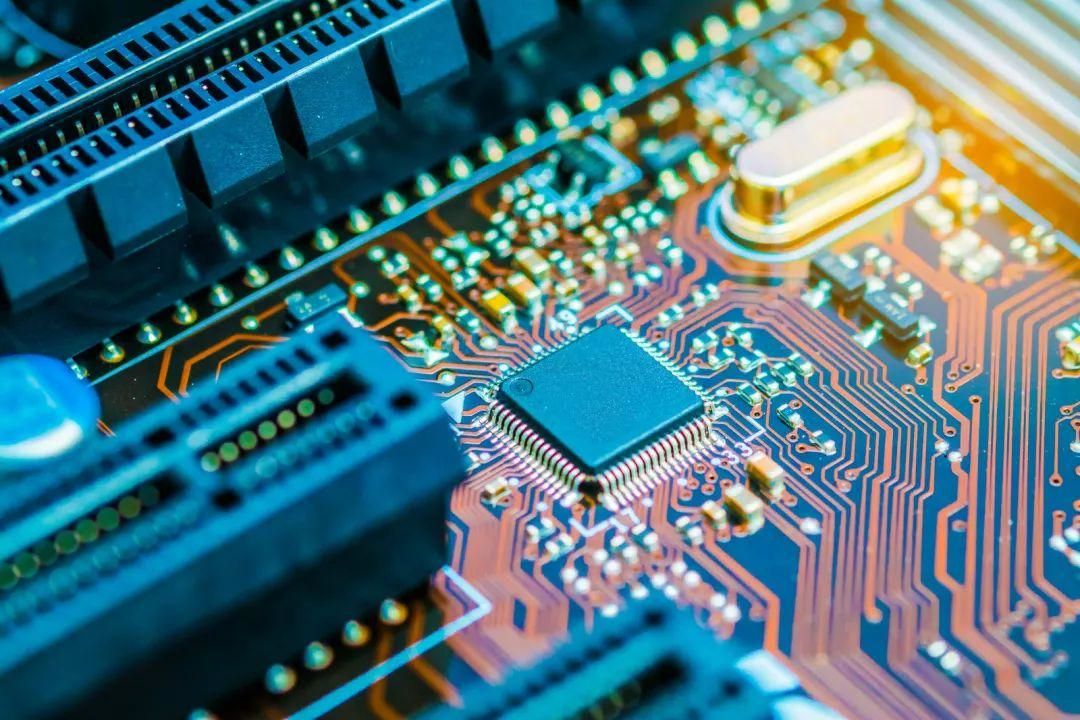

PCB Circuit Coffic Board nyob rau hauv cov txheej txheem ntau lawm, feem ntau ntsib qee cov txheej txheem tsis xws luag, xws li pcb Circuit Cock tawm tsis zoo (kuj feem ntau hais kom muab tooj liab), cuam tshuam cov khoom lag luam zoo. Cov laj thawj rau PCB Circuit Coffe Pov tus tooj liab muaj raws li hauv qab no:

PCB Circuit Court pawg txheej txheem

1, tooj liab cov ntawv ci etching yog ntau dhau, electrolytic tooj liab tooj liab) thiab 18UM

2. Kev sib tsoo hauv zos tshwm sim hauv pcb cov txheej txheem, thiab lub tooj hlau tooj liab tau sib cais los ntawm cov txheej txheem ntawm cov txheej txheem sab nraud. Qhov kev tsis zoo no tshwm sim ua qhov tsis zoo lossis kev qhia txog tooj liab yuav muaj kev cuam tshuam zoo nkauj, lossis hauv tib qho kos / cuam tshuam cim. Tev tawm ntawm qhov tsis zoo ntawm lub tooj hlau tooj liab kom pom cov xim tooj liab, koj tuaj yeem pom cov xim tooj liab, tooj yuav tsis muaj lub zog phem, tooj liab ntawv yog qhov qub.

3, PCB Circuit Tsim Qauv tsis tsim nyog, nrog tuab tooj liab ntawv ci tsim ntawm cov kab nyias nyias, tseem yuav ua rau cov kab thiab tooj ntau dhau thiab tooj.

