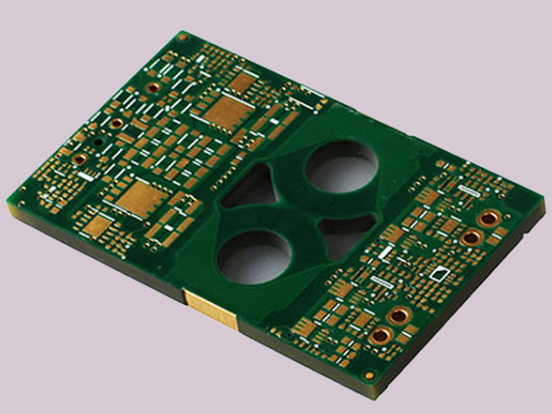

Taw qhia ntawmThick Copper Circuit BoardTechnology

(1) Kev npaj ua ntej plating thiab kev kho electroplating

Lub hom phiaj tseem ceeb ntawm thickening tooj liab plating yog los xyuas kom meej tias muaj ib tug tuab txaus tooj liab plating txheej nyob rau hauv lub qhov los xyuas kom meej tias tus nqi kuj nyob rau hauv ntau yam uas yuav tsum tau los ntawm tus txheej txheem. Raws li lub plug-in, nws yog los kho txoj hauj lwm thiab xyuas kom meej lub zog ntawm kev sib txuas; raws li cov khoom siv saum npoo av, qee qhov tsuas yog siv los ntawm lub qhov, uas ua lub luag haujlwm ntawm kev ua hluav taws xob ntawm ob sab.

(2) Cov khoom kuaj xyuas

1. Feem ntau xyuas cov metallization zoo ntawm lub qhov, thiab xyuas kom meej tias tsis muaj ntau tshaj, burr, dub qhov, qhov, thiab lwm yam nyob rau hauv lub qhov;

2. Tshawb xyuas seb puas muaj av thiab lwm yam ntau dhau ntawm qhov chaw ntawm lub substrate;

3. Tshawb xyuas tus lej, kos duab, cov ntaub ntawv txheej txheem thiab txheej txheem piav qhia ntawm substrate;

4. Tshawb nrhiav txoj haujlwm mounting, mounting yuav tsum tau thiab cov txheej txheej uas lub plating tank yuav dais;

5. Lub plating cheeb tsam thiab cov txheej txheem tsis yuav tsum tau meej los xyuas kom meej qhov ruaj khov thiab muaj peev xwm ntawm cov txheej txheem electroplating tsis;

6. Kev ntxuav thiab npaj cov khoom siv hluav taws xob, kev kho hluav taws xob ua ntej ua kom cov tshuaj muaj zog;

7. Txiav txim siab seb cov dej da dej puas tsim nyog thiab qhov chaw ntawm lub phaj electrode; Yog hais tias lub spherical anode raug ntsia rau hauv kem, kev noj yuav tsum tau kuaj xyuas;

8. Tshawb xyuas qhov ruaj khov ntawm qhov chaw sib cuag thiab qhov sib txawv ntawm qhov voltage thiab tam sim no.

(3) Kev tswj xyuas zoo ntawm cov tuab tooj liab plating

1. Ua tib zoo xam qhov chaw plating thiab xa mus rau qhov cuam tshuam ntawm cov txheej txheem tsim khoom tiag tiag ntawm qhov tam sim no, txiav txim siab qhov tsim nyog tus nqi ntawm qhov tam sim no, tswj qhov kev hloov ntawm tam sim no hauv cov txheej txheem electroplating, thiab xyuas kom muaj kev ruaj ntseg ntawm cov txheej txheem electroplating. ;

2. Ua ntej electroplating, thawj zaug siv lub rooj tsavxwm debugging rau kev sim plating, kom lub da dej yog nyob rau hauv lub active lub xeev;

3. Txiav txim siab qhov ntws ntawm tag nrho cov tam sim no, thiab tom qab ntawd txiav txim siab qhov kev txiav txim ntawm cov ntawv dai. Nyob rau hauv txoj cai, nws yuav tsum tau siv los ntawm deb mus rau ze; los xyuas kom meej lub uniformity ntawm tam sim no tis ntawm txhua qhov chaw;

4. Los xyuas kom meej lub uniformity ntawm txheej nyob rau hauv lub qhov thiab qhov sib xws ntawm lub thickness ntawm txheej, ntxiv rau cov txheej txheem kev ntsuas ntawm stirring thiab filtering, nws tseem yuav tsum tau siv impulse tam sim no;

