Feem ntau: piv nrog cov txheej txheem ntau lawm ntawm cov txheej txheem ntau txheej thiab cov txheej txheem ob txheej, muaj 2 txheej txheem ntxiv, raws li: sab hauv kab thiab lamination.

Nyob rau hauv kev nthuav dav: nyob rau hauv cov txheej txheem ntau lawm ntawm ob txheej txheej phaj, tom qab txiav tiav, drilling yuav tsum tau nqa tawm, thiab ces mus rau hauv lub tooj liab, kab; Nyob rau hauv cov txheej txheem ntawm cov txheej txheem ntau lawm, tom qab qhib cov khoom tiav, nws yuav tsis raug drilled ncaj qha, tab sis ua ntej nws yuav tsum tau mus rau hauv kab thiab lamination, thiab tom qab ntawd mus rau hauv lub drilling rhiav mus laum, thiab ces. rau hauv tooj liab thiab kab.

Ntawd yog, ntawm qhov qhib thiab qhov drilling, ob txheej txheem ntawm "sab hauv" thiab "lamination" ntxiv. Cov saum toj no yog qhov sib txawv ntawm ntau txheej board thiab ob txheej txheej board ntau lawm.

Tom ntej no, cia peb saib seb ob qhov txheej txheem ntawm cov kab sab hauv thiab lamination ua dab tsi

Sab hauv kab

Cov txheej txheem "kab" hauv kev tsim cov phaj ob txheej, nrog rau cov yeeb yaj kiab compression, raug, kev loj hlob (yog tias koj tsis nco qab, koj tuaj yeem rov qab mus saib nws).

Lub "sab hauv Circuit Court" ntawm no tsis yooj yim li! Ntxiv nrog rau cov zaj duab xis laminated sab hauv, sab hauv raug, sab hauv kev loj hlob, nws kuj suav nrog kev kho ua ntej, sab hauv etching, sab hauv zaj duab xis tshem tawm thiab sab hauv AOI.

Nyob rau hauv cov txheej txheem ntawm ob txheej txheej txheej, lub rooj tsavxwm tom qab cov tooj liab deposition tiav, tsis muaj cov kab ntau lawm, ncaj qha mus rau hauv cov yeeb yaj kiab nias, yog li tsis tas yuav tsum tau ua kev kho mob ua ntej nias ntxiv. Thiab cov ntawv ci tooj liab ntawm no, tsuas yog tuaj ntawm kev cob qhia txiav, qhov saum npoo ntawm lub rooj tsavxwm yuav muaj impurities, yog li

Ua ntej cov zaj duab xis laminate sab hauv, nws yog ib qho tsim nyog yuav tsum tau ua ntej kev kho thiab tu, kev siv tshuaj lom neeg cov tshuaj tiv thaiv, ua ntej tshem cov roj, dej, dej huv, ob lub micro-etching (tshem tawm cov khib nyiab ntawm qhov chaw), thiab tom qab ntawd dej, thiab tom qab ntawd pickling (tom qab ntawd. ntxuav, saum npoo yuav oxidized, yog li nws xav tau pickling), ces dej, ces qhuav, thiab ces mus rau hauv lub puab laminate zaj duab xis.

Sab hauv laminate zaj duab xis ua ntej kev kho mob

Tom qab nias lub rooj tsavxwm, vim nws tsis tau tho, nws zoo nkaus li tiaj tus.

Nias zaj duab xis, raug, kev loj hlob, cov teeb meem tshwj xeeb ntawm cov kev sib txuas, tau qhia nyob rau hauv tsab xov xwm ntawm ob txheej txheej phaj ntau lawm, ntawm no yuav tsis rov ua dua.

Tom qab kev txhim kho tiav lawm, ib feem ntawm cov tooj dag yuav raug nthuav tawm, vim tias txheej txheej txheej txheej txheej txheej txheej txheej txheej txheej txheej txheej txheej txheej txheej txheej txheej txheej txheej txheej txheej txheej txheej txheej txheej txheej txheej txheej ntawm cov yeeb yaj kiab tsis zoo. Yog li ntawd, tom qab txheej txheej txheej txheej txheej tiav tiav, cov kab tooj liab raug tshem tawm yog qhov uas yuav tsum tau khaws cia, thiab cov tooj liab nthuav tawm tom qab txheej txheej txheej sab hauv yog qhov uas yuav tsum tau muab tshem tawm, yog li

Cov txheej txheem etching sab hauv thiab txheej txheej txheej txheej txheej sab nrauv kuj sib txawv, sab hauv etching yog txheej txheem alkaline, thaum lub sij hawm etching, cov zaj duab xis qhuav tseem nyob hauv, qhov tsis muaj zaj duab xis qhuav (tshuaj tooj liab) yog etched ua ntej, thiab ces cov pwm raug tshem tawm.

