News

-

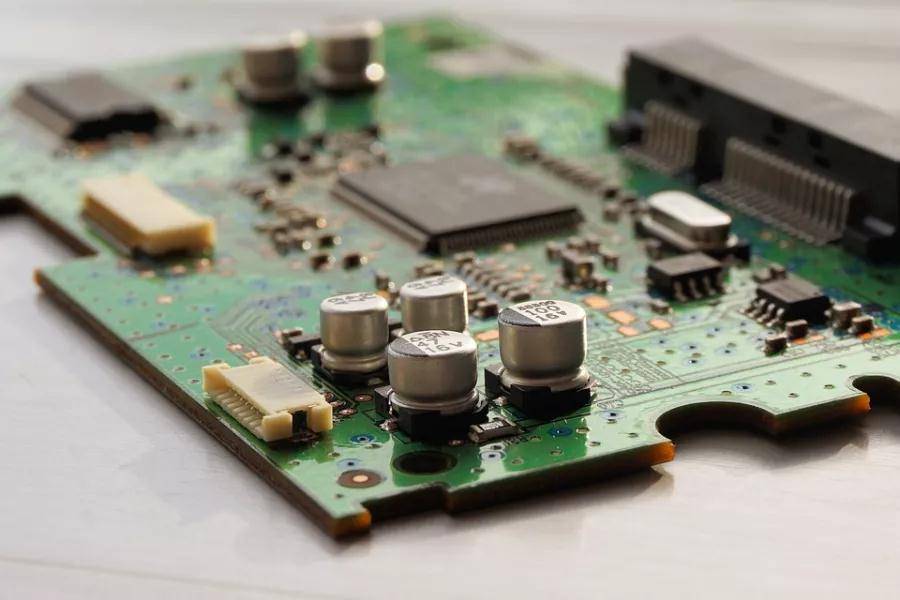

Why bake PCB? How to bake good quality PCB

The main purpose of PCB baking is to dehumidify and remove moisture contained in the PCB or absorbed from the outside world, because some materials used in the PCB itself easily form water molecules. In addition, after the PCB is produced and placed for a period of time, there is a chance to abso...Read more -

The most eye-catching PCB products in 2020 will still have high growth in the future

Among the various products of global circuit boards in 2020, the output value of substrates is estimated to have an annual growth rate of 18.5%, which is the highest among all products. The output value of substrates has reached 16% of all products, second only to multilayer Board and soft board....Read more -

Cooperate with the customer’s process adjustment to solve the problem of falling off printing characters

In recent years, the application of inkjet printing technology to the printing of characters and logos on PCB boards has continued to expand, and at the same time it has raised higher challenges to the completion and durability of inkjet printing. Because of its ultra-low viscosity, the inkjet pr...Read more -

9 tips for basic PCB board testing

It is time for PCB board inspection to pay attention to some details in order to be more prepared to ensure product quality. When inspecting PCB boards, we should pay attention to the following 9 tips. 1. It is strictly forbidden to use grounded test equipment to touch the live TV, audio, video a...Read more -

99% of PCB design failures are caused by these 3 reasons

As engineers, we have thought of all the ways that the system can fail, and once it fails, we are ready to repair it. Avoiding faults is more important in PCB design. Replacing a circuit board that is damaged in the field can be expensive, and customer dissatisfaction is usually more expensive. T...Read more -

RF board laminate structure and wiring requirements

In addition to the impedance of the RF signal line, the laminated structure of the RF PCB single board also needs to consider issues such as heat dissipation, current, devices, EMC, structure and skin effect. Usually we are in the layering and stacking of multilayer printed boards. Follow some ba...Read more -

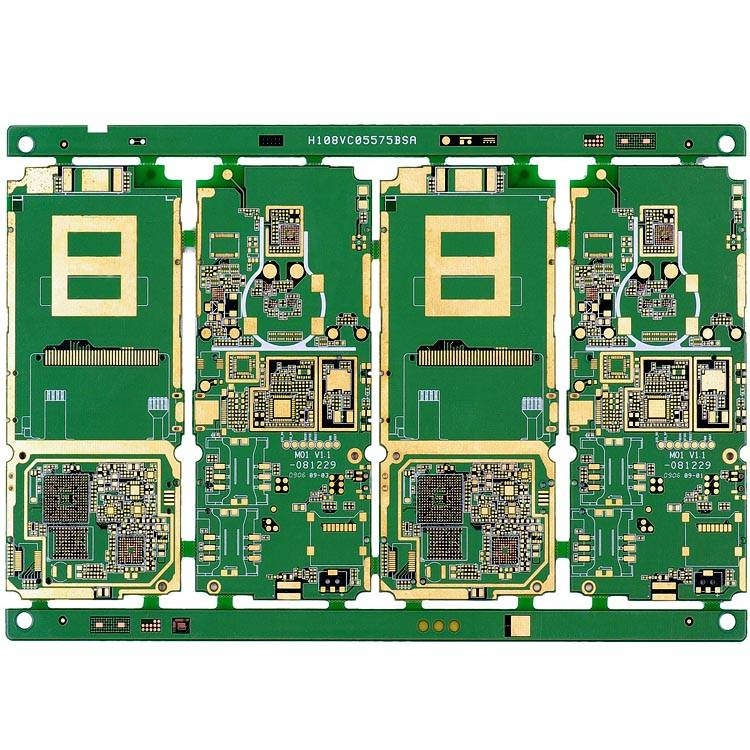

How is the inner layer of the PCB made

Due to the complex process of PCB manufacturing, in the planning and construction of intelligent manufacturing, it is necessary to consider the related work of process and management, and then carry out automation, information and intelligent layout. Process classification According to the num...Read more -

