1. PCB los ntawm lub qhov plating

Muaj ntau txoj hauv kev los tsim ib txheej txheej ntawm plating uas ua tau raws li qhov yuav tsum tau ntawm lub qhov ntsa ntawm lub substrate. Qhov no yog hu ua lub qhov ntsa ua kom muaj kev ua kom muaj kev lag luam. Nws cov qauv PCB cov tuam txhab siv ntau qhov kev tso tsheb hlau luam nruab nrab hauv cov txheej txheem ntau lawm. Txhua qhov chaw cia tso rau lub tank muaj nws tus kheej tswj thiab kev saib xyuas. Los ntawm-qhov elecroadating yog qhov txuas ntxiv tsim kev tsim qauv ntawm cov txheej txheem drilling. Thaum cov laum me kav dhau ntawm tooj liab ntawv ci thiab cov txheej txheem hluav taws xob hauv qab, uas yog cov khoom siv hluav taws xob uas muaj kev phom sij rau cov khoom siv me me.

Lub Resin Molten tseem yuav tawm ib txheej ntawm lub qhov kev tshem tawm thiab cov etchback chemistry. Ib txoj kev uas tsim nyog dua rau cov qauv ntawm cov qauv luam tawm hluav taws xob yog siv cov nplaum tshwj xeeb thiab cov nplaum ua kom zoo nkauj ntawm phab ntsa sab hauv ntawm txhua lub qhov. Nyob rau hauv txoj kev no, tsis tas yuav siv cov txheej txheem tshuaj kho ntau, tsuas yog ib qib kev thov, tuaj yeem tsim cov txheej txheem hluav taws xob txuas ntxiv, nws tuaj yeem tsim hluav taws xob ncaj qha tsis muaj kev kho mob ntxiv. Cov number case no yog cov khoom siv uas muaj cov nplaum uas muaj cov nplaum nplaum uas muaj zog rau feem ntau nrog cov kauj ruam polished, yog li tshem tawm cov theem poledch.

2. Reel Linkage Hom Xaiv Plating

Cov pins thiab pins ntawm cov hluav taws xob sib xyaw, xws li cov sib txuas, sib xyaw ua ke, yog txhua yam kom tau txais kev sib cuag zoo thiab corrosion tsis kam. Txoj kev electroplating no tuaj yeem yog phau ntawv lossis tsis siv neeg, thiab nws yog kim heev los xaiv txhua tus kheej rau plating, yog li huab vuam yuav tsum siv. Feem ntau, ob qho kawg ntawm cov hlau muag dov rau qhov uas yuav tsum tau punchness, tooj liab, tooj liab, tooj liab-ua alloy, thiab lwm yam rau kev txuas hniav ntxiv. Nyob rau hauv lub electroplating txoj kev xaiv plating, ua ntej ntawm txhua yam, ib txheej ntawm cov hlau tooj liab yog coated ntawm cov hlau tooj liab ntawm ib feem ntawm qhov kev xaiv tooj liab ntawv ci yog plated.

3. Ntes-plating Plating

Cov hlau tsis tshua muaj plated ntawm pawg thawj coj ntawm ntug kev sib txuas, cov thawj coj ntawm kev sib cuag lossis tus ntiv tes kub kom muab kev sib cuag tsis kam ua kom tsis kam. Cov txheej txheem no yog hu ua tus ntiv tes plating lossis ib feem ntawm plating. Kub yog feem ntau plated ntawm cov neeg sib tiv tauj ntawm ntug txuas nrog nickel plating nrog txheej sab hauv. Cov ntiv tes kub lossis qhov tiv thaiv ib feem ntawm ntug ntawm cov rooj tsavxwm siv phau ntawv siv lossis siv lub tshuab ua plating. Tam sim no, lub kub plating ntawm kev tiv tauj ntsaws lossis kub ntiv tes tau plated nrog pog thiab txiv neej, plated khawm hloov.

Cov txheej txheem muaj raws li hauv qab no:

1. Sawb cov txheej kom tshem tawm cov tin lossis cov txheej tin-txhuas ntawm cov neeg sib cav sib ceg.

2. Yau nrog ntxuav dej.

3. Cov txhuam nrog cov abrasives.

4. Kev ua kom muaj tog tso rau hauv 10% sulfuric acid.

5. Cov tuab ntawm Nickel plating ntawm cov neeg sib tiv tauj yog 4-5μm.

6. Ntxuav thiab tshem cov dej ntxhia.

7. Kev kho mob ntawm cov kev daws kub.

8. Kub plating.

9. Kev tu.

10. Kom qhuav.

4. Txhuam plating

Nws yog ib qho txheej txheem hluav taws xob ntxiv, thiab tsis yog txhua feem yog raus hauv electrolyte thaum lub sij hawm hluav taws xob. Nyob rau hauv cov txheej txheem hluav taws xob no tsuas yog txwv thaj tsam yog electroplated, thiab nws tsis muaj qhov cuam tshuam ntawm tus so. Feem ntau, cov hlau tsis tshua muaj plated ntawm cov xaiv ntawm cov ntawv luam tawm cov board, xws li cov cheeb tsam uas muaj nyob ntawm ntug txuas. Kev txhuam plating yog siv ntau dua hauv kev kho ntawm cov chaw pov tseg khib nyiab hauv cov khw hluav taws xob hauv hluav taws xob. Qhwv ib qho tshwj xeeb anode (anode uas yog cov tshuaj tsis muaj zog, xws li graphite) nyob rau hauv ib qho kev nqus khoom (cov paj rwb) thiab siv nws nqa cov plating daws tau qhov chaw uas xav tau.

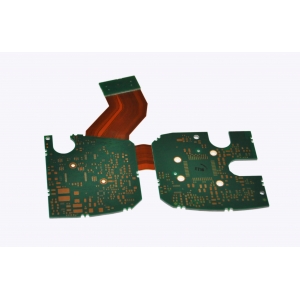

Fastline Circreet Co., Txwv yog tus kws tshaj lij: pcb Circuita Board manufacturing chaw tsim tshuaj paus, kev tsim khoom siv micringave cam, cov xov xwm radar, tuab tus tooj liab ntawv ntawv ci, thiab lwm yam.