Lub etching ntawm txheej txheej yog thawj zaug tshem tawm thiab tom qab ntawd etched, thiab cov kab yog ib feem tiv thaiv los ntawm cov kua tin.

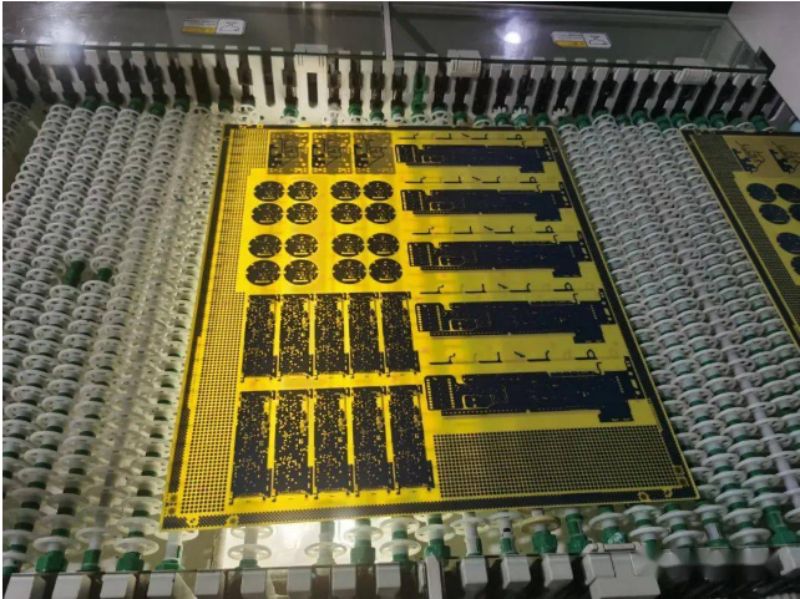

Sab hauv zaj duab xis etching kab, sab laug yog lub luag haujlwm rau etching, txoj cai yog lub luag haujlwm rau kev tshem tawm zaj duab xis.

Tom qab etching lub rooj tsav xwm Circuit Court, cov tooj liab ntau dhau tau raug tshem tawm, thiab qhov seem ntawm cov yeeb yaj kiab qhuav tsis tau muab tshem tawm.

Lub Circuit Court board tom qab stripping.

Tom qab txheej txheej txheej ntawm zaj duab xis tiav, txheej txheej sab hauv ntawm txoj kab tiav tiav, lub sijhawm no, thiab tom qab ntawd AOI kho qhov muag pom, txhawm rau txiav txim siab tias tsis muaj teeb meem, koj tuaj yeem ua tiav cov txheej txheem lamination.

Lamination:

Tsuas yog ua lub rooj tsavxwm, peb hu nws lub rooj tsavxwm sab hauv, yog tias nws yog 4 txheej ntawm lub rooj tsavxwm, yuav muaj 1 lub rooj tsavxwm sab hauv, yog tias nws yog 6 txheej ntawm lub rooj tsavxwm, yuav muaj 2 lub hauv paus tseem ceeb.

Lub hom phiaj tseem ceeb ntawm cov txheej txheem no yog ua kom lub puab phaj phaj thiab txheej txheej txheej sib txuas ua ke los ua ib qho tag nrho. Lub luag haujlwm rau cov khoom sib txuas, hu ua PP, Suav hu ua semi-curing sheet, lub ntsiab muaj pes tsawg leeg yog cob thiab iav fiber ntau, nws tseem yuav ua si lub hauv paus core board thiab txheej tooj liab ntawv nyiaj rwb thaiv tsev lub hom phiaj.

Txhawm rau kom ntseeg tau qhov zoo ntawm ntau txheej pawg thawj coj saib, PP tus muag khoom ntawm Jialichuang tseem yog South Asia Electronics.

Feem ntau, cov txheej txheem lamination tau muab faib ua plaub theem hauv kev txiav txim: Browning, pre-stacking, platen, thiab nias. Tom ntej no, cia saib cov ntsiab lus ntawm txhua tus txheej txheem sib cais.Lub phaj core phaj tom qab kev tshem tawm zaj duab xis tiav yog browned ua ntej. Lub rooj tsav xwm browned yuav ntxiv ib txheej ntawm cov zaj duab xis browned rau ntawm qhov chaw ntawm lub rooj tsav xwm Circuit Court, uas yog xim av metallized, thiab nws qhov chaw tsis sib xws, txhawm rau ua kom yooj yim rau kev sib txuas nrog PP.

