The via ne daya daga cikin muhimman sassa na Multi-Layer PCB, da kuma kudin na hakowa yawanci lissafin ga 30% zuwa 40% na kudin PCB hukumar. A taƙaice, kowane rami a kan PCB ana iya kiransa via.

Babban manufar ta hanyar:

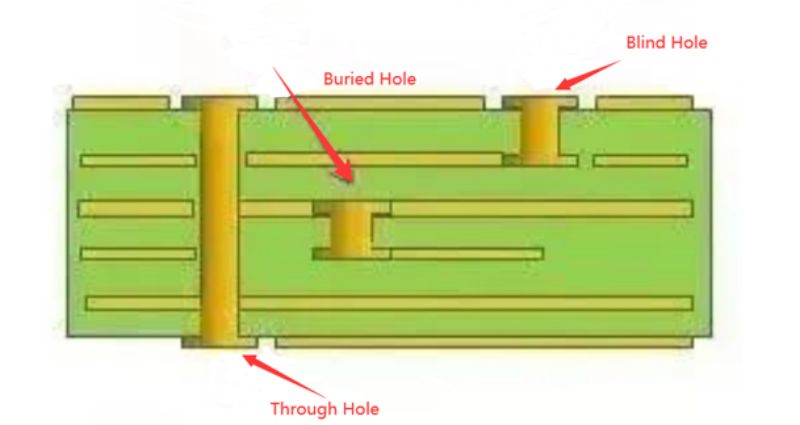

Daga mahangar aiki, ana iya raba hanyar zuwa kashi biyu: ana amfani da ɗayan azaman haɗin wutar lantarki tsakanin layuka, ɗayan kuma ana amfani da shi azaman gyarawa ko sakawa na'urar. Idan daga tsarin, gabaɗaya waɗannan ramukan sun kasu kashi uku, wato ramukan makafi, ramukan binne da ramuka.

Ana samun ramukan makafi a saman saman da kasa na allon da aka buga kuma suna da takamaiman zurfin haɗin da'irar saman da kewayen ciki da ke ƙasa, kuma zurfin ramukan yawanci baya wuce ƙayyadaddun rabo (budewa).

Ramin da aka binne yana nufin ramin haɗin da ke cikin layin ciki na allon da aka buga, wanda baya wuce saman allon. Nau'o'in ramuka guda biyu da ke sama suna cikin rufin ciki na allon kewayawa, wanda aka kammala ta hanyar gyare-gyaren ramuka kafin lamination, kuma yawancin yadudduka na ciki na iya haɗuwa yayin samuwar ramin.

Nau'i na uku ana kiransa ta-ramuka, wanda ke ratsa ta cikin dukkan allon da'ira kuma ana iya amfani da shi don cimma haɗin kai na ciki ko azaman ramukan saka ramuka don abubuwan haɗin gwiwa. Domin ta hanyar rami ya fi sauƙi don cimmawa a cikin tsari kuma farashin ya ragu, yawancin allon da'irar da aka buga suna amfani da shi, maimakon sauran biyu ta ramuka. Ramukan da ke gaba, ba tare da umarni na musamman ba, ana ɗaukar su azaman ta ramuka.

A mahangar zayyana, na’ura mai suna via ya kunshi sassa biyu ne, daya shi ne tsakiyar ramin hakowa, dayan kuma shi ne wurin walda da ke kusa da ramin hakowa. Girman waɗannan sassa biyu yana ƙayyade girman ta hanyar.

Babu shakka, a cikin tsayin daka, ƙirar PCB mai girma, masu zanen kaya koyaushe suna son ramin ƙarami ne sosai, don haka ana iya barin sararin wiring, ƙari, ƙarami ta hanyar, ƙarfin ikonsa na parasitic yana ƙarami, mafi dacewa. don manyan da'irori masu sauri.

Duk da haka, raguwa ta hanyar girman kuma yana haifar da karuwar farashi, kuma girman ramin ba za a iya rage shi ba har abada, an iyakance shi ta hanyar hakowa da fasahar lantarki: ƙananan ramin, tsawon lokacin hakowa yana da sauƙi. shine a karkace daga tsakiya; Lokacin da zurfin rami ya fi sau 6 diamita na ramin, ba shi yiwuwa a tabbatar da cewa bangon ramin yana iya zama daidai da jan karfe.

Misali, idan kauri (ta zurfin rami) na allon PCB mai Layer 6 na al'ada shine 50Mil, to mafi ƙarancin diamita na hakowa wanda masana'antun PCB zasu iya bayarwa a ƙarƙashin yanayin al'ada zai iya kaiwa 8Mil kawai. Tare da haɓaka fasahar hakowa ta Laser, girman hakowa kuma na iya zama ƙarami da ƙarami, kuma diamita na ramin gabaɗaya bai kai ko daidai da 6Mils ba, ana kiran mu microholes.

Ana amfani da microholes sau da yawa a cikin ƙirar HDI (tsarin haɗin haɗin haɗin kai mai girma), kuma fasahar microhole na iya ba da damar ramin da za a haƙa shi kai tsaye a kan kushin, wanda ke haɓaka aikin kewayawa sosai kuma yana adana sararin waya. Wayar tana bayyana azaman ƙarshen katsewa kan layin watsawa, yana haifar da tunanin siginar. Gabaɗaya, daidaitaccen ramin rami yana kusan 12% ƙasa da layin watsawa, alal misali, ƙarancin layin watsawa ohms 50 zai ragu da 6 ohms lokacin da ya wuce ta cikin rami (musamman da girman ta hanyar, kaurin farantin kuma yana da alaƙa, ba cikakken raguwa ba).

