Dangane da zane mai da'irar ci gaba, ana iya yin kwaikwayon kwaikwayo kuma PCB za a iya tsara ta hanyar fitar da fayil / rawar soja. Duk abin da ƙira, injiniyoyi suna buƙatar fahimtar daidai yadda cirir take (da abubuwan lantarki) ya kamata a shimfiɗa su da yadda suke aiki. Don injiniyoyin lantarki, suna samun kayan aikin software na dama na PCB na iya zama aiki mai kyau. Kayan aikin software waɗanda suke aiki da kyau don aikin PCB ɗaya na iya aiki da kyau ga wasu. Injiniya na son kayan aikin zane waɗanda suke da hankali, suna ɗauke da abubuwa masu amfani, suna da tabbaci sosai don iyakance cikin haɗari, kuma suna da ɗakin karatu mai ƙarfi wanda ya dace da su don ayyuka da yawa.

Matsalar kayan aiki

Don ayyukan IOT, hadewar hadewa suna da mahimmanci ga aiki da aminci, kuma hadewar illolin da ba masu zane-zane ba don nazarin ma'amala tsakanin abubuwan lantarki da na injiniyoyi. Musamman, kamar yadda masu girma dabam ke ci gaba da raguwa, dulakin lantarki akan kwaya yana ƙara ƙara m. A lokaci guda, buƙatun aiki yana tashi. Don cimma nasarar aiwatar da aikin ƙirar, amsar zazzabi, halayyar kayan aikin lantarki a kan allo, kuma kula da kanada suna da mahimmanci ga ayyukan.

Dole ne a ware PCB don tabbatar da kariya. Short da'irori an hana su kare hanyoyin tagulla da aka sanya a kan allo don ƙirƙirar tsarin lantarki. Idan aka kwatanta su da madadin ƙananan farashi kamar su na rennt na runtse takarda (SRBP, FR-2), FR-4 ya fi dacewa a matsayin madadin shi da substrate, da kuma gaskiyar cewa yana ɗaukar ƙasa da sauran kayan da sauran kayan. Ana amfani da FR-4 a cikin gine-gine masu tsayi da kuma kayan aikin masana'antu. Ya dace tare da rufin mai tsayi mai tsayi (matsanancin injin-da yawa ko UHV).

Koyaya, FR-4 azaman Substrate yana fuskantar wurare da yawa, wanda tushe daga maganin da aka yi amfani da shi wajen samarwa. Musamman, kayan yana yiwuwa ga samuwar ƙwallon ƙafa (kumfa) da stushbles (logritudigs na tsawon lokaci), da kuma nakasar fiber na gilashin. Waɗannan lahani na iya haifar da ƙarfinsu masu rarrabuwar hankali da kuma inganta aikin wallon na PCB. Sabon tsarin gilashin epoxy yana magance waɗannan matsalolin.

Sauran kayan da ake amfani da su sun hada da polyimide / gilashin gilashi (wanda ke tallafawa mafi girma yanayin zafi kuma yana da wahala) da kumapton (da suka dace da aikace-aikacen kamar su. Abubuwan da za a yi la'akari da lokacin da zaɓar kayan aiki (substrates) sun haɗa da madaidaitan fadada yanayin fadada (CTE), halin canjin yanayin zafin jiki (tg), hali na yanayin zafi (tg), halin da aka yiwa zafi.

Military/aerospace PCBS require special design considerations based on layout specifications and 100% Design for Test (DFT) coverage. Hanyoyin mil-std-883 da hanyoyin gwada na'urorin gwaji sun dace da matakan horo da aminci don tabbatar da daidaitattun matakan inganci da aminci a cikin tsarin. Daban-daban aikace-aikace na irin waɗannan na'urori.

Baya ga haduwa da ka'idodi daban-daban, ƙirar tsarin sarrafa kayan aiki dole ne ya bi jerin dokoki, kamar gwajin kayan lantarki da lantarki don tattara kayan kewaye. Tasirin crosstalk na iya tsoma baki tare da amincin abin hawa. Don rage girman waɗannan tasirin, masu zanen PCB dole ne su faɗi nesa tsakanin layin alamar da kuma layin wutar lantarki. Ana amfani da ƙira da daidaitattun kayan aikin software wanda ke buƙatar ƙarin hanyoyin ta atomatik don haduwa da iyakancewar tsangwama da yanayin zafi don guje wa kan aiwatar da tsarin.

Bayanan kula:

Tsangwama daga da'ira kanta ba barazana bane ga ingancin siginar. An jefa PCB a cikin motar da aka jefa tare da amo, wanda ke hulɗa tare da jiki a cikin hanyoyin rikitarwa na haifar da rashin yarda a cikin da'irar. Voltage spikes da hawa da sauka ya haifar da tsarin kwastomomi na sarrafa kansa na iya tura abubuwan da ke kan abubuwan da suka fi dacewa da yarda da jikokinsu.

