A cikin tsarin ƙirar PCB, layout na kayan aikin yana da mahimmanci, wanda ke ƙayyade na m da yawa na allon da aka buga, kuma yana da wani tasiri a kan amincin duka.

Kyakkyawan hukumar da'ira, ban da tabbatar da ka'idar aikin, har ma don la'akari da EMC, emprostatic Matsakaicin Matsaloli, amma kuma don la'akari da tsarin na inji, babban kayan aiki na lantarki, mafi girman iko Power Trist Matsaloli.

Bukatun Dokoki na PCB

1, karanta daftarin rubutu, saduwa da tsarin musamman, module na musamman da sauran buƙatun layout.

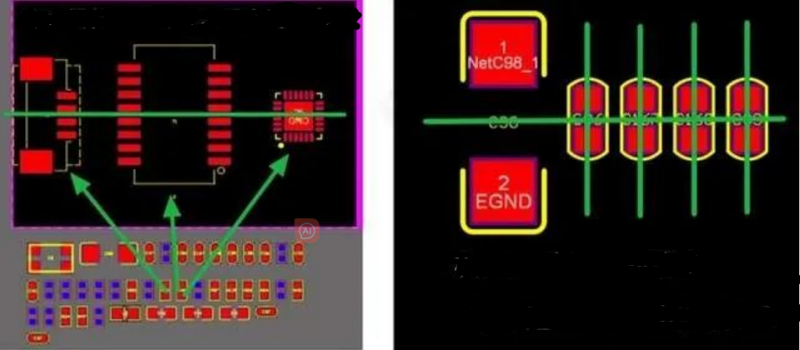

2, saita ma'aunin yanki zuwa 25mil, za a iya sāɗa ta hanyar grid ma'anar, daidai ba; Yanayin jeri yana da yawa kafin ƙarami (manyan na'urori da manyan na'urori sun fara aiki), kuma yanayin juyi shine cibiyar, kamar yadda aka nuna a cikin wannan adadi

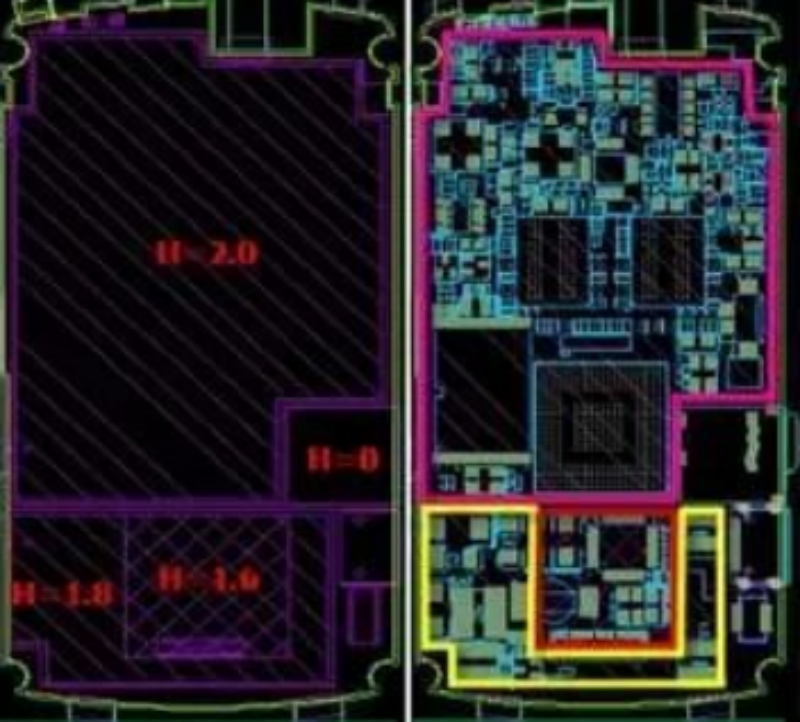

3, saduwa da iyakar tsallakancin yanki, tsari da kuma shimfidar wuri na musamman, abubuwan da aka hana ba su da bukatun yankin.

