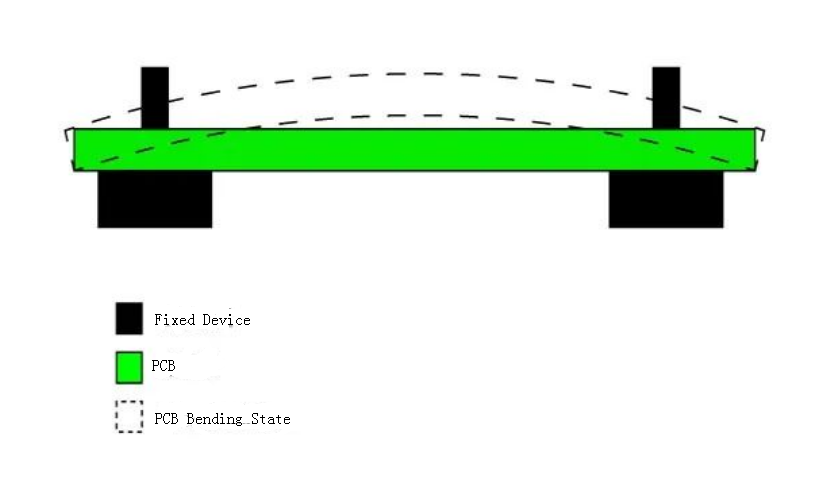

Qhov tseeb, PCB warping kuj hais txog kev khoov ntawm lub rooj tsav xwm hauv Circuit Court, uas yog hais txog lub rooj tsav xwm ncaj nraim. Thaum muab tso rau ntawm lub desktop, ob qhov kawg los yog nruab nrab ntawm lub rooj tsavxwm tshwm me ntsis upward. Qhov tshwm sim no hu ua PCB warping hauv kev lag luam.

Cov mis rau kev xam lub warpage ntawm lub rooj tsavxwm Circuit Court yog nteg lub Circuit Court board tiaj tus ntawm lub rooj nrog plaub fab ntawm lub Circuit Court board nyob rau hauv av thiab ntsuas qhov siab ntawm lub koov nyob rau hauv nruab nrab. Cov mis yog raws li nram no:

Warpage = qhov siab ntawm lub koov / qhov ntev ntawm PCB ntev sab * 100%.

Circuit board warpage tus qauv kev lag luam: Raws li IPC - 6012 (1996 tsab) "Specification for Identification and Performance of Rigid Printed Boards", qhov siab tshaj plaws warpage thiab distortion tso cai rau kev tsim cov Circuit Court boards ntawm 0.75% thiab 1.5%. Vim muaj peev xwm ntawm cov txheej txheem sib txawv ntawm txhua lub Hoobkas, kuj tseem muaj qee qhov sib txawv hauv PCB warpage tswj cov cai. Rau 1.6 board tuab cov pa ob-sided multilayer Circuit Court boards, feem ntau Circuit Court board manufacturers tswj lub PCB warpage ntawm 0.70-0.75%, ntau SMT, BGA boards, yuav tsum nyob rau hauv qhov ntau ntawm 0.5%, ib co Circuit Court board factories nrog muaj zog txheej txheem muaj peev xwm nce. PCB warpage tus qauv rau 0.3%.

Yuav ua li cas kom tsis txhob muaj warping ntawm lub rooj tsavxwm Circuit Court thaum tsim khoom?

(1) Cov txheej txheem kho ib nrab ntawm txhua txheej yuav tsum ua kom sib luag, qhov sib faib ntawm rau cov txheej txheem Circuit Court board, lub thickness ntawm 1-2 thiab 5-6 txheej thiab tus naj npawb ntawm cov khoom ib nrab kho yuav tsum zoo ib yam;

(2) Ntau txheej PCB core board thiab daim ntawv kho yuav tsum siv tib tus neeg muag khoom cov khoom;

(3) Sab nrauv A thiab B sab ntawm kab duab yuav tsum nyob ze li sai tau, thaum A sab yog qhov loj tooj liab, B sab tsuas yog ob peb kab, qhov teeb meem no yooj yim tshwm sim tom qab etching warping.

Yuav ua li cas tiv thaiv Circuit Court board warping?

1.Engineering tsim: interlayer semi-kho daim ntawv npaj yuav tsum tsim nyog; Multilayer core board thiab semi-kho ntawv yuav tsum tau ua los ntawm tib tus neeg muag khoom; Cov duab nraaj ntawm lub dav hlau C/S sab nraud yog ze li sai tau, thiab siv daim phiaj ywj pheej.

2.Drying phaj ua ntej blanking: feem ntau 150 degrees 6-10 teev, tsis suav cov dej vapor nyob rau hauv lub phaj, ntxiv cov resin curing kom tiav, tshem tawm cov kev ntxhov siab nyob rau hauv lub phaj; Daim ntawv ci ua ntej qhib, ob sab hauv txheej thiab ob sab xav tau!

3.Ua ntej laminates, yuav tsum tau them nyiaj mloog mus rau lub warp thiab weft kev taw qhia ntawm solidified phaj: lub warp thiab weft shrinkage piv tsis zoo ib yam, thiab yuav tsum tau them nyiaj mloog kom paub qhov txawv warp thiab weft kev taw qhia ua ntej laminating semi-solidified daim ntawv; Lub phaj tseem ceeb yuav tsum tau them sai sai rau cov kev taw qhia ntawm warp thiab weft; Cov kev taw qhia dav dav ntawm daim ntawv curing yog cov kev taw qhia meridian; Kev taw qhia ntev ntawm tooj liab clad phaj yog meridional; 10 txheej ntawm 4OZ fais fab tuab daim ntawv

4.Lub thickness ntawm lub lamination kom tshem tawm cov kev ntxhov siab tom qab txias nias, trimming raw ntug;

5.Baking phaj ua ntej drilling: 150 degrees rau 4 teev;

6.Nws yog qhov zoo dua kom tsis txhob mus los ntawm kev sib tsoo txhuam, tshuaj ntxuav yog pom zoo; Tshwj xeeb fixture yog siv los tiv thaiv lub phaj ntawm dabtsi yog khoov thiab folding

7.Tom qab txau cov tin rau ntawm lub tiaj tus marble lossis steel phaj ntuj txias rau chav sov lossis huab cua ntab saum txaj txias tom qab ntxuav;