N'ime usoro mmepụta PCB, enwere usoro ọzọ dị mkpa, nke ahụ bụ, ngwa ọrụ. Ndokwa nke usoro nke dị mkpa maka nhazi SMT na-esote.

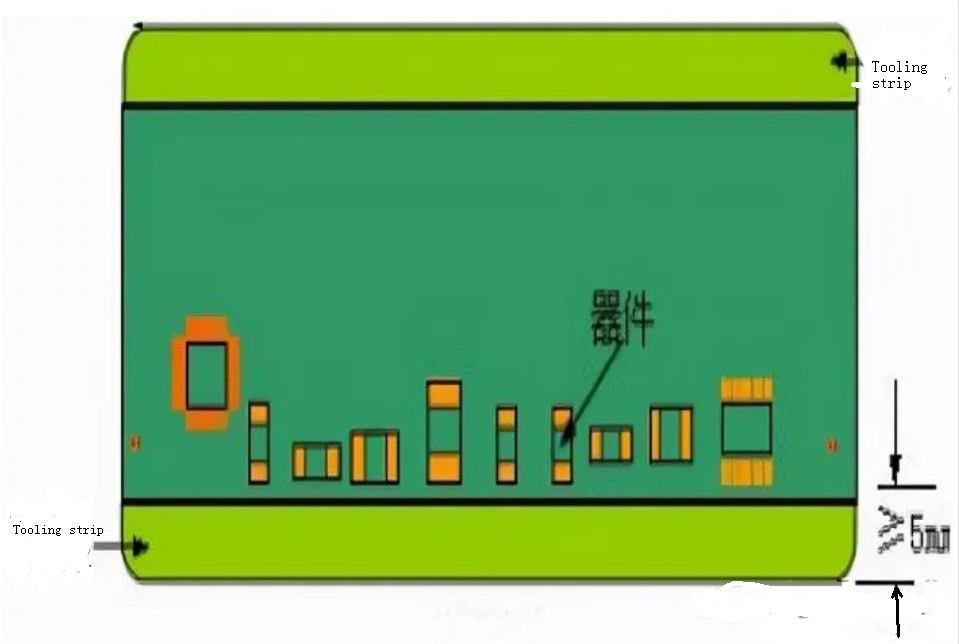

Ngwá ọrụ na-etinye aka na akụkụ abụọ ma ọ bụ akụkụ anọ nke PCB Board iji weld igwe igwe SMT na-agagharị na PCB Board na-aga n'ihu igwe SMT. Ọ bụrụ na ihe mejupụtara ya dị nso na ụzọ egwu na-abanye na igwe SMT igwe SMT igwe ma kenye ha na PCB Board, Plunsuton nwere ike ime. N'ihi ya, a gaghị emepụta ihe nrụpụta, yabụ, a ga-echekwa otu ngwa ngwa ngwa, yana obosara nke 2-5mm. Usoro a dịkwa mma maka ụfọdụ plọg-na-eme ihe, mgbe ebili mmiri na-agbanye na-egbochi ụdị ihe a.