Software

Kayan aikin PCB na yau dole ne su sami haɗin haɗi na aiki da yawa don biyan bukatun masu zanen kaya. Zabi kayan aikin dama ya kamata ya zama cikakken la'akari a cikin ƙirar PCB kuma bai kamata a manta da shi ba. Kayayyaki daga zane-zane mai mashawarta, tsarin kayan orcad, da kuma Altium suna cikin kayan aikin PCB na yau.

Mai tsara altium

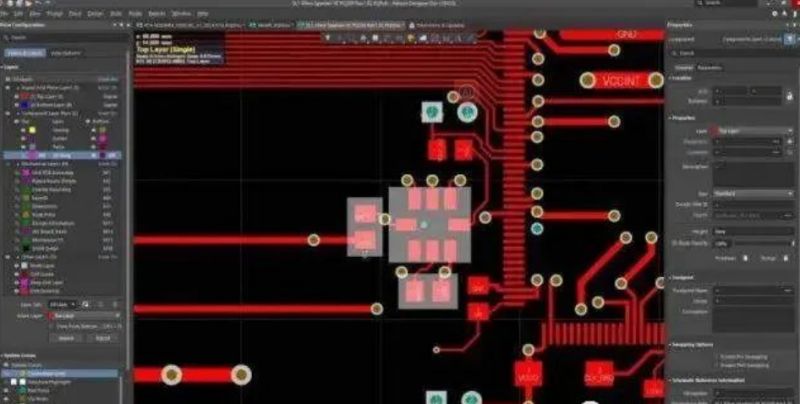

Dakin Altium yana daya daga cikin kayan zane na PCB na PCB a kasuwa a yau. Tare da aikin wiring na atomatik, goyan baya don daidaitawa tsawon layi da samfurin 3D. Designestaƙƙarfan ayyuka na Altium sun haɗa da kayan aikin ƙirar ƙirar ƙirar, daga kwarewar tsari zuwa HDL har ma da bincike, bincike na siginar, da FPGA, da FPGA na haɓaka

Graphic zane 'PCB layout Platpater yana ba da bayani game da manyan ƙalubalen da masu zanen zamani: aski, aiki - da kuma sake amfani da shawarar da aka tsara; Ingantacciyar hanyar motsa jiki a cikin mawuyaci da hadaddun tabbaci; Da kuma hana lantarki. Babban fasalin dandamali da mahimmin mahimmanci don masana'antar na'ura mai ba da na'uri mai amfani da yanar gizo, wanda ba a ba da na'urori da ke tattare da shi ba, amma a cikin lokaci mai yawa.

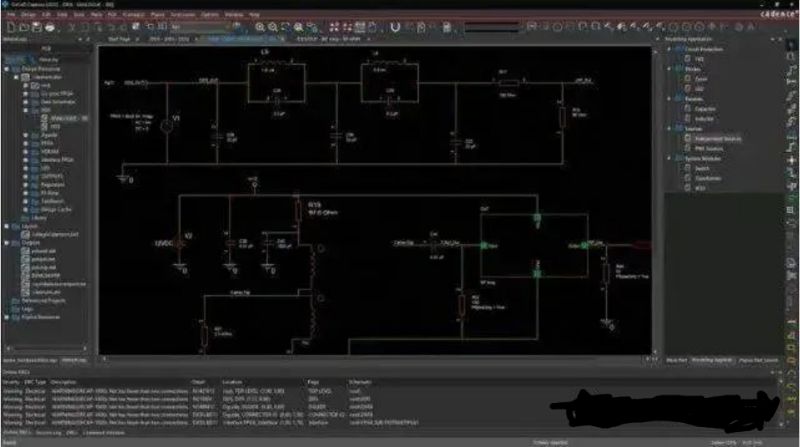

Orcad PCB Edita

Orcad PCB Editor shine yanayin zama mai ma'amala don ƙirar hukumar a kowane matakin fasaha, daga sauki ga hadaddun. Saboda sculility na gaske ga Carcence Allasscallallon Kamfanin Kamfanin PCB mai zanen kwastomomi na PCB na PCB, da sauran EDungiyar ta PCB tana tallafawa haɓaka ƙirar zane-zane kuma da sauransu) yayin da ake riƙe da tsarin zane-zane iri ɗaya

Fayil ɗin gerber

Ana amfani da ingantaccen tsarin fayil ɗin Gerber don isar da bayanan zane don samarwar PCB. A hanyoyi da yawa, Gerber ya yi kama da PDFs a cikin lantarki; Wani karamin tsarin fayil ne wanda aka rubuta a cikin yaren sarrafa inji. Waɗannan fayilolin ana samar dasu ta hanyar software na Software ɗinsu kuma an aika zuwa masana'antar PCB zuwa software na Cam.

A amince inganta tsarin lantarki a cikin motoci da sauran tsarin hadaddun yana gabatar da mahimman la'akari ga duka kayan aiki da software. Injiniya na da niyyar rage yawan ƙimar ƙira da lokacin ci gaba, wanda ke da fa'idodi masu mahimmanci ga masu zanen kaya waɗanda suke aiwatar da aiki.