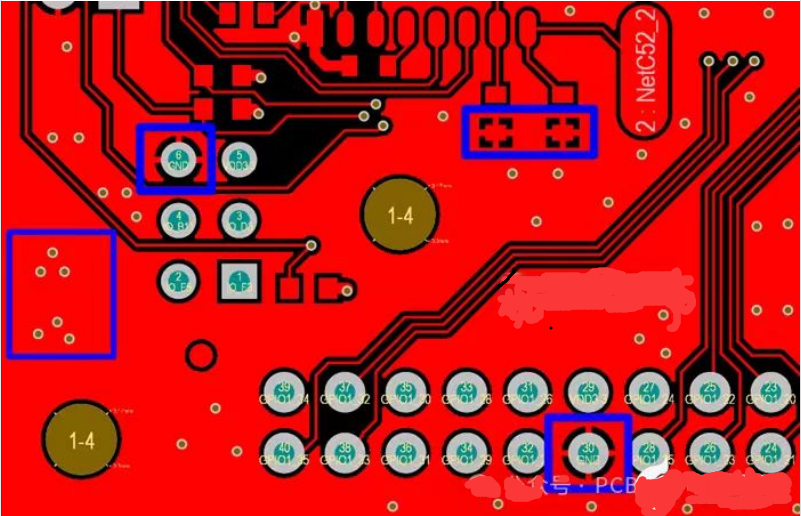

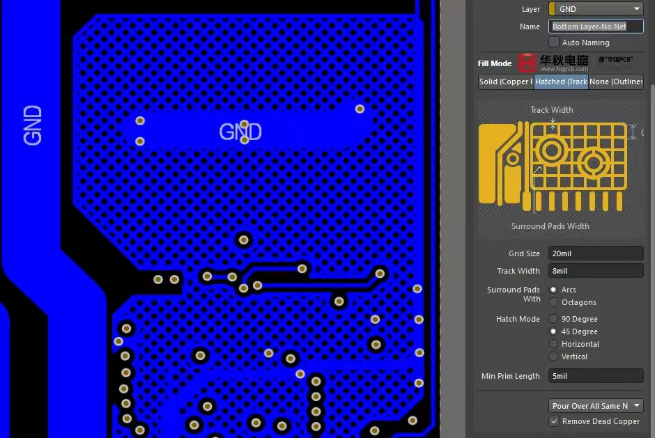

Bayan duk abun cikin ƙira na PCB an tsara shi, yawanci yana ɗaukar mabuɗin matakin na ƙarshe - kwanciya tagulla.

Don haka me ya sa kuka yi kwanciya da tagulla a ƙarshe? Shin ba za ku iya sa shi ba?

Don PCB, aikin jan karfe yana da yawa, irin su rage ƙasa mai ban tsoro da haɓaka ikon shiga na anti-; An haɗa shi da waya ta ƙasa, rage yankin madauki; Kuma taimaka tare da sanyaya, da sauransu.

1, jan ƙarfe na iya rage ƙasa mai ban sha'awa, da kuma samar da kariya garkuwa da shafewar amo.

Akwai rijiyoyin da yawa na ƙwayar ƙwayar cuta a cikin da'irar dijital, don haka ya fi cancanta don rage haɓakar ƙasa. Dawowar jan ƙarfe hanya ce ta yau da kullun don rage yawan ƙasa.

Taro na iya rage juriya na ƙasa ta ƙara yawan yankin da aka kawo asali yanki na waya. Ko taƙaitaccen tsawon waya na ƙasa, rage shigarwar ƙasa waya, kuma ta haka ne rage rashin daidaituwa na waya waya; Hakanan zaka iya sarrafa karfin waya waya, don inganta waya ta ƙasa da ta dace da ta inganta lantarki da waya ta ƙasa kuma rage rashin daidaiton ƙasa.

Babban yanki na ƙasa ko jan ƙarfe mai ƙarfi na iya kunna aikin kare kai, yana taimakawa rage tsangwama na lantarki, inganta iyawar hana tsangwama game da da'irar, da kuma biyan bukatun EMC.

Bugu da kari, don da'awar miji, paving jan ƙarfe yana ba da cikakkiyar hanyar dawowa don sigina na divaling na mitar, ta rage wayoyin sadarwar DC.

2, kwanciya tagulla na iya inganta ƙarfin ƙarfin zafi na PCB

Baya ga rage ƙasa mai ban sha'awa a cikin PCB zane, ana iya amfani da jan ƙarfe don diski.

Kamar yadda dukkanmu mun sani, ƙarfe yana da sauƙin yin amfani da wutar lantarki da kayan zafi, don haka idan an fitar da PCB tare da jan ƙarfe, don haka yana da sauƙin diskon jirgin da kuma sauran allon PCB.

A kwance jan ƙarfe shima yana taimakawa rarraba zafi a ko'ina, yana hana kirkirar wuraren shakatawa na gida. Dangane da rarraba zafi zuwa ga duka hukumar PCB, ana iya rage maida hankali na gida, ana iya inganta zafin jiki na zafin rana, kuma za'a iya inganta ingancin zafin rana.

