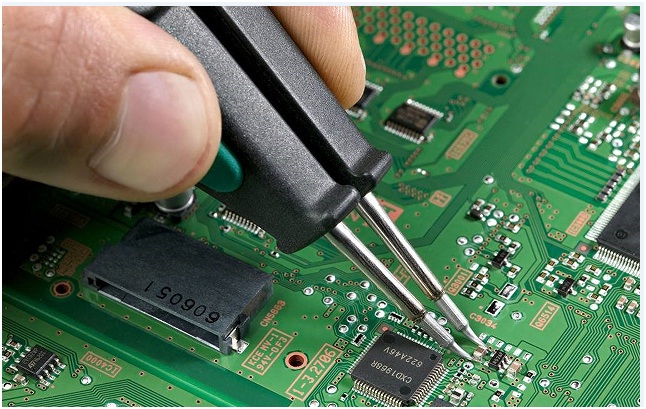

Akwai nau'ikan PCB da yawa ta hanyar buɗe ido, ana iya zaɓar masu haɓakawa daban-daban gwargwadon buƙatun aikace-aikace da buƙatun ƙira. Wadannan masu zuwa zasu yi cikakken bayani game da cire PCB da yawa ta hanyar ramuka da bambanci tsakanin PCB ta hanyar ramuka da ramuka.

一, nau'in ƙwayar cuta ta PCB ta rami

1. Matsakaicin Matsayi (PCB misali rami): yawanci a cikin ƙirar PCB, rami madauwari tare da uperturity mafi girma fiye da ko daidai da 0.4mm ana kiranta da daidaitaccen aperture. Wannan aperture ana amfani dashi don amintar da kwamitin PCB da kayan aikin PIN.

2. Micro rami mai sakewa: micro rami aperture yana nufin rami madauwari tare da diamita na ƙasa da 0.4mm. Tare da kara karamin kayan lantarki na lantarki, akwai wata babbar buƙata ga ƙirar PCB, don haka micropore ciperttures sannu a hankali. Aikace-aikace na karinssi sun haɗa da ƙananan na'urorin lantarki kamar kwamfyutocin kwamfyutoci da wayoyin hannu.

3. Rami mai dauke da rami): Ramin ramuka suna da alaƙa ta hanyar ramuka, yawanci ana amfani da su don shigar da kayan haɗin tare da abubuwan da aka kera su, kamar masu haɗin kai ko zafi.

, Bambanci tsakanin PCB ta rami kuma cikin rami

PCB ta rami kuma cikin rami sun bambanta da amfani da kwamitin PCB, yawancin bambance-bambance ne masu zuwa:

1. PCB Designiyar niyya: ramuka na PCB suna da gangan ramuka a cikin ƙirar, kuma za a sarrafa su don haɗa aƙalla biyu na PCB yadudduka. Ta hanyar ramuka an tsara su don haɗa takamaiman Layer ko kayan aikin, kuma an ƙaddara wurinsu ta hanyar ƙirar ƙira.

2, haɗin sigina (Haɗin sigina): PCB ta rami alama ita ce PIN mai siginar daga wani Layer zuwa wani Layer don cimma nasarar watsa siginar. Ta hanyar ramuka ana amfani da gara a gyara allon PCB da abubuwan haɗin gwiwa da samar da tallafi na inji.

3. Masana'antu mai sarrafa: Za a bi da ramuka na PCB tare da kayan aikin musamman da kayan aiki yayin aiwatar da aikin, yawanci ta hanyar karuwa don ƙara yawan zartar da lantarki. Da rami ya kasance mai sauki, yawanci yana buƙatar yin makama rami a cikin daidai wurin.

4. Tallafin Tallafi: Kasancewar ramuka na PCB na iya haɓaka kwanciyar hankali na PCB da kuma righiyar jirgin PCB, kuma kunna aiki mai tallafawa. Kodayake rami na rami na iya kara wani matakin tsayayye, babban dalilin shi ne don samar da gyarawa da haɗi.

A taƙaice, kawar da PCB ta rami ta hanyar rami mai daidaitaccen kaya, crassure da rami mai ɗaukar hoto. Bambanci tsakanin PCB ta hanyar ramuka kuma ta hanyar ramuka a cikin niyyar ƙira, haɗin sigina, haɗin sigina da tallafi na tsari. An iya haduwa da nau'ikan ƙirar PCB da Majalisar Deta ta zaɓi nau'ikan nau'ikan haɓakawa da kuma amfani da dacewa ta hanyar ramuka ko ta hanyar ramuka.