Gabaɗaya: idan aka kwatanta da tsarin samar da katako mai yawa da katako mai launi biyu, akwai ƙarin matakai 2, bi da bi: layin ciki da lamination.

Daki-daki: a cikin tsarin samar da farantin karfe biyu, bayan an gama yankewa, za a yi hakowa, sannan a cikin jan karfe, layin; A cikin tsarin samar da allon multilayer, bayan an gama bude kayan, ba za a yi hakowa kai tsaye ba, amma da farko yana buƙatar shiga ta cikin layi na ciki da lamination, sa'an nan kuma shiga cikin aikin hakowa don hakowa, sannan cikin tagulla da layi.

Wato, tsakanin ramukan buɗewa da hakowa, ana ƙara matakai biyu na "layin ciki" da "lamination". Abin da ke sama shine bambanci tsakanin katako mai launi da yawa da kuma samar da katako mai Layer biyu.

Na gaba, bari mu kalli abin da matakai biyu na layi na ciki da lamination suke yi

Layin ciki

Tsarin "layi" a cikin samar da faranti biyu, ciki har da matsawa na fim, nunawa, haɓakawa (idan kun manta, za ku iya komawa baya ku duba).

"Da'irar ciki" a nan ba ta da sauƙi! Bugu da ƙari, fim ɗin laminated na ciki, bayyanar ciki, ci gaba na ciki, yana kuma haɗa da pre-jiyya, ciki etching, ciki fim cire da ciki AOI.

A cikin tsarin samar da farantin karfe biyu, allon bayan an kammala ƙaddamar da jan karfe, ba tare da layin samarwa ba, kai tsaye a cikin fim ɗin dannawa, don haka babu buƙatar yin ƙarin magani mai mahimmanci. Kuma farantin karfen tagulla a nan, kawai ya fito daga aikin yankan, saman allon zai sami ƙazanta, don haka.

Kafin ciki laminate fim, shi wajibi ne don ci gaba da magani da kuma tsaftacewa, da yin amfani da sinadaran dauki, da farko cire man fetur, ruwa, ruwa mai tsabta, biyu micro-etching (cire surface tarkace), sa'an nan ruwa, sa'an nan pickling (bayan). wanka, saman zai zama oxidized, don haka yana buƙatar pickling), sa'an nan kuma ruwa, sa'an nan kuma bushe, sa'an nan kuma a cikin fim din laminate na ciki.

Fim ɗin laminate na ciki kafin magani

Bayan an danna allon, saboda ba a tono shi ba, yana kama da lebur sosai.

Fim ɗin dannawa, haɓakawa, haɓakawa, ƙayyadaddun al'amura na waɗannan hanyoyin haɗin gwiwa, an gabatar da su a cikin labarin samar da faranti biyu, a nan ba za a sake maimaita su ba.

Bayan an kammala ci gaba, wani ɓangare na tagulla za a fallasa shi, saboda yanayin waje shine tsarin fim mai kyau, ciki na ciki shine tsarin fim mara kyau. Saboda haka, bayan an gama ci gaban Layer na waje, jan ƙarfe da aka fallasa shi ne ɓangaren da ake buƙatar riƙewa, kuma jan ƙarfe da aka fallasa bayan ci gaban Layer na ciki shine ɓangaren da ake buƙatar cirewa, don haka.

Tsarin etching na ciki da na waje kuma sun bambanta, na ciki shine tsarin alkaline, a lokacin da ake yin etching, bushewar fim ɗin yana cikin, ɓangaren da ba shi da busasshen fim (taron da aka fallasa) an fara cire shi da farko. sa'an nan kuma an cire m.

An fara cire etching na waje sannan a cire shi, kuma layin yana da kariya ta wani yanki da tin ruwa.

Layin etching na fim na ciki, hagu yana da alhakin etching, dama yana da alhakin cire fim.

Bayan etching allon kewayawa, an cire jan ƙarfe da ya wuce gona da iri, kuma ba a cire sauran ɓangaren busasshen fim ɗin ba.

