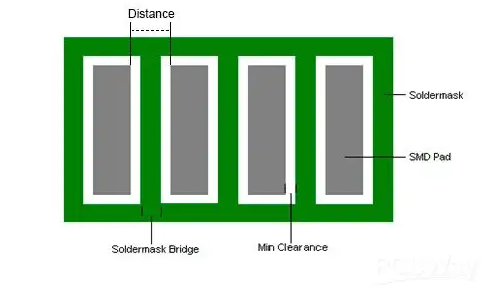

Ma mua o ka hoʻokomo ʻana i ka puka aniani solder mask, pono mākou e ʻike i ke ʻano o ka solder mask. ʻO ka mask solder e pili ana i ka ʻāpana o ka papa kaapuni i paʻi ʻia i ka inika, i hoʻohana ʻia e uhi i nā ʻāpana a me ke keleawe e pale aku i nā mea metala ma ka PCB a pale i nā pōkole pōkole. ʻO ka wehe ʻana i ka pale huna solder e pili ana i ka wehe ʻana i kahi puka ma ka ʻāpana solder mask i hiki ke hana ʻia ke kuʻi ʻana ma ka wehe. ʻO kēlā me kēia wahi kahi i paʻi ʻole ʻia ai ka mask solder hiki ke kapa ʻia he wehe pukaaniani. ʻO kahi kahi i paʻi ʻole ʻia ai ka mask solder me nā pad soldered, patch pads, slot positions, a pēlā aku. Aia kekahi hihia i kapa ʻia he puka puka hāmama. ʻO ka puka aniani hāmama, ʻo ia hoʻi, ʻaʻole i uhi ʻia ka ʻaoʻao o ka papa me ka mask solder, a ua uhi ʻia kekahi me ka solder mask.

一. Pehea e hoʻokaʻawale ai "ma ka puka makani" a me "ma ka ʻaila uhi"

Hiki ke lohe pinepine ʻia nā huaʻōlelo "via windowing" a me "via cap oil" ma ka hoʻolālā papa kaapuni. ʻO kaʻoiaʻiʻo,ʻo ia keʻano o ka weheʻana o kekahi i ka puka makani i ka puka, aʻo kekahi e uhi i ka puka me kaʻaila. I nā huaʻōlelo ʻē aʻe, inā e hoʻokaʻawale i ka ʻili o ka PCB..

E wehe ana i ka puka makani'o ia ho'i, hiki ke ho'opa'a 'ia ma kahi i wehe 'ia ai ka puka makani, a 'o ka wehe 'ana i ka puka makani hiki ke ho'okolokolo 'ia e like me ka hiki ke pani 'ia. ʻO ka ʻaila uhi e pili ana i ka ʻoiaʻiʻo ʻaʻole maʻalahi ke kī i ka wā o ka patch, i hoʻoholo ʻia e ke kaʻina hana. ʻO nā kumu i manaʻo ai ka vias ʻaʻole i uhi ʻia i ka aila penei: no ka mea he wai ka ʻaila solder mask a ʻaʻohe ka waena o nā puka vias, maʻalahi ka ʻaila e komo i nā puka via i ka wā o ka kuke ʻana. ka ʻaila solder mask ma ke apo solder mask. ʻO ka hopena, hiki mai ka melemele o nā vias. ʻO kēia kūlana e pili ana i ka manaʻo o ka solder e kū'ē i kaʻaila, ka umu a me ka ikaika, no laila, aia kekahi mau hihia i hiki keʻikeʻia ka'ōmaʻomaʻo ma luna, aʻo nā mea'ē aʻeʻaʻole hiki.

二. No ke aha mākou e pono ai e wehe i ka puka makani no ka pale pale?

No nā vias, inā ʻaʻole i wehe ʻia ka puka makani, e komo ka ʻīnika o ka mask solder i ka lua. No kekahi mau puka ʻaʻole koi i nā puka ʻīnika, pono e hoʻolālā iā lākou ma o nā puka. No nā mea i kau ʻia ma loko o ka puka, inā ʻaʻole kūʻai ʻia ka PCB e wehe i ka puka makani, ʻaʻole hiki ke kūʻai ʻia nā ʻāpana i ka papa maʻamau. ʻO ka wehe ʻana ʻaʻole wale he hana o ka kuʻi ʻana maʻalahi, akā hiki ke ana ʻia ma vias. Hiki ke hoʻohana ʻia ka wehe ʻana o ka mask solder no nā lua ma kekahi mau kūlana kūikawā e ana i nā vias me kahi multimeter..

No ka PCB, inā ʻaʻole i wehe ʻia ka puka makani, ʻaʻole hiki ke hoʻokō ʻia ka mālama ʻana i ka ʻili, ʻaʻole hiki ke hana ʻia ke kīpī a me ka welding.

三.Pehea e wehe ai i ka puka makani no ka pale pale?

1. Ma ka hoʻolālā, e wehe ka pad i ka puka makani ma ke ʻano maʻamau (OVERRIDE: 0.1016mm), ʻo ia hoʻi, ua hōʻike ʻia ka pad i ke keleawe keleawe, a ʻo ka hoʻonui ʻana i waho he 0.1016mm, a ua hoʻopaʻa ʻia ka nalu. ʻAʻole ʻōlelo ʻia nā hoʻololi hoʻolālā e hōʻoia i ka solderability

2. Ma ka maʻamau, e loaʻa i ka puka ma ka puka makani (OVERRIDE: 0.1016mm) i ka hoʻolālā, ʻo ia hoʻi, ʻike ʻia ka puka ma ke keleawe foil, ʻo ka hoʻonui ʻana i waho he 0.1016mm, a e hoʻohana ʻia ke tin i ka wā o ka nalu ʻana. Inā ʻo ka hoʻolālā e pale aku i nā vias mai ka tinning a ʻaʻole e hōʻike i ke keleawe, pono ke nānā ʻia ke koho PENTING i nā waiwai hou o ka SOLDER MASK e pani i ke ala.

3. Eia kekahi, hiki ke hoʻohana ʻia kēia papa no nā wili uila ʻole wale nō, a ʻo ka ʻaila solder mask e wehe i ka puka makani e like me ia. Inā aia ma ka ʻaoʻao keleawe keleawe, hoʻohana ʻia ia e hoʻonui i ka mana overcurrent o ka trace, a hiki ke hoʻopaʻa ʻia i ka wā kūʻai. Inā aia ma luna o kahi ʻano keleawe keleawe ʻole, ua hana maʻamau ia no ka paʻi ʻana i ka pale siliki o nā logos a me nā kiʻi kūikawā, hiki ke mālama i ka hana.