of the PCB board, as the name suggests, when you get a PCB board, the most intuitively you can see the oil color on the board, which is what we generally refer to as the color of the PCB board. Common colors include green, blue, red and black, etc. Wait. 1. Green ink is by far t...Read more -

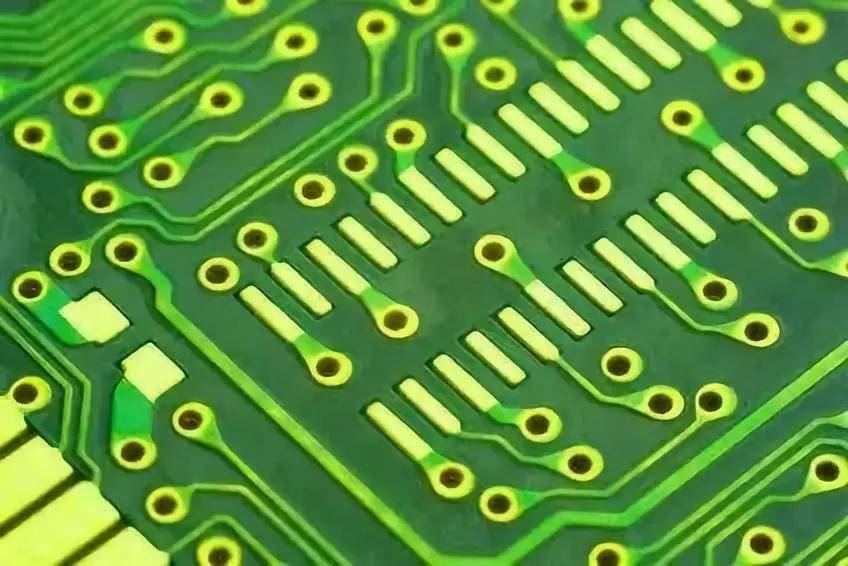

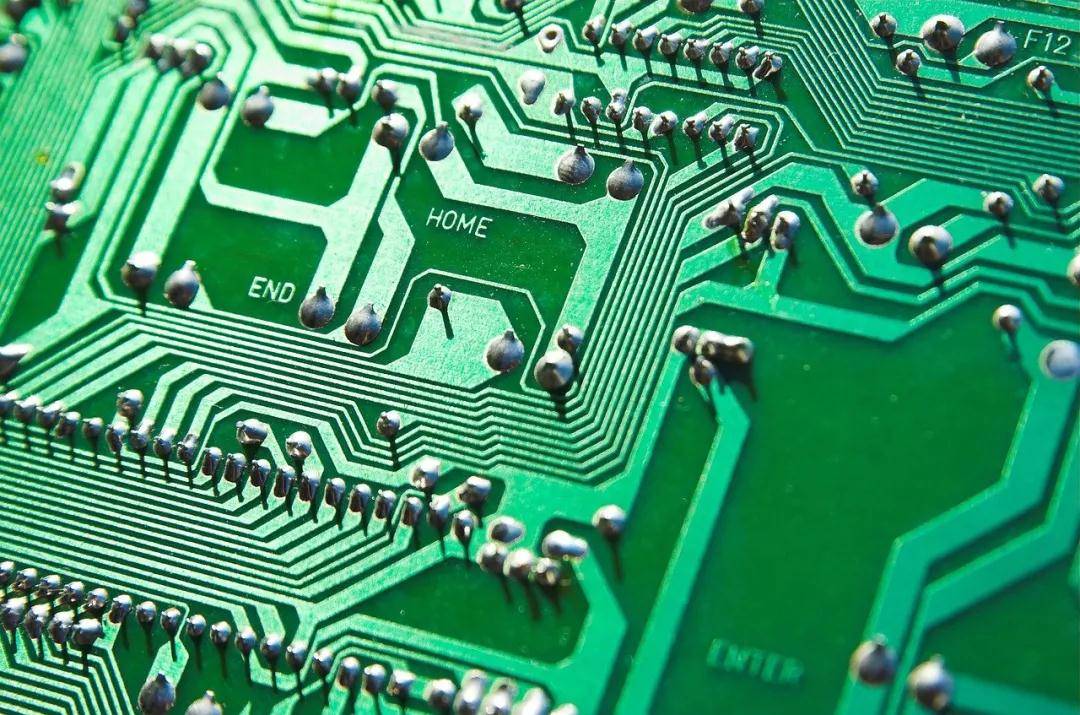

What is the significance of the PCB plugging process?

Conductive hole Via hole is also known as via hole. In order to meet customer requirements, the circuit board via hole must be plugged. After a lot of practice, the traditional aluminum plugging process is changed, and the circuit board surface solder mask and plugging are completed with white me...Read more -

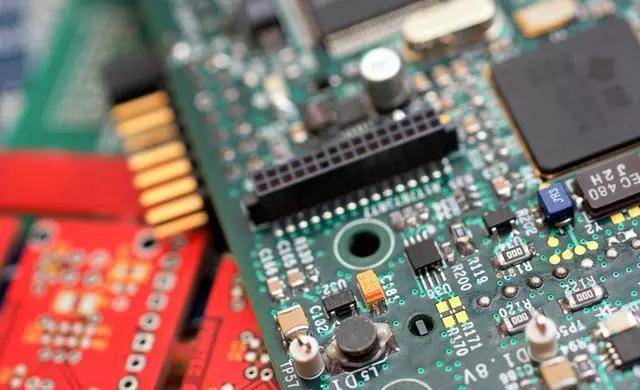

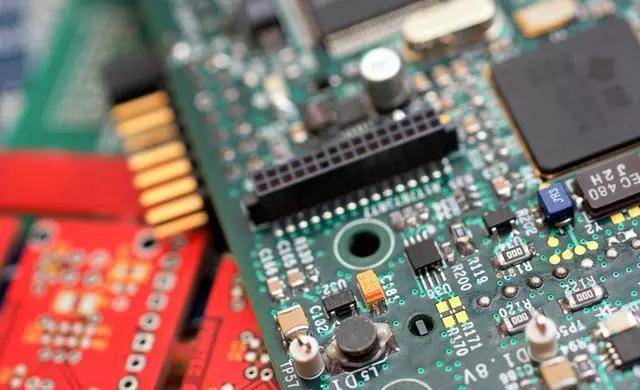

What are the benefits of gold plating and silver plating on PCB boards?

