Our primary goal is to offer our clients a serious and responsible business relationship, providing personalized attention to all of them for High definition Electronics PCB Board PCBA Assembly with High Quality and SMT Assembly /OEM Service, We sincerely welcome domestic and overseas retailers who phone calls, letters asking, or to vegetation to negotiate, we will present you good quality goods as well as the most enthusiastic assistance,We glance forward in your check out and your cooperation.

Our primary goal is to offer our clients a serious and responsible business relationship, providing personalized attention to all of them for China Multilayer PCB Board and Rigid PCB Board, Our items are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is “to continue to earn your loyalty by dedicating our efforts to the constant improvement of our items and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate”.

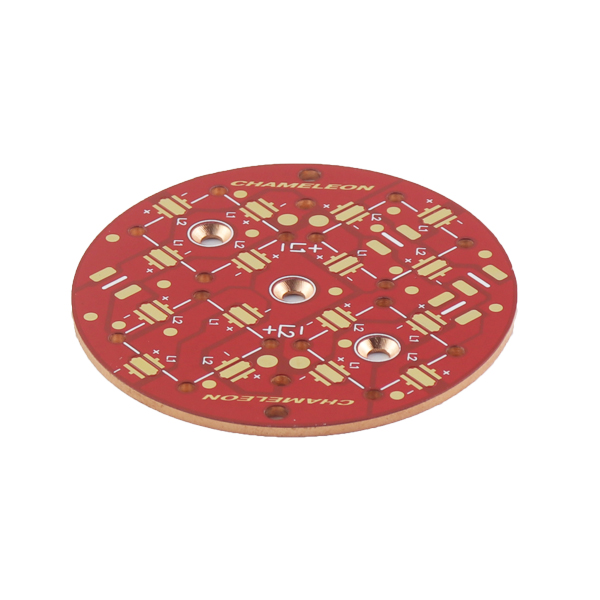

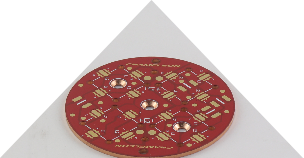

Die Cavity Copper Metal Core PCB

1.Introduction of Die Cavity Copper Metal Core PCB

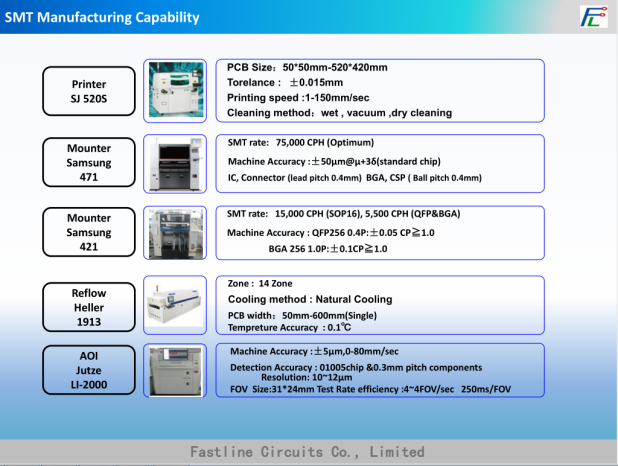

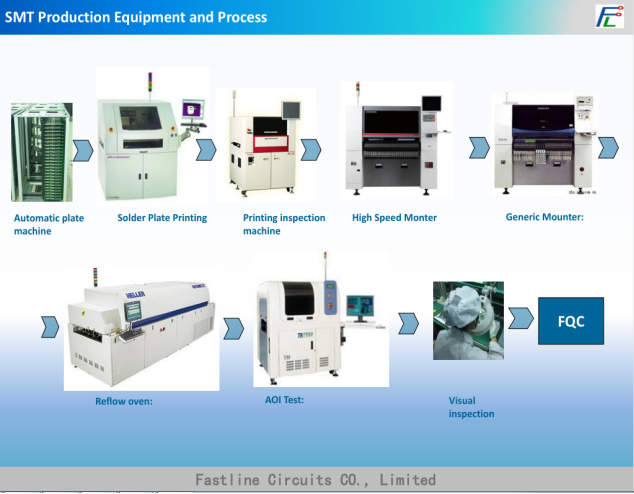

Fastline Circuits is capable of providing full turnkey and partial turnkey printed circuit board assembly services. For full turnkey, we take care of the entire process, including preparation of Printed Circuit Boards, procurement of components, online order tracking, continuous monitoring of quality and final assembly. Whereas for partial turnkey, the customer can provide the PCBs and certain components, and the remaining parts will be handled by us.

Features-Our Products Advantage

1. Over 10 years experience manufacturer in PCB Assemble and PCB field.

2. Big scale of producing makes sure that your purchase cost is lower.

3. Advanced production line guarantees stable quality and long life span.

4. Produce almost any PCB as your requirement.

5. 100% test for all customized PCB products.