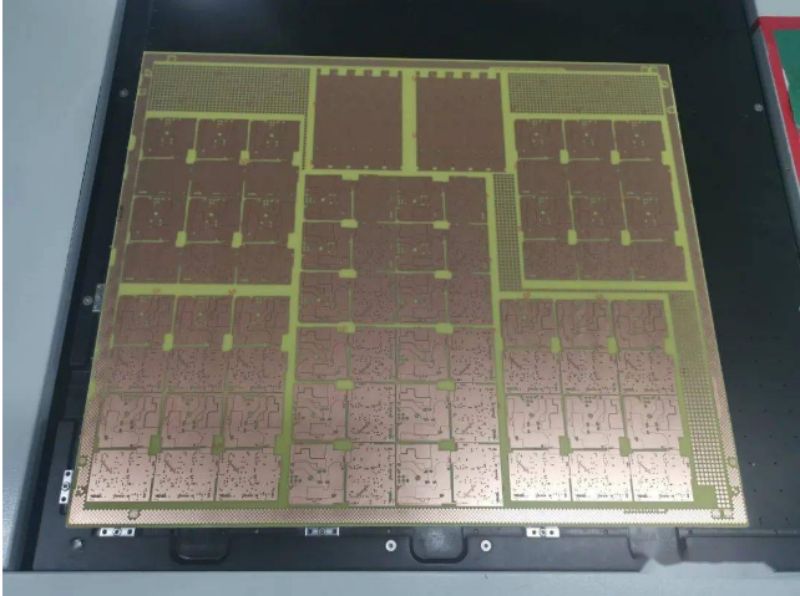

Da'irar allon bayan tsiri.

Bayan kammala fim ɗin ciki na ciki, layin da ke cikin layi ya cika gaba ɗaya, a wannan lokacin, sannan kuma ganowar gani na AOI, don sanin cewa babu matsala, zaku iya aiwatar da tsarin lamination.

Lamination:

Kawai an yi wannan allo, muna kiranta da inner core board, idan ta kasance 4 layers na allo, za a sami allo na ciki 1, idan 6 Layer na allo ne, za a sami allo na ciki 2.

Babban maƙasudin wannan tsari shine don sanya faranti na ciki da na waje a haɗe tare don samar da gaba ɗaya. Alhaki ga bonding abu, da ake kira PP, Sinanci da ake kira Semi-curing takardar, babban abun da ke ciki shi ne guduro da gilashin fiber, shi kuma zai yi wasa da ciki core jirgin da kuma m tagulla tsare rufi manufar.

Domin tabbatar da ingancin allon multilayer, mai samar da PP na Jialichuang har yanzu shine Kudancin Asiya Electronics.

Gabaɗaya, tsarin lamination ya kasu kashi huɗu cikin tsari: Browning, pre-stacking, platen, da latsawa. Na gaba, bari mu dubi cikakkun bayanai game da kowane tsari daban. A ciki core farantin bayan an kammala cire fim ne browned farko. Al’adar da’ira mai launin ruwan kasa za ta kara wani fim mai launin ruwan kasa a saman allon da’ira, wanda wani abu ne mai launin ruwan kasa, kuma samansa bai yi daidai ba, domin a samu saukin alaka da PP.

Ka'idar ta yi kama da lokacin gyaran taya keke, wurin da ya karye ya kamata a fitar da shi tare da fayil don inganta mannewar manne.

Har ila yau, tsarin Browning tsari ne na sinadarai, wanda zai bi ta hanyar pickling, wanke alkali, wanke tashoshi da yawa, bushewa, sanyaya da sauran matakai.

