Dabere na usoro ahụ, a ga-ekewa triccil nke PCB na edemede ndị a:

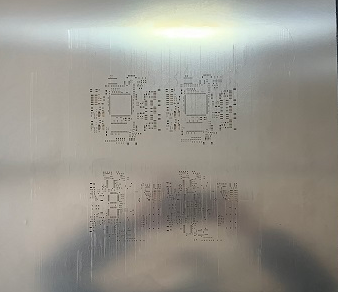

1. Solder Paste Stepil: dị ka aha ahụ na-egosi, a na-eji ya sọlị sọks. Igwefoto oghere na mpempe ígwè nke dabara na pad nke PCB Board. Mgbe ahụ, jiri solder mado gaa na pad bọọdụ pcBB site na stencil. Mgbe ị na-ebido syder, tinye sọver mado n'elu stencil, ma jiri scarde kpuchie ya site na stecil. Tapawa ihe ndị SMD, na ihe na-egosi ọ bụla nwere ike ịme otu n'otu, na ihe nkwụnye ahụ na-agbanye.

2. Jiri na-enye onyinye (ịnye onyinye bụ iji ikuku na-acha uhie uhie na-ezo aka na mkpụrụ osisi na-agagharị site na isi na-acha ọbara ọbara) na-ekwupụta PCB nke PCB site na nchara. Mgbe ahụ akara ihe ndị ahụ, ma mgbe ihe mejupụtara ya na PCB, plọg na plọg na ihe nkwụnye na-aga n'ihu.

3. Stim-Usoro stencil: Mgbe ọ dị mkpa iji solder mado na gluu, mgbe ahụ, a ga-eji stuln. A na-ejikọ stencil abụọ, otu stencil stencil na otu stencil steil gị dị n'otu. Etu esi amata ma ka ijiri stencric ma ọ bụ gluu uhie maka solder mado? Buru ụzọ ịghọta ma ọ bụrụ na ọ ga-ebu ụzọ sọlị ma ọ bụ na-acha ọbara ọbara gluu. Ọ bụrụ na a na-etinye caser pastede na mbụ, mgbe ahụ, a na-eme nke ọma, mgbe ahụ, a na-eme syn paste stencil na stencil dị nkịtị, a na-eme stencil gluu n'ime stencil stencil. Ọ bụrụ na a na-etinye gluu gluu na-acha ọbara ọbara, mgbe ahụ, a na-emegharị gluu gluu n'ime stencil laser nkịtị, na solder paste na stencil stepị.