6. One-stop Service ,we can help to purchase the components.

Metal Core PCB Capability

| Fastline Metal Core PCB Capability | |

| Materials | Aluminum ,copper |

| Maximum Lager Count | 4 Layers |

| Maximum Panel Size | 17″ x 23″ (432 x 584 mm2) |

| Min. Board Thickness | 1.0mm Al, 4 mils (0.1 mm) FR4 |

| Copper Clad (inner) | 1/2 oz, 1 oz, 2 oz, 3 oz, 4oz |

| Copper Clad (outer) | 1/2 oz, 1 oz, 2 oz, 3 oz, 4 oz |

| Surface Finishes | ENTEK 106A, Immersion Gold, HAL, immersion silver |

| Solder Mask | LPI: Taiyo PSR 4000, Tamura DS2200, Probimer 77MA |

| Minimum Trace (width) | 12.0 mils (0.30 mm) |

| Minimum Trace (spacing) | 12.0 mils (0.30 mm) |

| Minimum PAD-TO-PAD TOL. | ± 3 mils (± 0.76 mm) |

| Hole Size Tolerance (NPTH) | ± 2 mils (± 0.05 mm) |

| Hole Size Tolerance (PTH) | ± 3 mils (± 0.076 mm) |

| Minimum Hole Size | 20 mils (0.50 mm) |

| Outline Dimensional Tol. | < ± 10 mils (0.25 mm) |

| Ionic Cleanliness | < 5 mg/in2 of NaCl (0.775 mg/cm2) |

| Impedance Control | ± 10% (Differential) |

| Warpage | < 1% |

| PCB Prototype Lead Time: | ||

|

item |

General time |

Quick Turn |

|

1-2 Layers |

4 days |

1 days |

|

4-6 Layers |

6 days |

2 days |

|

8-10 Layers |

8 days |

3 days |

|

12-16 Layers |

12 days |

4 days |

|

18-20 Layers |

14 days |

5 days |

|

22-26 Layers |

16 days |

6 days |

| Note:

Base on all data received by us and must be complete and problem free, Lead time is ready to ship. |

||

We believe that the quality is the soul of an enterprise and provides time-critical, technologically advanced engineering and manufacturing services for the electronics industry.

Sound quality gains a good reputation for Fastline. Loyal customers has cooperated with us again and again and new customers come to Fastline to establish cooperation relationship when they hear of the great reputation. We look forward to offering high-quality service to you!

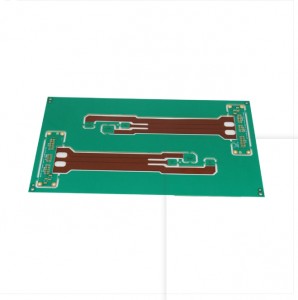

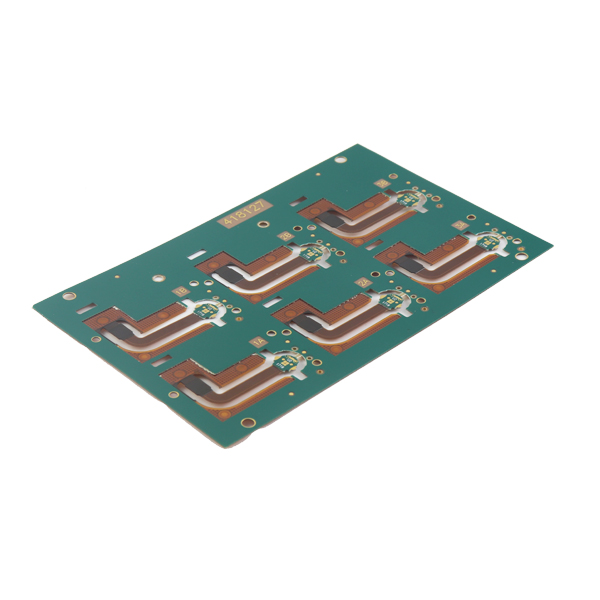

2.Production Details of Die Cavity Copper Metal Core PCB

3.Application of Die Cavity Copper Metal Core PCB

We have served high quality PCBA to numerous countries, from consumer electronics to telecommunications, new energy, aerospace, automotive, etc.

Electronic Product

Communications Industry

Aerospace

Industrial control

Car Manufacturer

Military Industry

4. Qualification of Die Cavity Copper Metal Core PCB

We have set a separated department where exclusive production planner will follow your order production after your payment, to meet your pcb production and assembly requirement.

We have below qualification to prove our pcba.

5.Customer visit

6.Our Package

We use vacuum and carton to wrap the goods, to ensure all them can reach to you completely.

7.Deliver And Serving

You can choose any express company that you have with your account, or our account, for heavier package, seaway shipping will be available, too.

When you get the pcba, don’t forget to check and test them,

If any problem, welcome to contact us!

8.FAQ

Q1: Are you a factory or trade company?

A1: We have our own PCB manufacturing & Assembly factory.

Q2: What’s your minimum order quantity?

A2: Our MOQ is not the same based on different items. Small orders are also welcome.

Q3: what file we should offer?

A3: PCB:Gerber file is better, ( Protel, power pcb, PADs file), PCBA : Gerber file and BOM list.

Q4: No PCB file/GBR file, only have the PCB sample, can you produce it for me?

A4: Yes, we could help you to clone the PCB. Just send the sample PCB to us, we could clone the PCB design and work out it.

Q5: What any other information should be offered except for file?

A5:Following specifications are needed for quotation:

a) Base material

b) Board thickness:

c) Copper thickness

d) Surface treatment:

e) color of solder mask and silkscreen

f) Quantity

Q6:I am very satisfied after I read your information, how can I start to purchase my order?

A6: Please contact our sales at homepage online, thank you!

Q7: What is delivery terms and time?

A7: We usually use FOB terms and ship the goods in 7-15 workdays depending on your order quantity, customization.