Koyaya, tunanin da aka samu ta hanyar katsewar impedance ta haƙiƙa ƙanƙanta ne, kuma ƙimar kwatancensa shine kawai:

(44-50)/(44 + 50) = 0.06

Matsalolin da ke tasowa daga ta hanyar sun fi mayar da hankali kan tasirin tasirin parasitic da inductance.

Via's Parasitic capacitance da Inductance

A cikin ta kanta, akwai parasitic stray capacitance. Idan diamita na solder juriya zone a kan dage farawa Layer ne D2, diamita na solder kushin ne D1, da kauri daga cikin PCB jirgin ne T, da dielectric akai substrate ne ε, da parasitic capacitance na ta rami. kusan:

C=1.41εTD1/(D2-D1)

Babban tasirin tasirin parasitic akan kewaye shine tsawaita lokacin tashin siginar da rage saurin kewayawa.

Alal misali, ga PCB da kauri na 50Mil, idan diamita na via kushin ne 20Mil (diamita na hakowa rami ne 10Mils) da diamita na solder juriya zone ne 40Mil, sa'an nan za mu iya kusantar da parasitic capacitance. ta hanyar dabarar da ke sama:

C=1.41x4.4x0.050x0.020/(0.040-0.020)=0.31pF

Adadin canjin lokacin tashi da wannan ɓangaren capacitance ya haifar yana da ƙima:

T10-90=2.2C(Z0/2)=2.2x0.31x(50/2)=17.05ps

Ana iya gani daga waɗannan dabi'u cewa ko da yake amfani da jinkirin tashiwar da ke haifar da ƙarfin parasitic na guda ɗaya ba a bayyane yake ba, idan an yi amfani da via sau da yawa a cikin layi don canzawa tsakanin yadudduka, za a yi amfani da ramuka da yawa. kuma ya kamata a yi la'akari da zane a hankali. A cikin ainihin ƙira, ana iya rage ƙarfin ƙarfin parasitic ta hanyar ƙara nisa tsakanin rami da yankin jan ƙarfe (Anti-pad) ko rage diamita na kushin.

A cikin ƙira na da'irori masu sauri na dijital, cutarwar da ke haifar da inductance na parasitic sau da yawa ya fi tasirin ƙarfin parasitic. Inductance ta parasitic jerin inductance za ta raunana gudunmawar da kewaye capacitor da raunana tace tasiri na dukan ikon tsarin.

Za mu iya amfani da wannan dabarar ƙwaƙƙwaran don kawai ƙididdige inductance parasitic na kimanin ramuka:

L=5.08h[ln(4h/d)+1]

Inda L ke nufin inductance na via, h shine tsawon via, kuma d shine diamita na rami na tsakiya. Ana iya gani daga ma'anar cewa diamita na via yana da ɗan tasiri a kan inductance, yayin da tsawon ta hanyar yana da tasiri mafi girma akan inductance. Har yanzu ta yin amfani da misalin da ke sama, ana iya ƙididdige inductance daga cikin rami kamar:

L=5.08x0.050[ln(4x0.050/0.010)+1]=1.015nH

Idan lokacin tashin siginar shine 1ns, to daidai girman girmansa shine:

XL=πL/T10-90=3.19Ω

Irin wannan impedance ba za a iya watsi da a gaban high-mita halin yanzu ta, musamman, lura cewa kewaye capacitor bukatar wuce ta biyu ramukan a lokacin da haɗa da ikon Layer da samuwar, sabõda haka, parasitic inductance na rami za a ninka.

Yadda za a yi amfani da via?

Ta hanyar binciken da ke sama na halayen parasitic na rami, za mu iya ganin cewa a cikin ƙirar PCB mai sauri, ramukan da ke da sauƙi sau da yawa suna kawo mummunar tasiri ga ƙirar kewaye. Don rage mummunan tasirin da sakamakon parasitic na rami ya haifar, zane zai iya zama kamar yadda zai yiwu:

Daga bangarorin biyu na farashi da ingancin sigina, zaɓi madaidaicin girman ta hanyar girman. Idan ya cancanta, zaka iya yin la'akari da yin amfani da nau'o'i daban-daban na vias, irin su don samar da wutar lantarki ko ramukan waya na ƙasa, za ka iya yin la'akari da yin amfani da girman girma don rage rashin ƙarfi, kuma don siginar sigina, zaka iya amfani da ƙarami ta hanyar. Tabbas, yayin da girman ta hanyar raguwa, farashin da ya dace kuma zai karu

Za'a iya ƙaddamar da dabaru guda biyu da aka tattauna a sama cewa yin amfani da allon PCB mai laushi yana da amfani don rage sigogin parasitic guda biyu na via.

Bai kamata a canza siginar siginar da ke kan allon PCB ba gwargwadon yuwuwa, wato, yi ƙoƙarin kada a yi amfani da ta hanyar da ba dole ba.

Dole ne a huda Vias a cikin fil ɗin samar da wutar lantarki da ƙasa. Gajeren gubar tsakanin fil da ta hanyar, zai fi kyau. Ana iya huda ramuka da yawa a layi daya don rage kwatankwacin inductance.

Sanya wasu ramuka na ƙasa kusa da ramukan canjin siginar don samar da madauki mafi kusa don siginar. Hakanan zaka iya sanya wasu ramukan ƙasa da yawa akan allon PCB.

Don allunan PCB masu saurin gudu tare da babban yawa, zaku iya la'akari da amfani da ƙananan ramuka.