Lub hauv paus ntsiab lus zoo ib yam li thaum kho lub log tsheb kauj vab, qhov chaw tawg yuav tsum tau muab cov ntaub ntawv los txhim kho cov nplaum nplaum.

Cov txheej txheem Browning kuj yog cov txheej txheem tshuaj lom neeg, uas yuav dhau los ntawm kev ntxuav, alkali ntxuav, ntau txoj kev ntxuav, ziab, txias thiab lwm yam txheej txheem.

ua ntej

Cov txheej txheem ua ntej stacking, ua nyob rau hauv lub rhiav tsis muaj plua plav, yuav muab cov tub ntxhais phaj thiab PP ua ke. Ib qho PP yog muab tso rau ntawm txhua sab ntawm lub phaj tseem ceeb. Qhov ntev thiab qhov dav ntawm PP yuav yog 2 hli loj dua cov tub ntxhais phaj kom tiv thaiv hollow npoo tom qab nias.

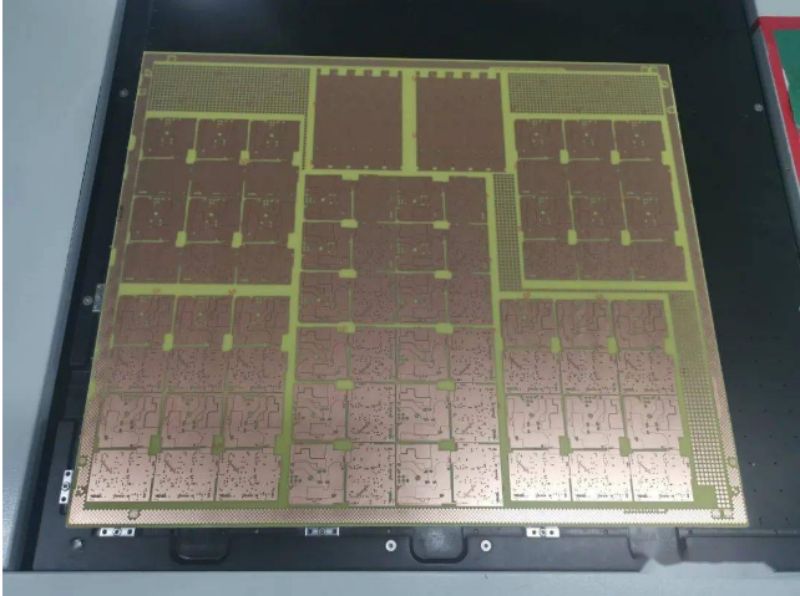

Raft:

Lub hom phiaj tseem ceeb ntawm kab phaj yog ntxiv ib txheej ntawm tooj liab ntawv ci saum PP txheej los npaj rau cov kab tom ntej. Tsis tas li ntawd, steel phaj thiab kraft ntawv yuav muab ntxiv rau cov txheej txheej sab nraud

Thawj ob peb kauj ruam yog los npaj rau qhov kawg lamination.

Ua ntej laminating, thiaj li yuav tiv thaiv warping, yuav muaj ib tug cover phaj, txog 12 hli tuab, hlau.

Laminating muaj xws li ob txheej txheem ntawm kub nias thiab txias nias, feem nyob rau hauv kub xovxwm thiab txias xovxwm. Qhov no yog qhov txuas tseem ceeb heev, los txiav txim siab txog yam xws li lub tshuab nqus tsev, qhov kub thiab txias, siab, lub sijhawm, cov yam ntxwv no sib koom ua ke, txhawm rau tsim cov khoom siv hluav taws xob zoo.

Piv txwv li, nyob rau hauv ib lub sij hawm ntawm lub sij hawm, qhov kub thiab txias npaum li cas, lub siab npaum li cas, thiab lub sij hawm ntev yuav tsum tau kho kom meej.

Tom qab qhov kawg ntawm cov txheej txheem no, PP thiab cov tub ntxhais phaj sab hauv thiab cov ntawv ci tooj liab sab nrauv yuav raug sib txuas ua ke.

Tom qab tawm ntawm cov xovxwm, qhov tsis siv neeg dismantling yog nqa tawm, lub phaj hlau raug tshem tawm, thiab nws raug xa mus rau chav platoon dua tom qab sib tsoo. Raws li pom nyob rau hauv daim duab 11, lub tshuab yog tshem tawm cov hlau phaj.

Lub laminated multi-layer circuit board yuav raug xa rov qab mus rau nws qhov qub drilling rhiav mus laum, thiab cov txheej txheem seem yog tib yam li cov txheej txheem tsim khoom ntawm ob txheej txheej.