shiryawa

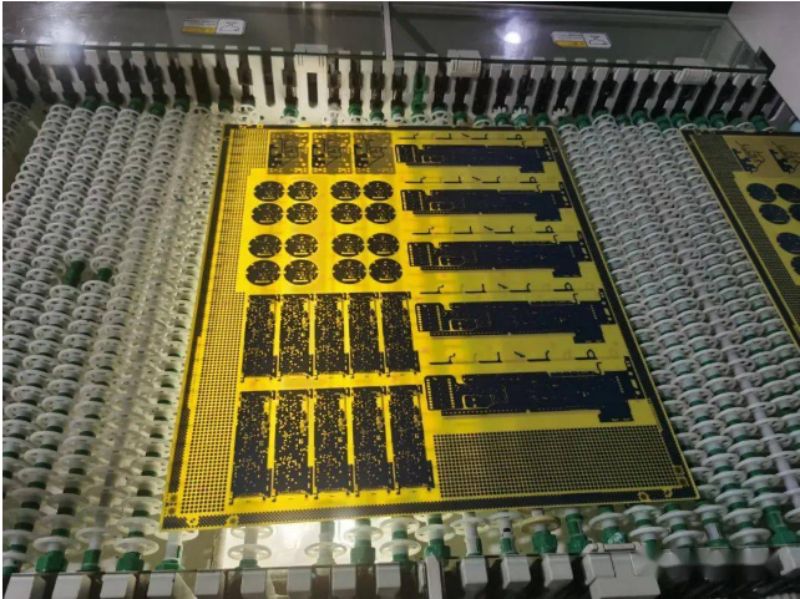

Tsarin pre-stacking, wanda aka gudanar a cikin taron bita mara ƙura, zai tara ainihin farantin da PP tare. Ana sanya PP a kowane gefen farantin ainihin. Tsawon da nisa na PP zai zama 2mm ya fi girma fiye da farantin karfe don hana gefuna mara kyau bayan dannawa.

Raft:

Babban maƙasudin farantin layi shine don ƙara ƙirar jan karfe sama da Layer na PP don shirya don layin waje na gaba. Bugu da ƙari, za a ƙara farantin karfe da takarda kraft zuwa saman Layer.lamination

Matakan farko shine shirya don lamination na ƙarshe.

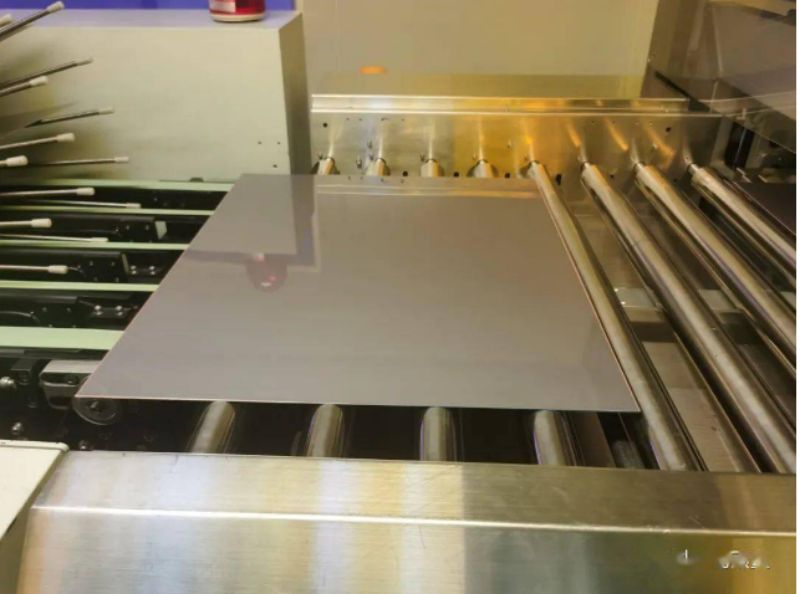

Kafin laminating, don hana warping, za a sami farantin murfin, kimanin 12mm lokacin farin ciki, karfe.

Laminating ya haɗa da matakai biyu na latsa zafi da latsa sanyi, bi da bi a cikin latsa mai zafi da latsa sanyi. Wannan hanya ce mai mahimmanci, don yin la'akari da abubuwan da suka hada da vacuum, zafin jiki, matsa lamba, lokaci, waɗannan abubuwan suna yin aiki tare da juna, don samar da allunan kewayawa masu inganci.

Alal misali, a cikin wani ɗan lokaci, yawan zafin jiki, yawan matsa lamba, da tsawon lokacin da ake buƙata, ya kamata a daidaita daidai.

Bayan ƙarshen wannan tsari, PP da farantin ciki na ciki da na waje na tagulla za a haɗa su tare.

Bayan fitowa daga cikin latsawa, ana aiwatar da rushewar atomatik, an cire farantin karfe, kuma a sake aika shi zuwa ɗakin platoon bayan an niƙa. Kamar yadda aka nuna a hoto na 11, injin yana cire farantin karfe.

Za a mayar da hukumar da'irar mai lanƙwasa zuwa wurin aikinta na hakowa na asali don yin haƙa, sauran tsarin kuma iri ɗaya ne da yadda ake kera jirgin mai Layer biyu.