Hoto 1 (hagu) a ƙasa: Buƙatar iyakance mai tsayi, alama a sarari a cikin Layer Layer ko alamar alama, wanda ya dace daga baya-dubawa;

(2) Kafin layout, saita da aka hana yankin, sai ga na'urar ta zama 5mm nesa daga gefen allon, sai dai idan ƙirar na musamman ko zane mai zuwa;

Me layout na tsarin da na'urori na musamman za su iya zama daidai da daidaitawa ta daidaitawa ko ta daidaita firam na waje ko layin tsakiya na kayan aikin.

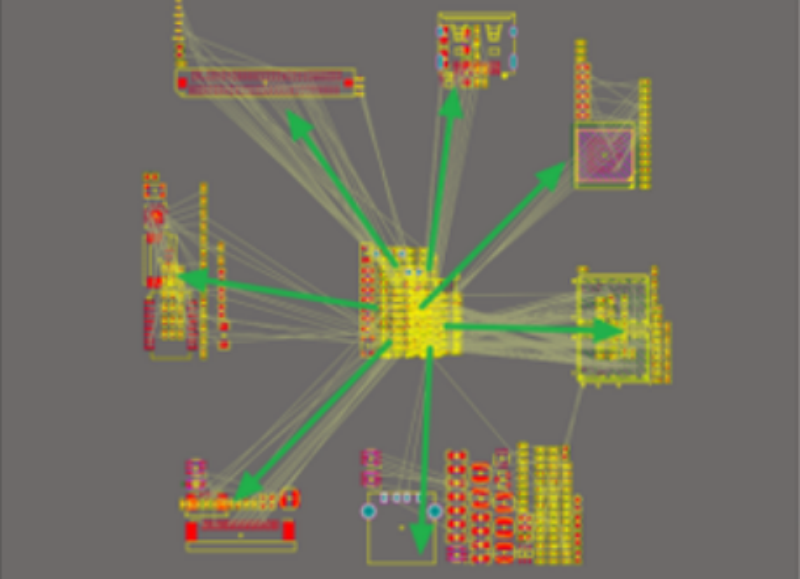

4, layout ya kamata ya sami pre-layout farko, kar a iya yin amfani da bincike na yau da kullun, kimanin kimanin siginar siginar a cikin PCB da girman kewayon aiki. Zana layin auxilary line 40mil, kuma ya kimanta ka'idodin lafazin tsakanin kayayyaki da kayayyaki a cikin ayyukan da ke sama, kamar yadda aka nuna a cikin adadi a ƙasa.

5, layout yana buƙatar la'akari da tashar da ta bar layin wutar lantarki, bai kamata ya zama da yawa sosai ba, ta hanyar shirin gano inda wutar take da ƙarfi, ta hanyar tsage itacen

6, kayan aikin theryral (kamar masu ɗaukar hoto na lantarki, crystal Oscilators) shimfidar kayayyaki da sauran kayan wutar lantarki da sauran su a cikin iska mai ƙarfi

7, don saduwa da bambancin yanayi mai mahimmanci, ma'auni dukkanin labul din dukiyar, duk kwamitin ajiyar tashar Wiring

Maƙasudin sigina da manyan sigina suna rabuwa da sigina masu rauni na ƙananan igiyoyi da ƙananan voltages. Abubuwan da wutar lantarki masu ƙarfin ƙarfin lantarki suna lalata a cikin dukkan yadudduka ba tare da ƙarin tagulla ba. An bincika 'yar iska tsakanin matattarar wutar lantarki a cikin tebur daidai

Siginar analog ta rabu da siginar dijital tare da nisa na 20mil, da analog da analog da an tsara su a cikin bukatun a cikin tsarin m

An raba siginar mita mai yawa daga siginar mitar, nisan rabuwa shine aƙalla 3mm, kuma ba za'a iya tabbatar da layout giciye ba

Tsarin na'urori masu samfuran siginar kamar su kayatarwa da direban Crystal ya kamata ya yi nisa da shimfidar gidaje, ba a gefen jirgin ba, kuma aƙalla 10mm nesa daga gefen hukumar. Ya kamata a sanya kresstal da Crystal

Tsarin da'irar guda ɗaya suna ɗaukar "daidaitaccen" daidaitaccen tsari (kai tsaye) don saduwa da daidaiton siginar

Bayan ƙirar PCB, dole ne mu yi bincike da bincike don yin samarwa mafi kyau.