Ma keʻano laulā: ke hoʻohālikelikeʻia me ke kaʻina hana o ka papa multi-layer a me ka papa pālua, aia he 2 mau kaʻina hana, i kēlā me kēia: laina i loko a me ka lamination.

Ma ka kikoʻī: i ka hana ʻana o ka pā pālua pālua, ma hope o ka pau ʻana o ka ʻoki ʻana, e hoʻokō ʻia ka wili, a laila i loko o ke keleawe, ka laina; I ke kaʻina hana o ka papa multi-layer, ma hope o ka wehe ʻia ʻana o ka mea, ʻaʻole ia e wili pololei ʻia, akā pono e hele mua i ka laina i loko a me ka lamination, a laila i loko o ka hale hana wili e wili ai, a laila. i ke keleawe a me ka laina.

ʻO ia hoʻi, ma waena o ka wehe ʻana a me ka ʻeli ʻana, ʻelua mau kaʻina o ka "laina i loko" a me ka "lamination". ʻO ka mea i luna nei ka ʻokoʻa ma waena o ka papa multi-layer a me ka hana papa pālua.

A laila, e nānā kākou i nā hana ʻelua o ka laina i loko a me ka lamination

Laina i loko

ʻO ke kaʻina hana "laina" i ka hana ʻana i nā papa pālua ʻelua, me ka paʻi kiʻiʻoniʻoni, ka hoʻolaha ʻana, ka hoʻomohala ʻana (inā poina ʻoe, hiki iā ʻoe ke hoʻi a nānā iā ia).

ʻAʻole maʻalahi ka "kaapuni i loko" ma aneʻi! Ma waho aʻe o ka kiʻiʻoniʻoni laminated i loko, ka ʻike i loko, ka hoʻomohala ʻana i loko, e komo pū kekahi i loko o ka hoʻomaʻamaʻa mua ʻana, ka etching i loko, ka wehe ʻana i ka kiʻiʻoniʻoni a me ka AOI i loko.

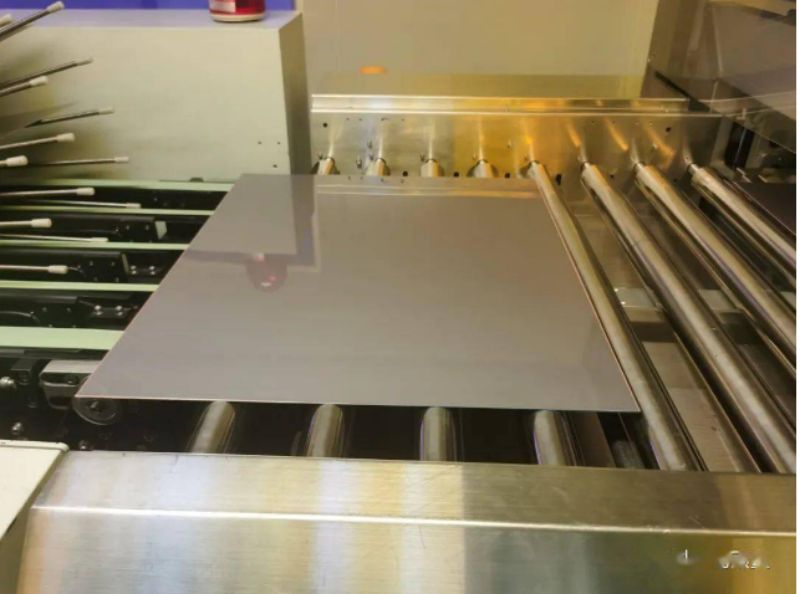

I ke kaʻina hana papa pālua ʻelua, ʻo ka papa ma hope o ka hoʻopaʻa ʻana i ke keleawe, me ka ʻole o ka laina hana, pololei i loko o ke kiʻi paʻi, no laila ʻaʻohe pono e hana hou i ka mālama mua. A ʻo ka pā keleawe keleawe ma aneʻi, i hele mai mai ka hale ʻokiʻoki, e loaʻa i ka ʻili o ka papa nā mea haumia, no laila

Ma mua o ke kiʻi laminate i loko, pono ia e holomua i ka mālama ʻana a me ka hoʻomaʻemaʻe ʻana, ka hoʻohana ʻana i ka hopena kemika, e wehe mua i ka aila, ka wai, ka wai maʻemaʻe, ʻelua micro-etching (e wehe i ka lepo lepo), a laila wai, a laila pickling ka holoi ʻana, e oxidized ka ʻili, no laila pono ia i ka pickling), a laila wai, a laila maloʻo, a laila i loko o ke kiʻi laminate i loko.

Kiʻi laminate i loko ma mua o ka mālama ʻana

Ma hope o ke kaomi ʻana i ka papa, no ka mea ʻaʻole i wili ʻia, ʻano palahalaha loa.

