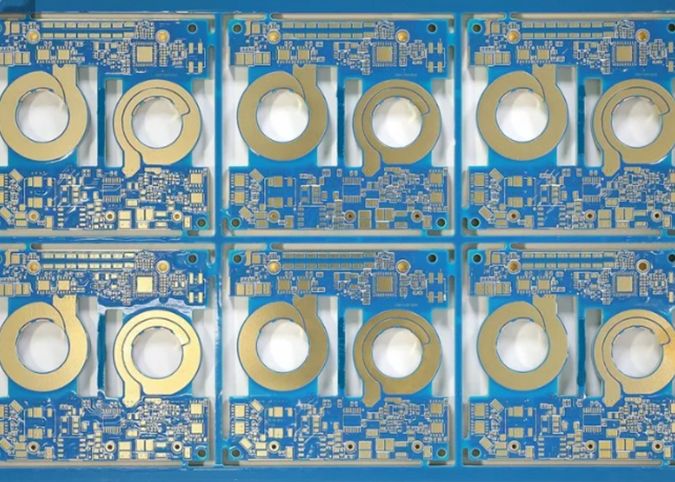

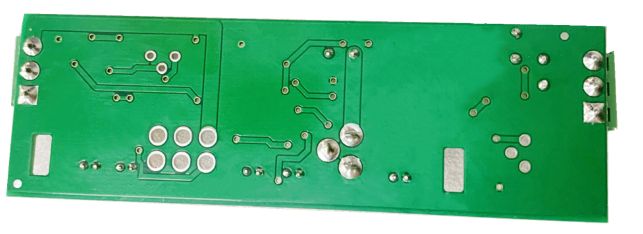

Cov ntaub ntawv Circuit Court cia siab rau cov khoom siv hluav taws xob zoo thiab cov khoom siv hluav taws xob los txuas cov khoom siv niaj hnub no rau ib leeg rau kev ua haujlwm zoo. Txawm li cas los xij, raws li cov neeg siv khoom, cov PCB tooj liab conductors, txawm tias DC lossis mm Wave PCB boards, xav tau kev tiv thaiv kev laus thiab kev tiv thaiv oxidation. Qhov kev tiv thaiv no tuaj yeem ua tiav hauv daim ntawv ntawm electrolysis thiab immersion txheej. Lawv feem ntau muab qhov sib txawv ntawm qhov muaj peev xwm weld, yog li txawm tias muaj qhov me me, micro-surface mount (SMT), thiab lwm yam, tuaj yeem tsim qhov chaw vuam zoo heev. Muaj ntau yam txheej txheej thiab kev kho deg uas tuaj yeem siv rau ntawm PCB tooj liab conductors hauv kev lag luam. Kev nkag siab txog cov yam ntxwv thiab cov nqi txheeb ze ntawm txhua txheej txheej thiab kev kho saum npoo yuav pab peb xaiv qhov tsim nyog kom ua tiav qhov kev ua tau zoo tshaj plaws thiab kev pab cuam lub neej ntev tshaj plaws ntawm PCB boards.

Kev xaiv ntawm PCB qhov kawg ua tiav tsis yog txheej txheem yooj yim uas yuav tsum tau xav txog PCB lub hom phiaj thiab kev ua haujlwm. Cov qauv tam sim no mus rau densely tau ntim, cov suab nrov, qib siab-nrawm pcb circuits thiab me, high-zaus pcbs pooj ib qho kev sib tw rau ntau tus pcb tuam ntxhab. PCB circuits yog tsim los ntawm laminates ntawm ntau yam tooj liab foil luj thiab thicknesses muab rau PCB manufacturers los ntawm cov khoom manufacturers, xws li Rogers, uas tom qab ntawd ua cov laminates rau hauv ntau hom PCBS rau siv hauv electronics. Yog tias tsis muaj qee yam kev tiv thaiv saum npoo, cov conductors ntawm lub voj voog yuav oxidize thaum khaws cia. Tus neeg xyuas pib kho qhov chaw ua raws li kev thaiv kev cais tus neeg xyuas pib ntawm ib puag ncig. Nws tsis tsuas yog tiv thaiv PCB tus neeg xyuas pib los ntawm oxidation, tab sis kuj muab kev sib txuas rau vuam circuits thiab cov khoom siv, nrog rau kev sib txuas ua ke ntawm kev sib koom ua ke (ics).

Xaiv qhov tsim nyog PCB nto

Kev kho qhov chaw tsim nyog yuav tsum pab ua kom tau raws li daim ntawv thov PCB thiab cov txheej txheem tsim khoom. Tus nqi sib txawv vim cov khoom siv sib txawv, cov txheej txheem sib txawv thiab hom kev ua tiav yuav tsum tau ua. Qee qhov kev kho mob saum npoo tso cai rau kev ntseeg siab thiab kev sib cais siab ntawm cov kab hluav taws xob sib txuas, thaum lwm tus tuaj yeem tsim cov txuas tsis tsim nyog ntawm cov neeg siv khoom. Qee qhov kev kho mob saum npoo ua tau raws li kev ua tub rog thiab aerospace, xws li qhov kub thiab txias, kev poob siab thiab kev vibration, thaum lwm tus tsis tau lees tias qhov kev ntseeg siab xav tau rau cov ntawv thov no. Cov npe hauv qab no yog qee qhov kev kho mob ntawm PCB uas tuaj yeem siv rau hauv circuits xws li DC circuits mus rau millimeter-wave bands thiab high speed digital (HSD) circuits:

●ENIG

●ENEPIG

● HASL

●Immersion Nyiaj

●Immersion Tin

● LF HASL

● OSP

●Electrolytic tawv kub

●Electrolytic bonded kub muag

1. ENIG

ENIG, tseem hu ua cov txheej txheem tshuaj nickel-kub, yog siv dav hauv kev kho deg ntawm PCB board conductors. Qhov no yog ib qho yooj yim cov txheej txheem uas tsis tshua muaj nqi uas tsim ib txheej nyias ntawm weldable kub nyob rau sab saum toj ntawm ib tug npib tsib xee txheej ntawm ib tug neeg xyuas pib, uas ua rau ib tug tiaj tus nto nrog zoo weld muaj peev xwm txawm nyob rau hauv densely packed circuits. Txawm hais tias ENIG txheej txheem ua kom muaj kev ncaj ncees ntawm lub qhov electroplating (PTH), nws kuj ua rau cov neeg xyuas pib poob ntawm qhov ntau zaus. Cov txheej txheem no muaj lub neej ntev cia, raws li RoHS cov qauv, los ntawm cov chaw tsim khoom siv hluav taws xob, mus rau cov txheej txheem kev sib dhos, nrog rau cov khoom kawg, nws tuaj yeem muab kev tiv thaiv mus ntev rau PCB conductors, yog li ntau tus neeg tsim khoom PCB xaiv ib qho kev kho saum npoo.

2. ENEPIG

ENEPIG yog ib qho kev hloov kho ntawm ENIG txheej txheem los ntawm kev ntxiv ib txheej palladium nyias ntawm cov tshuaj npib tsib xee txheej thiab txheej kub plating. Cov txheej palladium tiv thaiv cov nickel txheej (uas tiv thaiv tus neeg xyuas pib tooj liab), thaum cov txheej kub tiv thaiv palladium thiab npib tsib xee. Qhov kev kho saum npoo no yog qhov zoo tagnrho rau kev sib txuas cov khoom siv rau PCB ua thiab tuaj yeem ua ntau yam txheej txheem rov qab. Zoo li ENIG, ENEPIG yog RoHS raws.

3.Ib tug nyiaj

Chemical silver sedimentation kuj yog cov txheej txheem uas tsis yog-electrolytic uas PCB tau muab tso rau hauv ib qho kev daws ntawm cov nyiaj ions los khi cov nyiaj rau saum npoo ntawm tooj liab. Cov txheej txheej ua tau zoo sib xws thiab zoo ib yam li ENIG, tab sis tsis muaj kev tiv thaiv thiab ua haujlwm tau los ntawm cov txheej npib tsib xee hauv ENIG. Txawm hais tias nws cov txheej txheem kho saum npoo yog yooj yim dua thiab muaj txiaj ntsig zoo dua li ENIG, nws tsis haum rau kev cia ntev nrog cov tuam txhab hluav taws xob.

4. Immersion Tin

Cov txheej txheem tshuaj tin deposition tsim cov txheej txheej nyias nyias ntawm tus neeg xyuas pib los ntawm cov txheej txheem ntau kauj ruam uas suav nrog kev ntxuav, micro-etching, acid tov prepreg, immersion ntawm non-electrolytic tin leaching tov, thiab zaum kawg tu. Kev kho Tin tuaj yeem muab kev tiv thaiv zoo rau tooj liab thiab cov neeg siv hluav taws xob, ua rau kev poob qis ntawm HSD circuits. Hmoov tsis zoo, chemically sunk tin tsis yog ib qho ntawm cov khoom siv hluav taws xob ntev tshaj plaws hauv kev kho mob vim tias cov nyhuv tin muaj rau tooj liab dhau sijhawm (piv txwv li, qhov sib txawv ntawm ib qho hlau mus rau lwm qhov txo qhov kev ua haujlwm ntev ntawm tus neeg xyuas pib Circuit Court). Zoo li cov nyiaj siv tshuaj, cov tshuaj tin yog cov hmoov lead-dawb, RoHs-raws li txheej txheem.

5. OSP

Organic welding tiv thaiv zaj duab xis (OSP) yog cov tshuaj tiv thaiv uas tsis yog xim hlau uas yog coated nrog cov kua dej. Qhov kev ua tiav no kuj tseem ua raws RoHS. Txawm li cas los xij, qhov kev kho saum npoo no tsis muaj lub neej ntev ntev thiab siv tau zoo tshaj plaws ua ntej lub voj voog thiab cov khoom sib txuas rau PCB. Tsis ntev los no, OSP membranes tshiab tau tshwm sim hauv kev ua lag luam, uas ntseeg tau tias muaj peev xwm muab kev tiv thaiv mus ntev rau cov neeg siv khoom.

6.Electrolytic nyuaj kub

Kev kho kub kub yog cov txheej txheem electrolytic raws li txheej txheem RoHS, uas tuaj yeem tiv thaiv PCB thiab tooj liab tus neeg xyuas pib los ntawm oxidation ntev. Txawm li cas los xij, vim yog cov khoom siv kim heev, nws kuj yog ib qho ntawm cov khoom siv kim tshaj plaws. Nws kuj muaj qhov tsis zoo weldability, tsis zoo weldability rau kev sib khi mos kub kho, thiab nws yog RoHS raws thiab tuaj yeem muab qhov chaw zoo rau cov cuab yeej sib txuas rau PCB cov thawj coj.