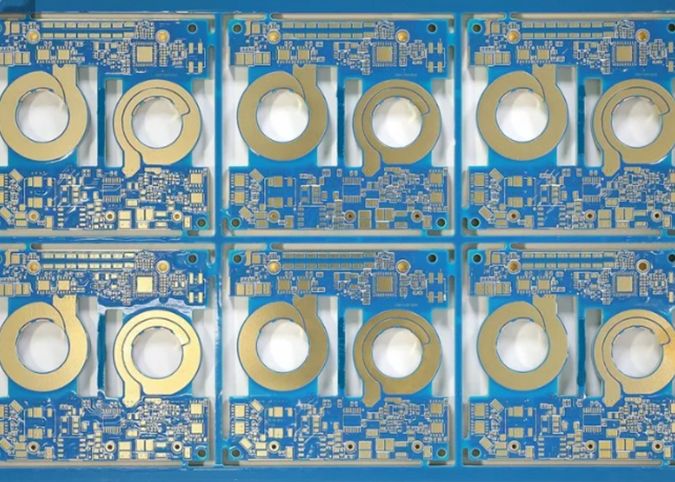

Kayayyakin da'ira sun dogara da ingantattun madugu da kayan wuta don haɗa hadaddun kayan aikin zamani zuwa juna don ingantaccen aiki. Koyaya, a matsayin masu gudanarwa, waɗannan na'urorin tagulla na PCB, ko DC ko mm Wave PCB allunan, suna buƙatar kariyar tsufa da iskar shaka. Ana iya samun wannan kariyar a cikin nau'i na electrolysis da suturar nutsewa. Sau da yawa suna ba da nau'i daban-daban na ƙarfin walda, ta yadda ko da da ƙananan sassa, ƙananan ɗorawa (SMT), da dai sauransu, ana iya samun cikakkiyar wurin walda. Akwai nau'i-nau'i iri-iri da jiyya na saman da za a iya amfani da su akan masu kula da tagulla na PCB a cikin masana'antu. Fahimtar da halaye da kuma dangi halin kaka na kowane shafi da surface jiyya taimaka mana yin dace zabi don cimma mafi girma yi da kuma mafi tsawo sabis rayuwa na PCB allon.

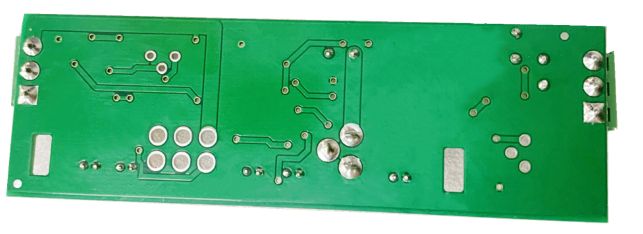

Zaɓin gamawar ƙarshe na PCB ba tsari bane mai sauƙi wanda ke buƙatar la'akari da manufar PCB da yanayin aiki. Halin da ake ciki a halin yanzu zuwa cunkoso, ƙarami, manyan hanyoyin PCB masu sauri da ƙarami, sirara, PCBS mai girma yana haifar da ƙalubale ga masana'antun PCB da yawa. PCB da'irori ana kerarre ta laminates na daban-daban na karfe tsare nauyi da kuma kauri da aka kawo wa PCB masana'antun da kayan masana'antun, irin su Rogers, wanda sa'an nan sarrafa wadannan laminates zuwa daban-daban na PCBS don amfani a Electronics. Ba tare da wani nau'i na kariya ta saman ba, masu gudanarwa a kan kewaye za su yi oxidize yayin ajiya. Maganin saman madugu yana aiki azaman shamaki da ke raba madugu da mahalli. Ba wai kawai yana kare PCB madugu daga hadawan abu da iskar shaka ba, har ma yana ba da hanyar sadarwa don da'irori da abubuwan walda, gami da haɗin kai na haɗaɗɗun da'irori (ics).

Zaɓi saman PCB mai dacewa

Maganin da ya dace ya kamata ya taimaka don saduwa da aikace-aikacen da'irar PCB da kuma tsarin masana'antu. Farashin ya bambanta saboda farashin kayan daban-daban, matakai daban-daban da nau'ikan gamawa da ake buƙata. Wasu jiyya na saman suna ba da izini ga babban abin dogaro da babban keɓewar da'irori masu yawa, yayin da wasu na iya haifar da gada maras buƙata tsakanin masu gudanarwa. Wasu jiyya na saman sun haɗu da buƙatun soja da sararin samaniya, kamar zafin jiki, girgiza da girgiza, yayin da wasu ba su da garantin babban amincin da ake buƙata don waɗannan aikace-aikacen. Da aka jera a ƙasa akwai wasu jiyya na PCB waɗanda za a iya amfani da su a cikin da'irori waɗanda suka kama daga da'irori na DC zuwa igiyoyin igiyoyin millimita da da'irori mai saurin dijital (HSD):