ʻO ka paʻi kiʻiʻoniʻoni, hōʻike, hoʻomohala ʻana, nā mea kikoʻī o kēia mau loulou, ua hoʻokomo ʻia i loko o ka ʻatikala o ka hana pālua pālua, ʻaʻole e hana hou ʻia.

Ma hope o ka pauʻana o ka hoʻomohalaʻana, e hōʻikeʻia kahi hapa o ke keleawe, no ka mea,ʻo ka papa waho he hana kiʻiʻoniʻoni maikaʻi,ʻo ka papa o loko he hana kiʻiʻoniʻoni maikaʻiʻole. No laila, ma hope o ka pau ʻana o ka hoʻomohala ʻana o ka papa o waho, ʻo ka laina keleawe i hōʻike ʻia ka ʻāpana e pono e mālama ʻia, a ʻo ke keleawe i hōʻike ʻia ma hope o ka hoʻomohala ʻana o ka papa i loko ka ʻāpana e pono ai ke kālai ʻia, no laila,

ʻOkoʻa nō hoʻi ke kaʻina hana etching i loko a me ke kaʻina hana waho, ʻo ka etching i loko he kaʻina alkaline, i ka manawa o ka etching, aia mau ke kiʻi maloʻo, ʻo ka ʻāpana me ka ʻole o ka kiʻiʻoniʻoni maloʻo (exposed copper) ua kahakaha mua ʻia, a a laila wehe ʻia ka ʻōpala.

Hoʻokuʻu mua ʻia ka etching o ka papa waho a laila etched, a pale ʻia ka laina e ka ipu wai.

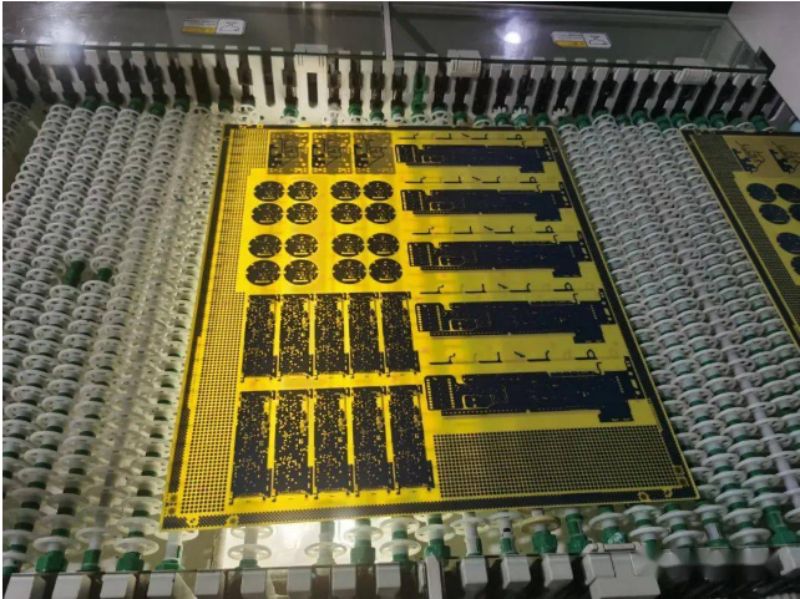

Inner film etching line, the left is responsible for etching, the right is responsible for film withdrawal.

Ma hope o ke kalai ʻana i ka papa kaapuni, ua kālai ʻia ke keleawe keu aku, a ʻaʻole i wehe ʻia ke koena o ke kiʻi maloʻo.

ʻO ka papa kaapuni ma hope o ka wehe ʻana.

Ma hope o ka pau ʻana o ka papa o loko o ke kiʻiʻoniʻoni, hoʻopau piha ʻia ka papa o loko o ka laina, i kēia manawa, a laila ʻike ʻia ʻo AOI optical, e hoʻoholo ai ʻaʻohe pilikia, hiki iā ʻoe ke hoʻokō i ke kaʻina hana lamination.

Lamination:

Hana wale i ka papa, kapa mākou ʻo ka papa i loko, inā he 4 papa o ka papa, he 1 ka papa o loko, inā he 6 papa o ka papa, aia he 2 papa o loko.

ʻO ke kumu nui o kēia kaʻina hana, ʻo ia ka hoʻopaʻa ʻana i ka pā i loko a me ka papa o waho i hoʻopaʻa ʻia a lilo i mea holoʻokoʻa. ʻO ke kuleana no ka mea hoʻopaʻa, i kapa ʻia ʻo PP, Kina i kapa ʻia he semi-curing sheet, ʻo ka mea nui ka resin a me ke aniani fiber, e pāʻani pū ʻo ia i ka papa i loko a me ke kumu o ka insulation copper foil.

I mea e hōʻoia ai i ka maikaʻi o ka papa multi-layer, ʻo ka mea hoʻolako PP o Jialichuang ʻo ia nō ʻo South Asia Electronics.

