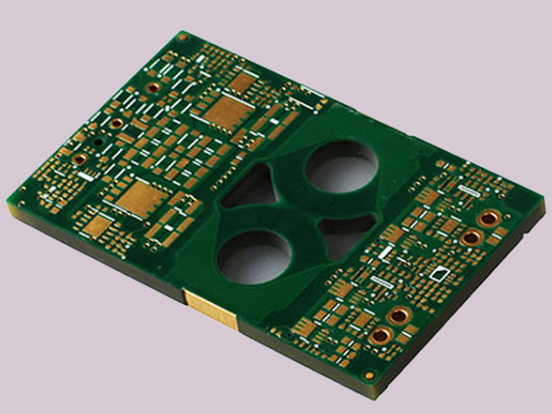

GabatarwaMai kauri mai kauri mai kauriHanyar sarrafa

(1) shiri na shirya da magani mara iyaka

Babban manufar kauri na jan karfe shine don tabbatar da cewa akwai wani lokacin farin ciki isassan iska a cikin rami don tabbatar da cewa darajar tsayayya tana cikin kewayon da ake buƙata. A matsayin fulogin ciki, shi ne don gyara matsayin kuma tabbatar da ƙarfin haɗin; A matsayina na wani yanki-da aka ɗora, ana amfani da wasu ramuka kamar yadda ta hanyar ramuka, wanda ke taka rawa wajen gudanar da wutar lantarki a garesu.

(2) abubuwan dubawa

1. Galibi suna bincika ingancin ƙarfe na rami, kuma tabbatar da cewa babu wani wuce haddi, burr, rami baki, rami, da sauransu a cikin rami;

2. Dubawa ko akwai datti da sauran hanyoyin da ke kan saman substrate;

3. Duba lamba, lambar zane, takaddar tsari da aiwatar da bayanin yadda ake substrate;

4. Gano matsayin hawa, abubuwan hawa da kuma wani yanki mai rufi wanda tanki na iya ɗauka;

5. Yakamata a samar da yankin da kuma tsari na tsari ya kamata a bayyane don tabbatar da kwanciyar hankali da kuma yiwuwar aiwatar da sigogin aikin.

6. Tsaftacewa da kuma shirye-shiryen warwarewa sassa, magani na farko don yin maganin da aiki;

7 4. Kayyade ko abun da ke ciki na ruwan wanka ya cancanci kuma saman farantin lantarki; Idan an shigar da akwatin gidan spherical a cikin shafi, kuma za a sake amfani da amfani;

8. Bincika madaidaicin bangarorin lambobin sadarwa da kewayon ƙarfin lantarki da na yanzu.

(3) ingancin kula da karfe mai kauri

1. Yi daidai da yankin da aka sanya shi kuma yana nufin tasirin ainihin tsari a yanzu, daidai canji na yanzu a cikin tsarin da ba za a iya amfani da su ba;

2. Kafin electroating, da farko yi amfani da kwamitin debugging don shirya gwajin, saboda wanka yana cikin yanayi mai aiki;

3 4. Eterayyade jagorar kwarara na jimlar na yanzu, sannan ka tantance tsari na faranti mai ratsi. Bisa manufa, ya kamata a yi amfani da shi daga nesa zuwa kusa; don tabbatar da daidaituwa na rarraba halin yanzu a kowane farfajiya;

4. Don tabbatar da daidaituwa na shafi a cikin rami da daidaito na kauri daga cikin shafi, ban da matakai na fasaha na motsa da tace, shi ma wajibi ne don amfani da halin yanzu;

5. A kai a kai ka lura da canje-canje na yanzu yayin aiwatar da leleplating don tabbatar da amincin da kwanciyar hankali na kimar na yanzu;

6. Duba ko kauri daga cikin murfin jan karfe Layer na ramin ya hadu da bukatun fasaha.

(4) tsarin jan karfe

A kan aiwatar da kauri na jan karfe, sigogin aikin dole ne a saɓa a kullun saboda dalilai na musamman da na manufofin. Don yin kyakkyawan aikin da aka kwantar da hankalin sutturar da jan ƙarfe, dole ne a yi waɗannan bangarorin:

1. A cewar darajar yankin da komputa ta lissafta ta hanyar komputa, hade da kwarewar da aka tara a cikin ainihin samar da ingantacciyar hanya;

2. A cewar ƙimar lissafin yanzu, don tabbatar da amincin kwanon rufi a cikin rami, shi ne, instruh na yanzu, sannan komawa zuwa ainihin darajar a cikin ɗan gajeren lokaci;

3. Lokacin da ƙaddarar katako ta kai minti 5, cire subes don lura da ko murfin ciki na ramin yana da ƙarfe na da ƙarfe na da ƙarfe.

4. Dole ne a kiyaye wani nesa tsakanin substrate da substrate;

5. Lokacin da kuka daurin ƙarfe na ƙarfe mai kauri ya kai ga lokacin da ake buƙata na da ake buƙata, dole ne a kiyaye wani adadin na yanzu lokacin cire substrate ba zai zama mai duhu ko duhu ba.

Matakan kariya:

1. Duba takardun aiwatar, karanta ka'idojin aikin kuma ka saba da alamar mashin na substrate;

2. Bincika farfajiya na subrate don karce, bayyanar, sassan tagulla na taguwa, da sauransu.;

3. Aiwatar da aikin gwaji gwargwadon faifai mai sarrafa injiniya, aiwatar da bincike na farko na farko, sannan aiwatar da dukkanin aikin bayan saduwa da bukatun fasaha;

4. Shirya kayan aikin aunawa da sauran kayan aikin da aka yi amfani da su don saka idanu akan girman geometricons na substrate;

5. A cewar albarkatun kayan masarufi na sarrafa substrate, zaɓi kayan aikin injin da ya dace da ya dace (Milling abun ciki).

(5) kulawa mai inganci

1. Daidai ne a kan tsarin binciken labarin farko don tabbatar da cewa girman samfurin ya sadu da bukatun ƙira;

2. A cewar albarkatun ƙasa na allunan da'irar, mai hankali zaɓi sigogin ƙirar milling;

3. Lokacin da gyara matsayin kwamitin da'irar, a hankali matsa shi don in guji lalacewar mayafin mai siyarwa;

4. Don tabbatar da daidaito na girman fitowar waje na substrate, dole ne a sarrafa daidaito mai mahimmanci;

5. Lokacin da aka rarraba rarrabuwa da tara hankali ya kamata a biya su da padding din tushe na substrate don gujewa lalacewar murfin murfin a farfajiya na jirgin.