Saboda haka, a cikin PCB zane, za a iya amfani da jan karfe don zafin rana a cikin hanyoyi masu zuwa:

Yankunan da aka tsara yanayin zafi: Dangane da tushen tushen PCB, wurare masu kyau sosai, kuma suna ƙaruwa da ƙarfe mai zafi a cikin waɗannan yankuna da hanya mai zafi.

Araara kauri daga jan karfe tsare: kara kauri daga jan karfe na iya ƙara yawan aiki da zafin rana.

Designer Heat Dispation ta hanyar ramuka: Designer Heat Dispation ta hanyar ramuka a cikin zafin rana a cikin zafi wucin gadi ta hanyar ramuka don ƙara ƙarfin ramuka da haɓaka ƙarfin zafi.

Araukar ruwa mai zafi: ƙara zafi nutse a cikin yankin da aka lalata, sannan zafi a cikin zafin rana ta hanyar haɗuwa ta zahiri don haɓaka ƙarfin zafi.

3, kwanciya jan karfe na iya rage ƙazanta da inganta ingancin PCB

Faurarda jan karfe na iya taimaka da tabbatar da daidaituwar da bautar, rage lalata farantin a lokacin aikin LamInation, musamman don PCB na biyu ko Multi-Layer na PCB.

Idan rarraba leda a wasu yankuna ya yi yawa, da kuma rarrabawa a wasu yankuna sun yi kadan, zai iya haifar da rikicewar duka hukumar, da jan ƙarfe za ta iya rage wannan rata.

4, don biyan bukatar shigarwa na na'urori na musamman.

Don wasu na'urori na musamman, kamar na'urorin da ke buƙatar ƙasa ko buƙatun na musamman, yana sa ido sosai, haɓaka kwanciyar hankali da amincin na'urar.

Sabili da haka, dangane da fa'idodin da ke sama, a mafi yawan lokuta, masu zanen zamani zasu ɗora a kan allon PCB.

Koyaya, kwanciya tagulla ba ya zama dole wani ɓangare na ƙirar PCB ba.

A wasu halaye, kwanciya jan ƙarfe bazai dace ko mai yiwuwa ba. Anan akwai wasu maganganu inda bai kamata a yadu da ƙarfe ba:

A), babban layin sigina na mita:

Don layin sigina na mita, kwanciya jan ƙarfe na iya gabatar da ƙarin masu ɗaukar hoto da waɗanda ke ba da shiga cikin siginar. A cikin Cirrence mai girma, yawanci ya zama dole don sarrafa yanayin mafita na waya da rage hanyar dawowa, maimakon over-kwance jan ƙarfe.

Misali, kwanciya jan ƙarfe na iya shafar kashi na siginar eriya. Kwantar kwanciya a cikin yankin kusa da eriya yana da sauƙin haifar da siginar da aka tattara don karɓar babban tsangwama. Alamar Antenna tana da tsauri ga tsarin sifarwar Extsifier, da kuma rashin daidaituwa na kwanciya zai shafi wasan kwaikwayon amplifier kewaye. Don haka yankin da ke kusa da eriyar sashe yawanci ba a rufe da tagulla.

B), Hukumar Call Manyan Gidara:

Don babban allon allo mai yawa, sanyawa na tagulla na iya haifar da gajeren da'irori ko matsalolin ƙasa tsakanin layi, yana shafar aikin al'ada na da'irar. Lokacin da ƙirar allon katako mai yawa, ya zama dole a tsara tsarin jan ƙarfe da kyau don tabbatar da cewa akwai wadataccen spacing da rufi tsakanin layin don guje wa matsaloli.

C), zafi watsipation da sauri, walda matsaloli:

Idan fil daga wani abu ya cika da tagulla da jan karfe, yana iya haifar da matsanancin zafi mai zafi, wanda ya sa ya zama da wahala a cire walda da gyara. Mun sani cewa aikin ƙarfe na theream yana da girma sosai, don haka ko an yi amfani da welding, don haka ƙuruciyar tagulla zata iya amfani da walwala da sauƙaƙe waldi.

D), bukatun muhalli na musamman:

A wasu mahalli na musamman, kamar babban zafin jiki, babban yanayi, yanayi mai rauni, ana iya lalata yanayin jan ƙarfe, don haka ya shafi aiwatarwa da amincin jirgin PCB. A wannan yanayin, ya zama dole don zaɓar kayan da ya dace da magani gwargwadon takamaiman bukatun muhalli, maimakon over-kwanciya jan ƙarfe.

E), matakin na musamman na allo:

Don sassauci mai sassauci, ƙwanƙwasa jirgi a cikin katako, yana da muhimmanci a sanya matsalar sassauƙa da sassauƙa da sassauza.

A taƙaice, a cikin ƙirar PCB, wajibi ne don zaɓa tsakanin tagulla da waɗanda ba harafin tagulla ba bisa ga takamaiman buƙatun da'ira, bukatun na musamman.