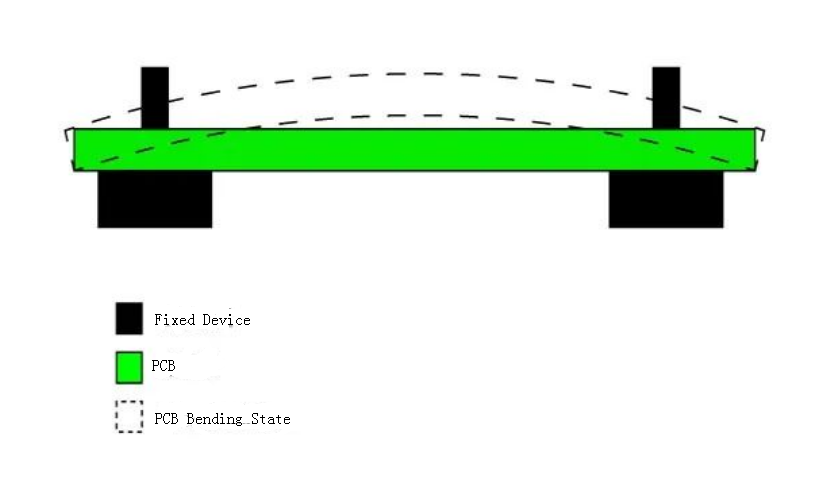

A gaskiya ma, SCB yana nufin lanƙwasa hukumar da'irar, wanda ke nufin ainihin kujerun lebur da'ira. A lokacin da aka sanya a kan tebur, biyu ƙare ko tsakiyar allon ya bayyana dan kadan sama. Wannan sabon abu an san shi kamar yadda PCB a cikin masana'antar.

Tsarin tsari don lissafin warpage jirgin shine don sa ɗakin ɗakin jirgin shine a kan tebur tare da kusurwoyin huɗu tare da ma'aunin dutsen a tsakiya. Tsarin kamar haka:

Warpage = tsawo na baka / Tsawon PCB na dogon PCB * 100%.

Staffist Holegilage masana'antu: A cewar IPC - 6012 (1996 Edition) "Tsallake da aka ba da izini don samar da allon da aka buga da kuma murabba'i mai gudana da 1.5%. Sakamakon karfin tsari daban-daban na kowane masana'anta, akwai wasu bambance-bambance a cikin bukatun sarrafa PCB. Don 1.6 jirgi mai kauri mai kauri na yau da kullun, yawancin masu kera kwamitin Gudanarwa na PCB tsakanin 0.70-0.75%, wasu masana'antu na yanki tare da karfin Warmase mai ƙarfi na iya ta da matsayin Wayar PCB zuwa 0.3%.

Ta yaya za a guji yaduwar jirgi na allo yayin masana'antu?

(1) Tsarin Semi-Retory tsakanin kowane Lay ya kamata ya zama kalma, gwargwadon yadudduka shida kewaye gabaɗaya ya zama daidai;

(2) Multi-Layer Barcelona Core Hukumar da magance takardar yakamata ayi amfani da kayayyakin mai kaya iri ɗaya;

(3) A waje da kuma B gefen layin layin ya kamata ya zama kusa da shi, lokacin da gefe yake babban jan ƙarfe, wannan halin kawai yana faruwa bayan etching warping.

Yadda za a magance yaduwa na da'ira?

1.engineer Design: Tsarin Mistery Semi-Cleing tsarin ya dace; Za a yi takardar Multilayer Multi da Semi-Worket da aka warkar da Semi-warkewa daga mai ba da kaya; Yankin jirgin sama na C / S yana da kusanci kamar yadda zai yiwu, ana iya amfani da grid mai zaman kanta.

2.Da farantin abinci kafin gurbata: Kullum 150 digiri 60 hours, ware ruwa mai ruwa a cikin farantin jiki gaba daya, ci gaba da resin resin a farantin a farantin a farantin. Takardar yin burodi a gaban buɗe, murfi na ciki da buƙatar biyu.

3.Aran nan ya kamata a biya Laminres, da hankali ya kamata a biya wa Warp da Jagora na farantin farantin: ya kamata a biya shi don bambance takardar wardp da Wemp kafin abin da aka kula da shi. Babban farantin ya kamata kuma kula da shugabanci na yaƙe-yaƙe da sata; Janar na Janar na takarda Cinaddamar da Meralian; Dogon shugabanci na tagulla na tagulla yana da dissidional; 10 yadudduka na 1oz iko lokacin farin ciki

4. Yin kauri daga cikin lamenation don kawar da danniya bayan matsi na sanyi, trimming da raw gefen.

5.Bing plate kafin hako: 150 digiri na 4 hours;

6. Shin mafi kyawun ba zai bi ta hanyar goga na injin ba, tsabtace tsabtace sunadarai; Ana amfani da gyaran musamman don hana farantin daga lanƙwasa da kuma nadawa

74. Bayan fesawa tin a kan marble mai lebur ko farantin karfe sanyaya zuwa zazzabi ko iska mai iyo yana sanyaya bayan tsaftacewa;