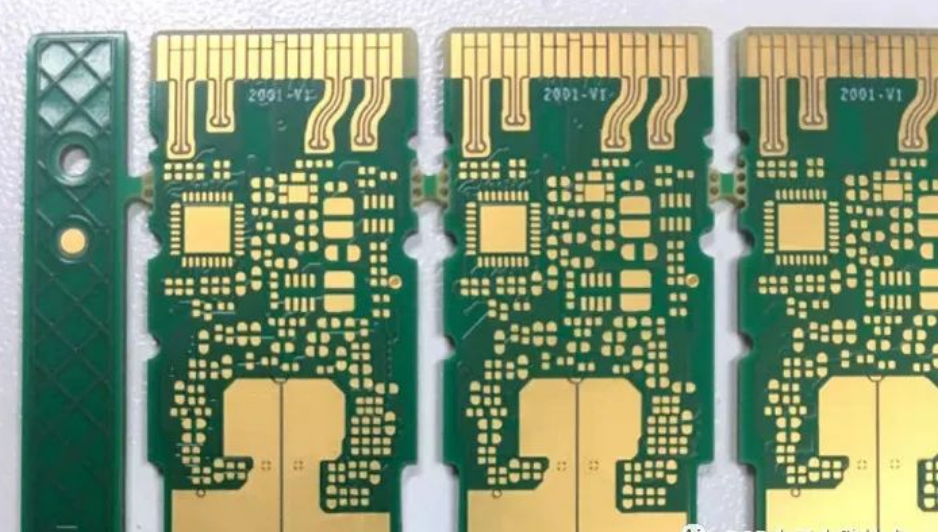

Ngwaọrụ eji arụ ọrụ abụghị akụkụ nke PCB Board na enwere ike wepu ya mgbe emechara PCBA

Ofzọ nkemepụta ngwa ngwa:

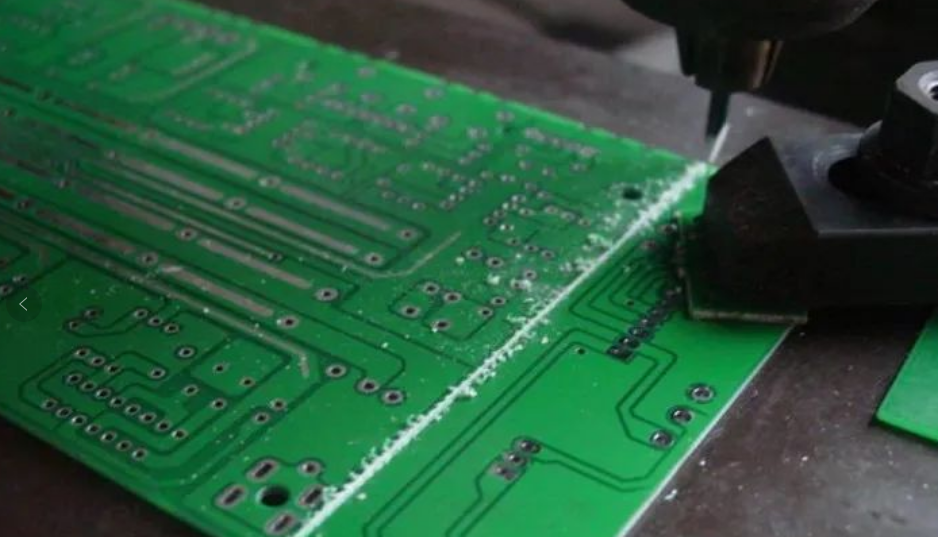

1, V-bee: Njikọ usoro dị n'etiti ngwaọrụ warara na bọọdụ, ntakịrị na akụkụ abụọ nke PCB Board, mana egbula!

2, ijikọ Ogwe: Jiri ọtụtụ ọkpọ iji jikọọ na ngalaba PCB, mee ụfọdụ oghere stampụ n'etiti, nke mere na ejiri aka rụọ ọrụ ma ọ bụ jiri igwe ahụ sachapụ ya.

Ọ bụghị sọks PCB niile kwesịrị ịgbakwunye ngwa ngwa, ma ọ bụrụ na PCB Board na-eme ka patch dị n'ime 5mm n'otu akụkụ nke PCB, ma ọ bụrụhaala na ịgbakwunye ngwa ngwa n'akụkụ nke ọzọ. Ndị a na-adọrọ uche nke PCB.

Ndị na-eji ngwa ngwa gụrụ ọnụ ọgụgụ nke PCB, yabụ ọ dị mkpa idozi akụ na ụba na nchọpụta mgbe ị na-echepụta PCB usoro.

Maka ụfọdụ ụdị PCB Board, ndị PCB Board nwere 2 ma ọ bụ 4 ngwaọrụ iji dị mfe site na iji nwayọ chịkọta bọọdụ ahụ.

Na nhazi SMT, ihe eji eme ihe eji eme ihe kwesiri iji mezuo obosara igwe akara. Maka bọọdụ ahụ nwere obosara karịrị 350mm, ọ dị mkpa iji soro injinia usoro SMT na-ekwurịta okwu.