●ENIG

●KISHI

●HASL

● Azurfa nutsewa

●Tsarin nutsewa

●LF HASL

●OSP

● Electrolytic wuya zinariya

● Zinariya mai laushi da aka haɗa da lantarki

1.ENIG

ENIG, kuma aka sani da sinadarai nickel-zinariya tsari, ana amfani da ko'ina a saman jiyya na PCB hukumar gudanarwa. Wannan tsari ne mai sauƙi mai sauƙi wanda ke samar da siriri na zinari mai walƙiya a saman Layer nickel akan saman madubin, wanda ke haifar da fili mai faɗi tare da kyakkyawar ikon walda ko da a cikin da'irori masu yawa. Kodayake tsarin ENIG yana tabbatar da amincin ta hanyar-rami electroplating (PTH), yana kuma ƙara asarar mai gudanarwa a babban mita. Wannan tsari yana da tsawon rayuwar ajiya, daidai da ka'idodin RoHS, daga masana'antar kera da'ira, zuwa tsarin haɗakarwa, da kuma samfurin ƙarshe, yana iya ba da kariya ta dogon lokaci ga masu gudanar da PCB, don haka yawancin masu haɓaka PCB suna zaɓar. na kowa surface jiyya.

2. ENEPIG

ENEPIG haɓakawa ne na tsarin ENIG ta hanyar ƙara ƙaramin palladium na bakin ciki tsakanin sinadari mai nickel da Layer plating na zinari. Layer na palladium yana kare Layer nickel (wanda ke kare madubin jan karfe), yayin da zinariyar zinariya yana kare palladium da nickel. Wannan saman jiyya shi ne manufa domin bonding na'urorin zuwa PCB jagororin kuma zai iya rike mahara reflow tafiyar matakai. Kamar ENIG, ENEPIG ya dace da RoHS.

3.Azurfa nutsewa

Chemical silver sedimentation ne kuma ba electrolytic sinadaran tsari a cikin abin da PCB ne gaba daya immersed a cikin wani bayani na azurfa ions zuwa daure azurfa a saman na jan karfe. Sakamakon da aka samu ya fi daidaito da daidaito fiye da ENIG, amma ya rasa kariya da dorewa da Layer nickel ke bayarwa a cikin ENIG. Kodayake tsarin kula da saman sa ya fi sauƙi kuma mafi tsada fiye da ENIG, bai dace da adana dogon lokaci tare da masana'antun kewaye ba.

4.Immersion Tin

Hanyoyin shigar da sinadarai na sinadarai suna samar da murfin tin na bakin ciki a saman madubi ta hanyar matakai masu yawa wanda ya haɗa da tsaftacewa, micro-etching, prepreg acid bayani, nutsar da maganin leaching maras amfani da lantarki, da tsaftacewa ta ƙarshe. Maganin tin na iya ba da kariya mai kyau ga tagulla da masu gudanarwa, yana ba da gudummawa ga ƙarancin asarar da'irori na HSD. Abin baƙin ciki, da sinadari sunk ba daya daga cikin mafi dadewa da dawwama na madugu jiyya saboda tasirin da tin yana da tagulla na tsawon lokaci (watau yaduwar karfe daya zuwa wani yana rage tsawon lokaci na aikin da'ira). Kamar azurfar sinadari, tin sinadari ba shi da gubar, tsari na RoHs.

5.OSP

Fim ɗin kariya na waldawa na halitta (OSP) wani abu ne mai kariya mara ƙarfe wanda aka lulluɓe da maganin tushen ruwa. Wannan ƙare kuma ya dace da RoHS. Koyaya, wannan jiyya ta saman ba ta da tsawon rairayi kuma an fi amfani da ita kafin a haɗa da'ira da abubuwan haɗin zuwa PCB. Kwanan nan, sababbin membranes na OSP sun bayyana a kasuwa, waɗanda aka yi imanin za su iya ba da kariya ta dindindin ga masu gudanarwa.

6.Electrolytic wuya zinariya

Maganin gwal mai wuya wani tsari ne na electrolytic wanda ya dace da tsarin RoHS, wanda zai iya kare PCB da mai kula da jan karfe daga oxidation na dogon lokaci. Duk da haka, saboda tsadar kayan aiki, shi ma yana ɗaya daga cikin mafi tsadar kayan da ake amfani da su. Hakanan yana da ƙarancin walƙiya, ƙarancin walƙiya don haɗawa da jiyya mai laushi mai laushi, kuma yana da yarda da RoHS kuma yana iya samar da kyakkyawan saman na'urar don haɗawa da jagorar PCB.