1. PCB site na oghere oghere

Enwere ọtụtụ ụzọ isi wuo akwa akwa akwa nke na-emezu ihe achọrọ na mgbidi oghere nke mkpụrụ. A na-akpọ nke a ịgbalite mgbidi oghere na ngwa ụlọ ọrụ mmepụta ihe. Ndị na-emepụta bọọdụ PCB ya na-eji ọtụtụ tankị nchekwa etiti dị n'usoro mmepụta. Onye ọ bụla nchekwa tank tank nwere njikwa ya na nhazi ya chọrọ. Site-oghere electroplating bụ ụdi mkpa n'ichepụta usoro nke mwupu usoro. Mgbe ihe a na-egwupụta ihe na-esi na foil ọla kọpa na mkpụrụ dị n'okpuru ebe a na-ekpo ọkụ na-agbaze resin sịntetik nke na-eme ka ọ bụrụ ntọala nke ọtụtụ ihe ndị na-emepụta ihe, resin a wụrụ awụ na ihe ndị ọzọ na-egwupụta ihe A na-edobe ya n'akụkụ oghere ahụ ma kpuchie ya na oghere ahụ ekpughere ọhụrụ. mgbidi na foil ọla kọpa, nke na-emerụ ahụ n'elu elu nke na-esote.

The wụrụ awụ resin ga-ahapụkwa oyi akwa nke na-ekpo ọkụ axis na oghere mgbidi nke mkpụrụ, nke na-egosi adịghị mma adhesion ka ọtụtụ activators, nke na-achọ mmepe nke a klas nke usoro yiri unyi mwepụ na etchback kemịkalụ. Otu ụzọ dabara adaba maka ụdị bọọdụ sekit a na-ebipụta bụ iji ink dị ala na-enweghị viscosity emebere nke ọma iji mepụta mkpuchi nke ukwuu na nke na-eduzi nke ukwuu na mgbidi dị n'ime nke ọ bụla site na oghere. N'ụzọ dị otú a, ọ dịghị mkpa ka a na-eji ọtụtụ usoro ọgwụgwọ kemịkal, naanị otu nzọụkwụ ngwa, na-esote ọgwụgwọ okpomọkụ, nwere ike ịmepụta mkpuchi na-aga n'ihu n'ime mgbidi oghere niile, enwere ike ịgbanye ya ozugbo na-enweghị ọgwụgwọ ọzọ. Ink a bụ ihe dabere na resin nke nwere nrapanye siri ike ma nwee ike jikọta ya n'ụzọ dị mfe na ọtụtụ mgbidi oghere na-ekpocha ọkụ, si otú a na-ewepụ nzọụkwụ nke etch azụ.

2. Reel linkage ụdị nhọrọ plating

Ntụtụ na ntụtụ nke ngwa eletrọnịkị, dị ka njikọ, sekit agbakwunyere, transistor, na bọọdụ FPCB na-agbanwe agbanwe, ka edobere ka ha nweta ezigbo nguzogide kọntaktị na nguzogide corrosion. Usoro electroplating a nwere ike ịbụ akwụkwọ ntuziaka ma ọ bụ akpaka, ọ dịkwa oke ọnụ ịhọrọ ntụtụ ọ bụla n'otu n'otu maka ịkwanye, ya mere, a ga-eji akwa ịgbado ọkụ. Ọtụtụ mgbe, a na-akụ akụkụ abụọ nke foil ígwè ahụ a na-atụgharị na ọkpụrụkpụ achọrọ, na-ehicha ya site na usoro kemịkalụ ma ọ bụ n'ibu, wee họrọ ya dị ka nickel, gold, silver, rhodium, bọtịnụ ma ọ bụ tin-nickel alloy, ọla kọpa-nickel alloy, nickel. -lead alloy, wdg maka na-aga n'ihu plating. N'ime usoro electroplating nke nhọrọ nhọrọ, nke mbụ, a na-ekpuchi akwa mkpuchi ihe nkiri na-eguzogide n'akụkụ nke efere ọla kọpa nke ọla kọpa nke na-adịghị mkpa ka a na-ekpuchi ya, ma ọ bụ naanị akụkụ ọla kọpa ahọpụtara ka a na-agbanye.

