Cov hluav taws xob kev nyab xeeb feem ntau nyob ntawm qib ntawm phaj-ua Hoobkas, uas feem ntau 0.15mm. Qhov tseeb, nws tuaj yeem ze dua. Yog tias lub Circuit Court tsis muaj feem xyuam rau lub teeb liab, tsuav yog tsis muaj luv luv hluav taws xob thiab qhov tam sim no yog qhov tam sim no yuav tsum tau muaj xaim hluav taws xob thiab txuas.

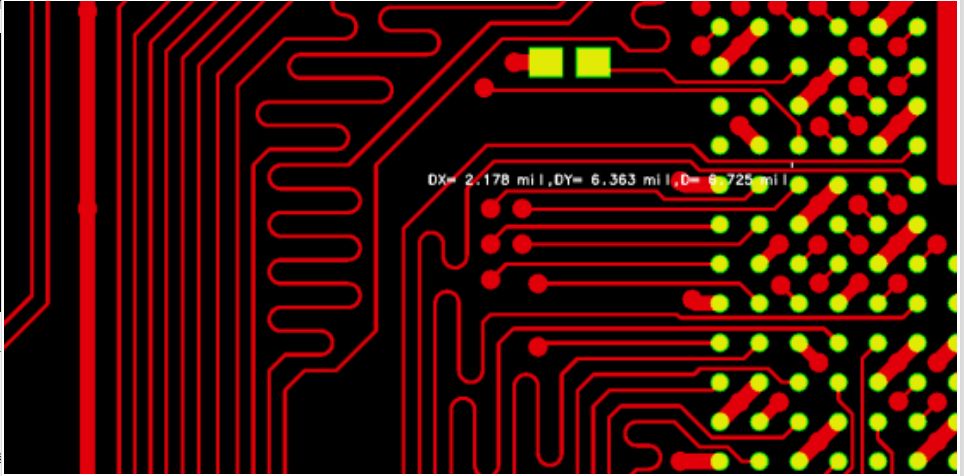

1.Distance ntawm cov xov hlau

Qhov kev ncua deb ntawm cov thawj coj yuav tsum raug txiav txim siab raws li PCB chaw tsim tshuaj paus kev muaj peev xwm. Nws raug nquahu tias qhov kev ncua deb ntawm tus cwj pwm yog yam tsawg 4mil. Txawm li cas los xij, qee cov teeb meem tseem tuaj yeem tsim nrog 3/3mil kab dav thiab kab kab sib tw. Los ntawm cov kev pom ntawm kev tsim khoom, tau kawg, qhov loj dua nyob rau hauv cov xwm txheej. Ib txwm 6mil yog cov pa ntxiv.

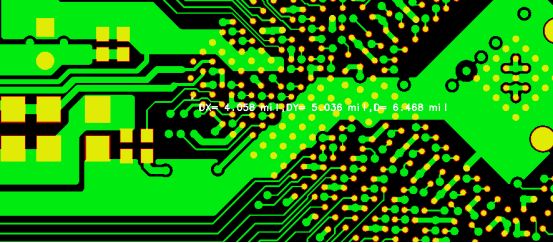

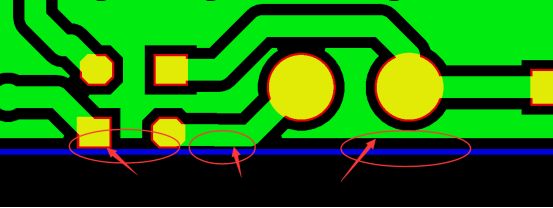

2.Spacing ntawm ncoo thiab hlau

Qhov kev ncua deb ntawm cov ntaub qhwv thiab kab feem ntau tsis tsawg tshaj 4mil, thiab ntau dua qhov kev ncua deb ntawm cov ntaub thiab kab thaum muaj chaw, qhov zoo dua. Vim tias lub vuam vuam yuav tsum muaj lub qhov rais qhib, lub qhov rais qhib tau loj dua 2mil ntawm ncoo. Yog tias qhov sib nrug tsis txaus, nws yuav tsis tsuas yog ua rau cov kab luv ntawm kab txheej, tab sis kuj ua rau tooj liab kis ntawm kab.

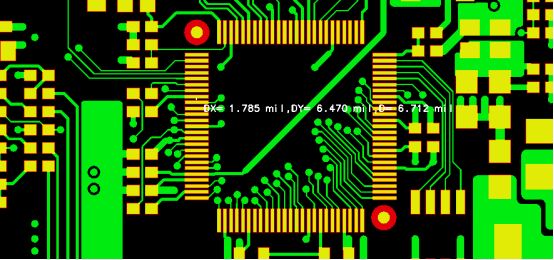

3.Qhov tso ntawm ncoo thiab ncoo

Qhov sib nrug ntawm ntawm ncoo thiab lub ncoo yuav tsum muaj ntau dua 6mil. Nws yog qhov nyuaj ua kom muaj kev sib tw nres-vuam choj nrog cov ntaub qhwv tsis txaus Qhov kev ncua deb ntawm lub network pad thiab ncoo yog me me, thiab nws tsis yooj yim rau cov disassemble cov kev kho tom qab lub tin tau txuas rau ntawm lub vuam.

4.Cov khoom thiab tooj liab, hlau, ncoo plhuav

Qhov kev ncua deb ntawm cov tawv nqaij tooj liab thiab kab thiab cov ntawv nyob nruab nrab ntawm lwm kab cov tawv nqaij thiab kab thiab ntaub ntau dua 8mil los pab txhawb kev tsim khoom thiab kev tsim khoom. Vim tias qhov loj me ntawm cov tawv nqaij tooj liab tsis tas yuav ua ntau tus nqi, me ntsis loj dua thiab me me tsis muaj teeb meem. Txhawm rau txhim kho cov txiaj ntsig ntau lawm los ntawm cov khoom lag luam, cov kab sib nrug ntawm txoj kab thiab cov ntaub qhwv los ntawm daim tawv nqaij tooj liab yuav tsum yog qhov loj.

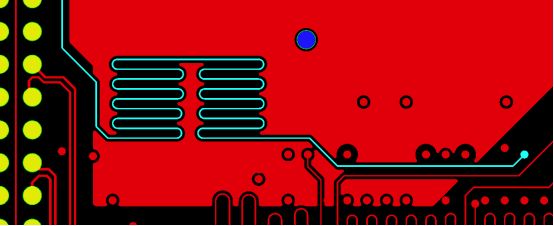

5. Cov xaim xaim xaim xaim xaim, ncoo, tooj thiab phaj phaj ntug

Feem ntau, qhov kev ncua deb ntawm xaim, ncoo thiab cov kab tooj liab yuav tsum muaj ntau dua 10mil, thiab tsawg dua 8mil, thiab tsawg dua 8mil yuav ua rau tooj liab tom qab kev tsim khoom thiab moulding. Yog tias ntug ntawm lub phaj yog V-txiav, ces qhov kev sib tw yuav tsum loj dua 16mil. Hlau thiab ntaub qhwv tsis tsuas yog tooj liab thiaj li yooj yim heev rau ntawm ntug ntawm lub phaj yuav me, tso rau hauv vuam tam sim no, ua rau muaj kev phem vuam, "