Ma keʻano laulā, ua māhele ʻia ke kaʻina hana lamination i ʻehā mau ʻanuʻu: Browning, pre-stacking, platen, and pressing. A laila, e nānā kaʻawale i nā kikoʻī o kēlā me kēia kaʻina. ʻO ka papa kaapuni browned e hoʻohui i kahi papa kiʻiʻoniʻoni browned ma ka ʻili o ka papa kaapuni, he mea ʻeleʻele metala ʻole, a ʻaʻole kūlike kona ʻili, i mea e maʻalahi ai ka hoʻopaʻa ʻana me PP.

Ua like ke kumumanaʻo me ka hoʻoponopono ʻana i ke kaʻa paikikala, pono e waiho ʻia ka wahi i haki me kahi faila e hoʻomaikaʻi ai i ka hoʻopili ʻana i ke kāpili.

ʻO ke kaʻina Browning kekahi kaʻina hana kemika, e hele i ka pickling, ka holoi alkali, ka holoi multi-channel, hoʻomaloʻo, hoʻoluʻu a me nā hana ʻē aʻe.

prelap

ʻO ke kaʻina hana pre-stacking, i hana ʻia i loko o kahi hale hana lepo ʻole, e hoʻopaʻa pū i ka pā kumu a me ka PP. Hoʻonoho ʻia kahi PP ma kēlā me kēia ʻaoʻao o ka pā kumu. ʻO ka lōʻihi a me ka laula o PP he 2mm ka nui ma mua o ka pā kumu e pale ai i nā ʻaoʻao ākea ma hope o ke kaomi ʻana.

Raft:

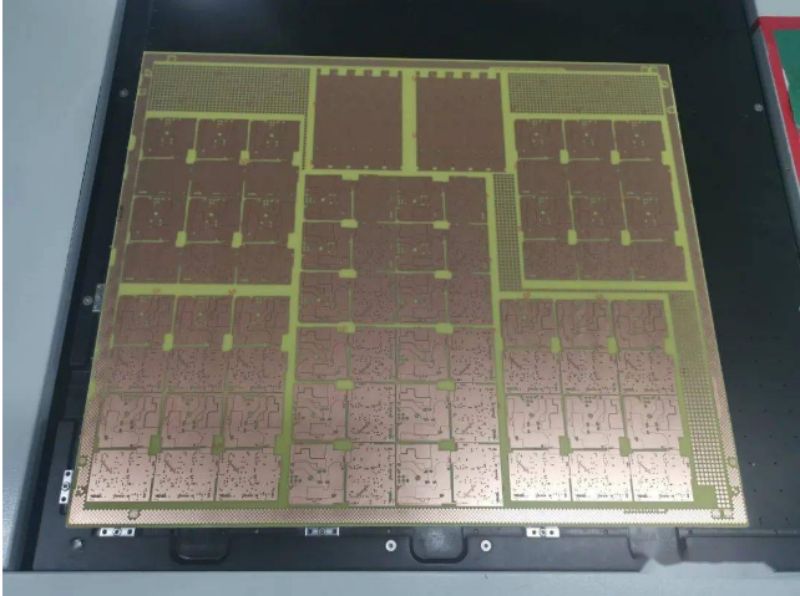

ʻO ke kumu nui o ka papa lālani e hoʻohui i kahi papa keleawe ma luna o ka papa PP e hoʻomākaukau ai no ka laina o waho. Eia hou, e hoʻohuiʻia ka pā kila a me ka pepa kraft i ka papa o waho.lamination

ʻO nā hana mua e hoʻomākaukau ai no ka lamination hope.

Ma mua o ka laminating, i mea e pale ai i ka warping, aia kahi pā uhi, ma kahi o 12mm mānoanoa, kila.

Hoʻokomo ʻia ka laminating i ʻelua kaʻina o ka paʻi wela a me ke kaomi anu, i loko o ka paʻi wela a me ka paʻi anu. He loulou koʻikoʻi kēia, e noʻonoʻo i nā mea e pili ana i ka vacuum, ka mahana, ke kaomi, ka manawa, hui pū kēia mau mea me kekahi, i mea e hana ai i nā papa kaapuni kiʻekiʻe.

No ka laʻana, i kekahi manawa, pehea ka nui o ka mahana, ka nui o ke kaomi, a me ka lōʻihi o ka manawa e pono ai, pono e hoʻoponopono pololei ʻia.

Ma hope o ka pau ʻana o kēia kaʻina hana, e hoʻopili pono ʻia ka PP a me ka pā i loko a me ka pahu keleawe waho.

Ma hope o ka puka ʻana i waho o ka paʻi paʻi, lawe ʻia ka hoʻopau ʻana i ka mīkini, wehe ʻia ka pā kila, a hoʻouna hou ʻia i ka lumi platoon ma hope o ka wili ʻana. E like me ka mea i hōʻike ʻia ma ka Figure 11, ke wehe nei ka mīkini i ka pā kila.

E hoʻihoʻi ʻia ka papa kaapuni laminated multi-layer i kāna hale hana wili mua e wili ai, a ʻo ke koena o ke kaʻina hana e like me ke kaʻina hana o ka papa pālua.