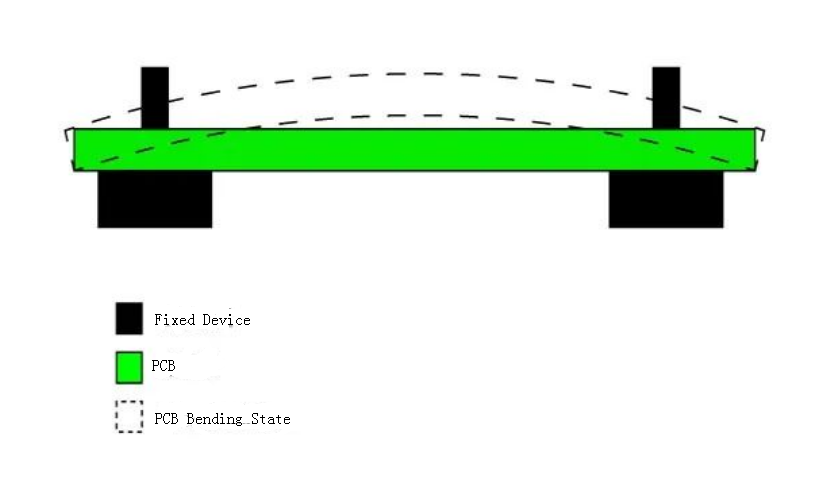

ʻO kaʻoiaʻiʻo, pili pū ka PCB warping i ka piko o ka papa kaapuni, e pili ana i ka papa kaapuni palahalaha mua. Ke kau ʻia ma ka pākaukau, ʻike ʻia nā ʻaoʻao ʻelua a i ʻole ka waena o ka papa i luna iki. Ua ʻike ʻia kēia hanana ʻo PCB warping i ka ʻoihana.

ʻO ke kumu no ka helu ʻana i ka warpage o ka papa kaapuni, ʻo ia ke kau ʻana i ka papa kaapuni ma luna o ka pākaukau me nā kihi ʻehā o ka papa kaapuni ma ka honua a ana i ke kiʻekiʻe o ka pio ma waena. Penei ke kumu:

Warpage = ke kiʻekiʻe o ka pio / ka lōʻihi o ka PCB ʻaoʻao lōʻihi * 100%.

ʻO ka maʻamau ʻoihana warpage papa kaapuni: Wahi a IPC - 6012(1996 edition) "Specification for Identification and Performance of Rigid Printed Boards", ʻo ka nui o ka warpage a me ka distortion i ʻae ʻia no ka hana ʻana o nā papa kaapuni ma waena o 0.75% a me 1.5%. Ma muli o ka ʻokoʻa kaʻina hana o kēlā me kēia hale hana, aia kekahi mau ʻokoʻa i nā koi hoʻomalu warpage PCB. No ka 1.6 papa mānoanoa maʻamau papalua-ʻaoʻao multilayer kaapuni papa, ka hapanui kaapuni papa Manufacturers ke hoomalu i ka PCB warpage ma waena o 0.70-0.75%, he nui SMT, BGA papa, koi i loko o ka laulā o 0.5%, kekahi kaapuni papa hale hana me ka ikaika kaʻina hana hiki ke hoala. ka PCB warpage maʻamau i 0.3%.

Pehea e pale aku ai i ka warping o ka papa kaapuni i ka wā hana?

(1) Pono ka hoʻonohonoho semi-cured ma waena o kēlā me kēia papa, ʻo ka ʻāpana o nā papa kaapuni ʻeono, ʻo ka mānoanoa ma waena o 1-2 a me 5-6 papa a me ka helu o nā ʻāpana semi-cured e kūlike;

(2) Pono e hoʻohana ka papa nui PCB multi-layer a me ka pepa curing i nā huahana like a ka mea hoʻolako;

(3) ʻO ka ʻaoʻao waho A a me B o ka ʻāpana kiʻi laina e like me ka hiki, inā he ʻili keleawe nui ka ʻaoʻao A, ʻo ka ʻaoʻao B he mau laina liʻiliʻi wale nō, maʻalahi kēia kūlana ma hope o ka etching warping.

Pehea e pale ai i ka warping o ka papa kaapuni?

1.Engineering design: interlayer semi-curing pepa hoʻonohonoho pono e kūpono; E hana ʻia ka papa nui multilayer a me ka pepa semi-cured mai ka mea hoʻolako like; ʻO kahi kiʻi kiʻi o ka mokulele C/S o waho e kokoke loa ana, a hiki ke hoʻohana ʻia kahi mānoanoa kūʻokoʻa.

2. Drying pā ma mua blanking: maʻamau 150 degere 6-10 hola, hoʻokaʻawale i ka wai mahu i loko o ka pā, hana hou i ka resin curing loa, hoopau i ke kaumaha i loko o ka pā; ʻO ka pepa bakena ma mua o ka wehe ʻana, pono ka papa o loko a me ka ʻaoʻao pālua!

3.Before laminates, noonoo pono i ka weft a me ka weft kuhikuhi o solidified pā: ka weft a me ka weft shrinkage lākiō, a me ka noonoo pono e hoʻokaʻawale i ka weft a me ka weft kuhikuhi ma mua laminating semi-solidified pepa; Pono e hoʻolohe ka papa kumu i ke kuhikuhi o ka warp a me ka weft; ʻO ka ʻaoʻao maʻamau o ka ʻaoʻao lapaʻau ʻo ka ʻaoʻao meridian; ʻO ke kuhikuhi lōʻihi o ka pā keleawe keleawe he meridional; 10 papa o 4OZ mana mānoanoa pepa keleawe

4. ka mānoanoa o ka lamination e hoʻopau i ke koʻikoʻi ma hope o ke kaomi ʻana i ke anu, e ʻoki i ka lihi maka;

5.Baking pā ma mua o ka wili ʻana: 150 degere no 4 mau hola;

6. ʻOi aku ka maikaʻi ʻaʻole e hele i loko o ka pulupulu mīkini wili, ʻōlelo ʻia ka hoʻomaʻemaʻe kemika; Hoʻohana ʻia ka mea paʻa kūikawā no ka pale ʻana i ka pā mai ka piko a me ka pelu

7.After spraying tin ma luna o ke kinikini palahalaha a i 'ole ka pā kila maoli hooluolu ana i ka lumi wela a me ka ea lana moe hooluolu ma hope o ka hoʻomaʻemaʻe;