3. Mkpịsị aka aka

Ọ dị mkpa ka akwado ọla ahụ na-adịghị ahụkebe na njikọ ihu osisi, kọntaktị na-apụta n'akụkụ osisi ma ọ bụ mkpịsị aka ọla edo iji nye nguzogide kọntaktị dị ala na nguzogide iyi dị elu. Nke a na usoro a na-akpọ plating ahịrị mkpịsị aka ma ọ bụ protruding akụkụ plating. A na-edobe ọla edo na kọntaktsị na-apụta n'akụkụ ọnụ ya na akwa nickel na oyi akwa dị n'ime. Mkpịsị aka ọla edo ma ọ bụ akụkụ na-apụta na nsọtụ bọọdụ na-eji akwụkwọ ntuziaka ma ọ bụ teknụzụ ntinye akpaka. Ka ọ dị ugbu a, etinyere ọla edo na plọg kọntaktị ma ọ bụ mkpịsị aka ọla edo ejiri nne nne na ụzọ kpuchie ya, bọtịnụ Plated kama.

Usoro a bụ nke a:

1. Wepụ ihe mkpuchi ahụ iji wepụ ihe mkpuchi mkpuchi ma ọ bụ tin-edu na kọntaktị ndị na-apụta.

2. Wepu mmiri na-asa mmiri.

3. Ikpochapụ na abrasives.

4. A na-agbanye ọrụ n'ime 10% sulfuric acid.

5. The ọkpụrụkpụ nke nickel plating na protruding kọntaktị bụ 4-5μm.

6. Na-asa ma wepụ mmiri ịnweta mmiri.

7. Ọgwụgwọ nke ngwọta ntinye ọla edo.

8. Gold plating.

9. Nhicha.

10. ihicha.

4. Ahịhịa ahịhịa

Ọ bụ usoro electrodeposition, na ọ bụghị akụkụ niile na-emikpu n'ime electrolyte n'oge usoro electroplating. Na usoro electroplating a, ọ bụ naanị mpaghara nwere oke ka a na-agbanye ọkụ, ọ nweghịkwa mmetụta na ndị ọzọ. Ọtụtụ mgbe, a na-edobe ọla ndị na-adịghị ahụkebe n'akụkụ akụkụ ahọpụtara nke bọọdụ sekit ebipụtara, dị ka mpaghara dị ka njikọ ọnụ osisi. A na-eji ihe mkpuchi ahịhịa eme ihe ugboro ugboro n'ịrụzi bọọdụ sekit mkpofu na ụlọ ahịa mgbakọ elektrọn. Kechie anode pụrụ iche (anode nke na-adịghị arụ ọrụ nke kemịkalụ, dị ka graphite) n'ime ihe na-amịkọrọ mkpụrụ (owu swab) ma jiri ya weta ihe ngwọta plating n'ebe a chọrọ plating.

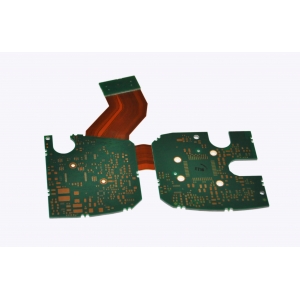

Fastline Circuits Co., Limited bụ ọkachamara: PCB circuit osisi n'ichepụta emeputa, na-enye gị: PCB proofing, ogbe usoro osisi, 1-34 oyi akwa PCB osisi, elu TG osisi, impedance osisi, HDI osisi, Rogers osisi, Nrụpụta na mmepụta nke PCB sekit mbadamba dị iche iche. usoro na ihe dị ka bọọdụ microwave, bọọdụ ugboro redio, bọọdụ radar, bọọdụ foil ọla kọpa siri ike, wdg.