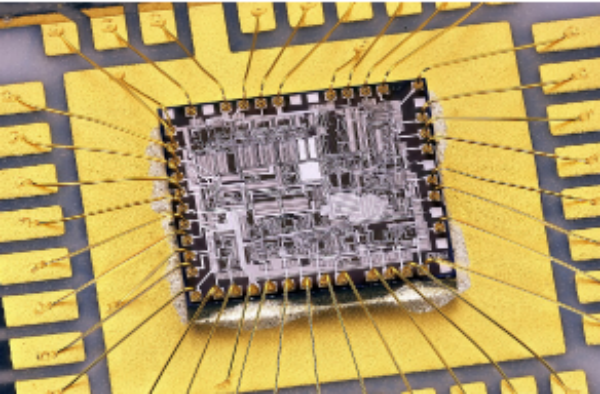

Haɗin waya– Hanyar hawa guntu akan PCB

Akwai kwakwalwan kwamfuta 500 zuwa 1,200 da aka haɗa zuwa kowane wafer kafin ƙarshen tsari. Domin amfani da waɗannan guntuwar a inda ake buƙata, wafer ɗin yana buƙatar a yanka shi cikin kwakwalwan kwamfuta guda ɗaya sannan a haɗa shi zuwa waje kuma a kunna shi. A wannan lokacin, hanyar haɗa wayoyi (hanyoyin watsawa don siginar lantarki) ana kiran su haɗin haɗin waya.

Abun haɗin waya: zinariya /aluminum / jan karfe

Ana ƙayyade kayan haɗin waya ta hanyar yin la'akari da cikakken la'akari da sigogin walda daban-daban da haɗa su cikin hanya mafi dacewa. Siffofin da ake magana a kai a nan sun ƙunshi al'amura da yawa, gami da nau'in samfurin semiconductor, nau'in marufi, girman kushin, diamita na gubar ƙarfe, hanyar walda, da kuma alamomin dogaro kamar ƙarfin ƙarfi da haɓakar gubar ƙarfe. Abubuwan gubar ƙarfe na yau da kullun sun haɗa da zinariya, aluminum da jan karfe. Daga cikin su, ana amfani da waya ta zinare mafi yawa don marufi na semiconductor.

Wayar Zinariya tana da kyakykyawan kyamar wutar lantarki, tana da kwanciyar hankali ta sinadarai, kuma tana da juriya mai ƙarfi. Duk da haka, babban rashin lahani na waya ta aluminum, wanda akasari ana amfani dashi a farkon zamanin, shine yana da sauƙin lalata. Bugu da ƙari, taurin wayar zinare yana da ƙarfi, don haka ana iya ƙirƙirar shi da kyau a cikin ƙwallon ƙafa a cikin haɗin gwiwa na farko, kuma yana iya samar da madaidaicin madaurin jagorar semicircular (Madauki, daga haɗin farko zuwa haɗin gwiwa na biyu) a cikin haɗin gwiwa na sakandare. siffar da aka samu).

Wayar Aluminum tana da diamita mafi girma da girma fiye da wayar zinare. Don haka, ko da za a yi amfani da wayar zinari mai tsafta don samar da madauki na gubar, ba za ta karye ba, amma za ta karye cikin sauki, sai a gauraya ta da siliki ko magnesium a yi abin da ya dace. Ana amfani da waya mafi girma a cikin marufi masu zafi (kamar Hermetic) ko hanyoyin ultrasonic inda ba za a iya amfani da waya ta gwal ba.

Duk da cewa wayar jan karfe tana da arha, taurinsa ya yi yawa. Idan taurin ya yi tsayi da yawa, ba zai zama da sauƙi a samu siffar ƙwallon ƙafa ba, kuma akwai iyakoki da yawa lokacin ƙirƙirar madaukai na gubar. Bugu da ƙari, dole ne a yi amfani da matsa lamba akan guntu kushin yayin aikin haɗin ƙwallon. Idan taurin ya yi yawa, tsage-tsage za su bayyana a cikin fim ɗin a ƙasan kushin. Bugu da kari, za a yi wani abu na "peeling" wanda a cikinsa damtsen da aka haɗa kushin ya bare. Duk da haka, tun da karfen wayoyi na guntu an yi shi da tagulla, ana samun karuwar yanayin amfani da wayar tagulla a zamanin yau. Tabbas, don shawo kan gazawar wayar tagulla, yawanci ana haɗe shi da ɗan ƙaramin abu don samar da gami sannan a yi amfani da shi.