Many DIY players will find that the PCB colors used by the various board products in the market are dazzling. The more common PCB colors are black, green, blue, yellow, purple, red and brown. Some manufacturers have ingeniously developed PCBs of different colors such as white and pink. In ...Read more -

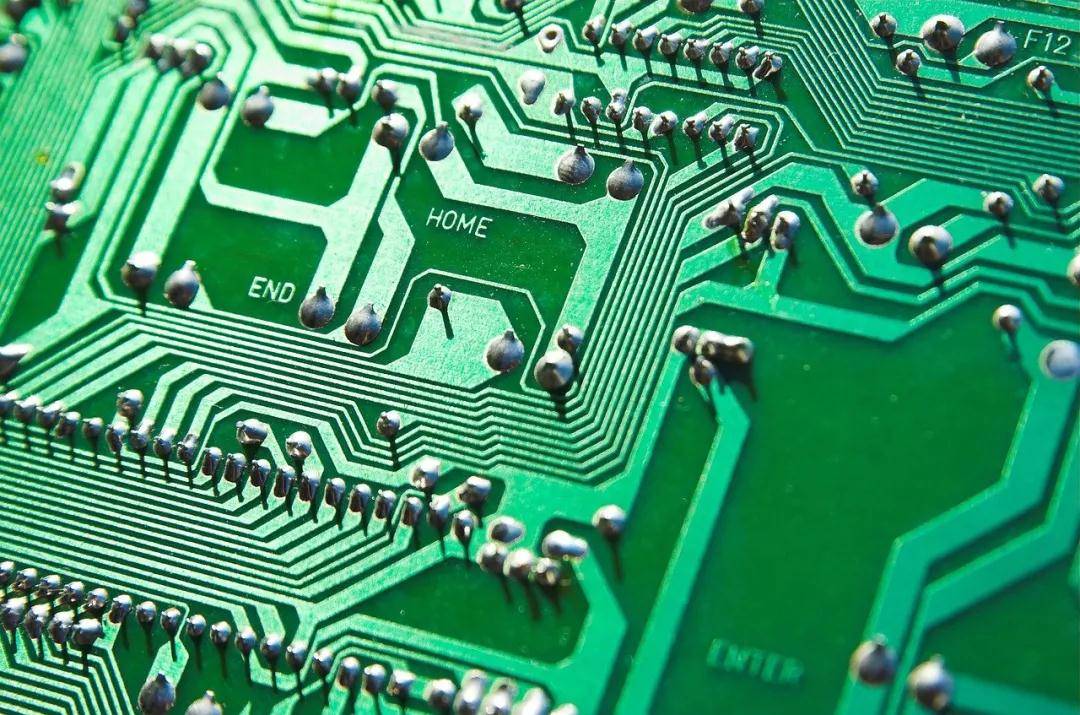

It only takes one minute to make a PCB in this way!

1. Draw the PCB circuit board: 2. Set to print only TOP LAYER and via layer. 3. Use a laser printer to print on thermal transfer paper. 4. The thinnest electrical circuit set on this circuit board is 10mil. 5. The one-minute plate-making time starts from the black-and-white image of the electroni...Read more -

Eight common problems and solutions in PCB design

In the process of PCB design and production, engineers not only need to prevent accidents during PCB manufacturing, but also need to avoid design errors. This article summarizes and analyzes these common PCB problems, hoping to bring some help to everyone’s design and production work. ...Read more -

PCB printing process advantages

From PCB World. Inkjet printing technology has been widely accepted for the marking of PCB circuit boards and solder mask ink printing. In the digital age, the demand for instantaneous reading of edge codes on a board-by-board basis and instant generation and printing of QR codes has made ...Read more -

Thailand occupies 40% of Southeast Asia’s PCB production capacity, ranking among the top ten in the world

From PCB World. Supported by Japan, Thailand’s automobile production was once comparable to France’s, replacing rice and rubber to become Thailand’s largest industry. Both sides of Bangkok Bay are lined with automobile production lines of Toyota, Nissan and Lexus, a boiling sc...Read more -

The difference between PCB schematic and PCB design file

From PCBworld When talking about printed circuit boards, novices often confuse “PCB schematics” and “PCB design files”, but they actually refer to different things. Understanding the differences between them is the key to successfully manufacturing PCBs, so in order for be...Read more -

About PCB baking

1. When baking large-size PCBs, use a horizontal stacking arrangement. It is recommended that the maximum number of a stack should not exceed 30 pieces. The oven needs to be opened within 10 minutes after baking to take out the PCB and lay it flat to cool it. After baking, it needs to be presse...Read more -

Why do expired PCBs need to be baked before SMT or furnace?

The main purpose of PCB baking is to dehumidify and remove moisture, and to remove the moisture contained in the PCB or absorbed from the outside, because some materials used in the PCB itself easily form water molecules. In addition, after the PCB is produced and placed for a period of time, the...Read more