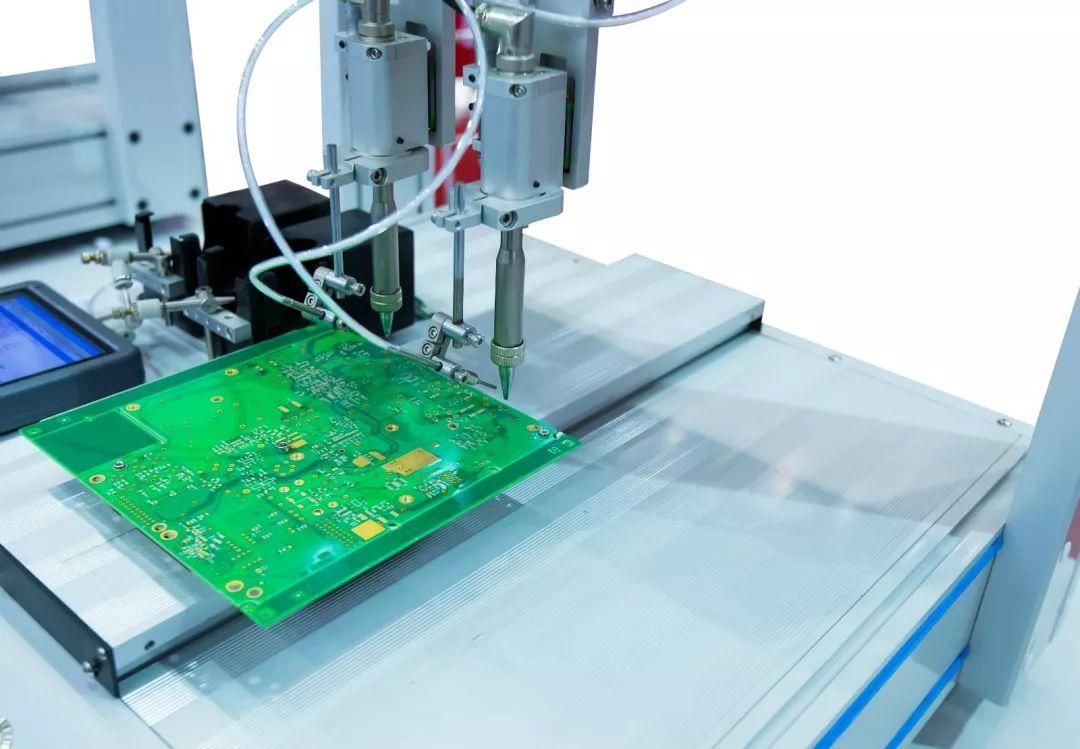

Laminate txheej txheem vim li cas

Nyob rau hauv ib txwm muaj xwm txheej, tsuav yog cov kub nias ntu ntawm laminate ntau dua 30 feeb yog yog li nias Txawm li cas los xij, nyob rau hauv tus txheej txheem ntawm laminate stacking thiab stacking, yog tias tus luam ntawv tooj liab, tab sis tus luam tawm tooj liab dawb ntawm tooj liab lub zog yuav nyob ze ntawm cov kab sib txuas yuav tsis muaj kev txawv txav.

Laminate raw khoom siv

1, zoo tib yam electrolytic tooj liab ntawv ci yog cov khoom siv loj, yog tias cov xov tooj liab, yog tias lub xov tooj liab loj, yog tias lub tshuab hluav taws xob tsis zoo, yog tias lub xov tooj liab loj, yog tias lub tshuab raj tooj liab yuav poob tawm ntawm kev cuam tshuam sab nraud. Qhov no phem ntawm kev tawm tsam tooj liab tooj liab tooj liab cell (uas yog, hu rau saum npoo hlau, tab sis tag nrho cov npoo ntawm tooj liab, tab sis tag nrho cov npoo ntawm tooj liab, tab sis tag nrho cov npoo ntawm tooj liab, tab sis tag nrho cov npoo ntawm tooj liab, tab sis tag nrho cov npoo ntawm tooj liab, tab sis tag nrho cov npoo ntawm tooj liab, tab sis tag nrho cov npoo ntawm tooj liab, tab sis tag nrho cov npoo ntawm tooj liab, tab sis tag nrho cov npoo ntawm tooj los yog qhov tsis zoo.