5. Tsis tu ncua saib xyuas cov kev hloov ntawm tam sim no thaum lub sij hawm electroplating txheej txheem los xyuas kom meej qhov kev cia siab thiab stability ntawm tus nqi tam sim no;

6. Tshawb xyuas seb lub thickness ntawm tooj liab plating txheej ntawm lub qhov ua tau raws li cov kev cai.

(4) Copper plating txheej txheem

Nyob rau hauv tus txheej txheem ntawm thickening tooj liab plating, cov txheej txheem tsis yuav tsum tau saib xyuas tsis tu ncua, thiab tsis tsim nyog poob yog feem ntau tshwm sim los ntawm subjective thiab lub hom phiaj yog vim li cas. Txhawm rau ua txoj haujlwm zoo ntawm thickening txheej txheem tooj liab, cov hauv qab no yuav tsum tau ua:

1. Raws li cheeb tsam tus nqi xam los ntawm lub khoos phis tawj, ua ke nrog cov kev paub tas li sau nyob rau hauv qhov tseeb ntau lawm, nce ib qho nqi;

2. Raws li tus nqi tam sim no suav, txhawm rau kom ntseeg tau tias cov txheej txheem plating nyob rau hauv lub qhov, nws yog ib qho tsim nyog yuav tsum tau nce ib qho nqi, uas yog, qhov inrush tam sim no, ntawm tus nqi qub tam sim no, thiab tom qab ntawd rov qab mus rau qhov chaw. tus nqi qub hauv lub sijhawm luv luv;

3. Thaum lub electroplating ntawm lub Circuit Court board ncav cuag 5 feeb, tshem tawm lub substrate los soj ntsuam seb cov tooj liab txheej ntawm qhov chaw thiab lub puab phab ntsa ntawm lub qhov yog tiav, thiab nws yog zoo dua hais tias tag nrho cov qhov muaj ib tug metallic luster;

4. Ib qho kev ncua deb yuav tsum tau khaws cia ntawm lub substrate thiab lub substrate;

5. Thaum lub thickened tooj liab plating mus txog qhov yuav tsum tau electroplating lub sij hawm, ib tug tej yam nqi ntawm tam sim no yuav tsum tau khaws cia thaum lub sij hawm tshem tawm ntawm lub substrate los xyuas kom meej tias cov nto thiab qhov ntawm lub substrate tom ntej yuav tsis dub los yog darkened.

Cov kev ceev faj:

1. Tshawb xyuas cov ntaub ntawv txheej txheem, nyeem cov txheej txheem uas yuav tsum tau ua thiab paub txog cov txheej txheem machining ntawm substrate;

2. Tshawb xyuas qhov chaw ntawm lub substrate rau khawb, indentations, raug tooj liab qhov chaw, thiab lwm yam .;

3. Ua tiav kev sim ua raws li cov khoom siv ua haujlwm floppy disk, ua ntej kev tshuaj xyuas ua ntej, thiab tom qab ntawd ua tiav tag nrho cov haujlwm ua haujlwm tom qab ua tiav cov txheej txheem thev naus laus zis;

4. Npaj cov cuab yeej ntsuas thiab lwm yam cuab yeej siv los saib xyuas qhov ntev geometric ntawm lub substrate;

5. Raws li cov khoom siv raw ntawm cov txheej txheem ua haujlwm, xaiv cov cuab yeej milling tsim nyog (milling cutter).

(5) Kev tswj kom zoo

1. Ua tib zoo siv thawj kab lus tshuaj xyuas kom ntseeg tau tias cov khoom loj raws li cov qauv tsim;

2. Raws li cov ntaub ntawv raw ntawm lub rooj tsavxwm Circuit Court, tsim nyog xaiv cov txheej txheem milling tsis;

3. Thaum kho txoj hauj lwm ntawm lub rooj tsavxwm Circuit Court, ua tib zoo clamp nws kom tsis txhob muaj kev puas tsuaj rau cov txheej txheem solder thiab solder daim npog qhov ncauj ntawm qhov chaw ntawm lub rooj tsavxwm;

4. Txhawm rau kom ntseeg tau tias qhov sib xws ntawm qhov ntev ntawm lub substrate, qhov tseeb ntawm qhov chaw yuav tsum tau tswj nruj me ntsis;

5. Thaum disassembling thiab assembling, yuav tsum tau them tshwj xeeb mloog mus rau padding lub hauv paus txheej ntawm lub substrate kom tsis txhob muaj kev puas tsuaj rau txheej txheej nyob rau saum npoo ntawm lub Circuit Court board.