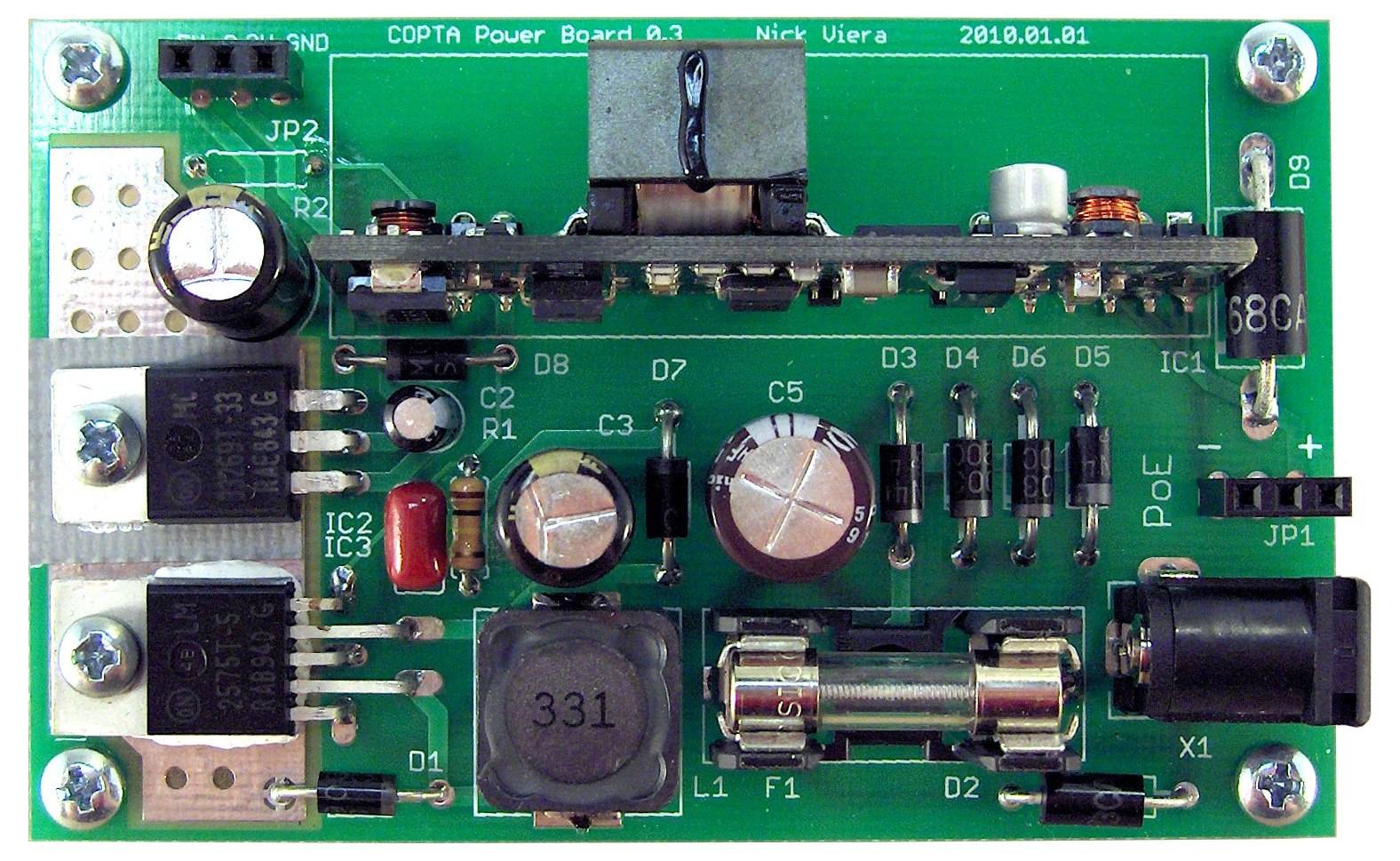

PCB wiring process requirements (can be set in the rules)

(1) Line In general, the signal line width is 0.3mm (12mil), the power line width is 0.77mm (30mil) or 1.27mm (50mil); the distance between the line and the line and the pad is greater than or equal to 0.33mm (13mil) ). In practical applications, increase the distance when conditions permit; When...Read more -

HDI PCB Design Questions

1. Which aspects should the circuit board DEBUG start from? As far as digital circuits are concerned, first determine three things in order: 1) Confirm that all power values meet the design requirements. Some systems with multiple power supplies may require certain specifications for the order ...Read more -

High frequency PCB design probelm

1. How to deal with some theoretical conflicts in actual wiring? Basically, it is right to divide and isolate the analog/digital ground. It should be noted that the signal trace should not cross the moat as much as possible, and the return current path of the power supply and signal should not be...Read more -

High frequency PCB design

1. How to choose PCB board? The choice of PCB board must strike a balance between meeting design requirements and mass production and cost. Design requirements include electrical and mechanical parts. This material problem is usually more important when designing very high-speed PCB boards (frequ...Read more -

What is the difference between gold plating and silver plating on PCB?

Many DIY players will find that the PCB colors used by various board products in the market are dazzling. The more common PCB colors are black, green, blue, yellow, purple, red and brown. Some manufacturers have ingeniously developed PCBs of different colors such as white and pink. In the tradi...Read more