2. Tsis zoo adaper ntawv ci thiab cob: ib co laminating degrees, xws li HTG Sheet qauv thaum kho tooj liab tooj liab ntawv ci thiab phim. Thaum cov khoom siv laminate siv tooj liab ntawv siv thiab cov txee hlau ntawv yog tsis txaus, yuav tshwm sim tsis zoo tooj liab xov tooj liab.

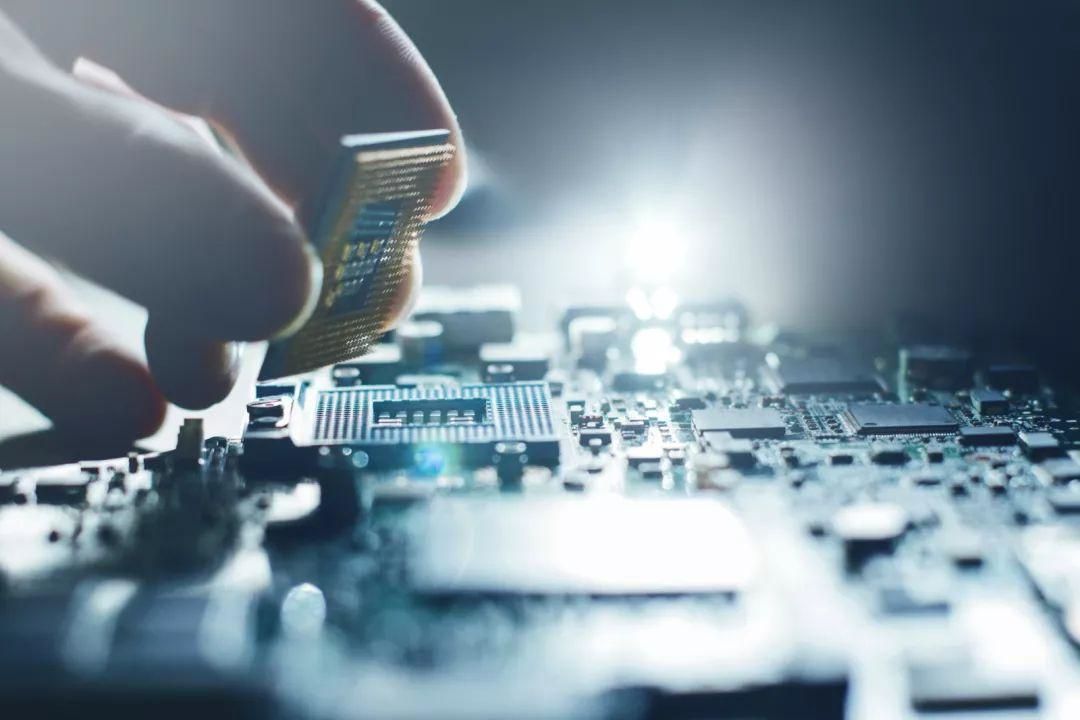

Ntxiv rau, nws yuav yog qhov uas tsis tsim nyog vuam nyob rau hauv tus neeg siv hluav taws xob muaj qhov chaw dav hlau, ntau dua thiab kub kub ntxhov, nws yog qhov yooj yim rau poob tawm):

● Ntau vuam ib qho chaw yuav weld lub ncoo tawm;

● Kub ntawm soldering hlau yog yooj yim rau weld tawm ntawm lub ncoo;

● Cov kev siab ntau dhau qub tau tsim txom los ntawm cov tshuab hlau solding ntawm lub ncoo thiab ntev dhau ntev ntev ntev yuav weld lub hnab ntim tawm.