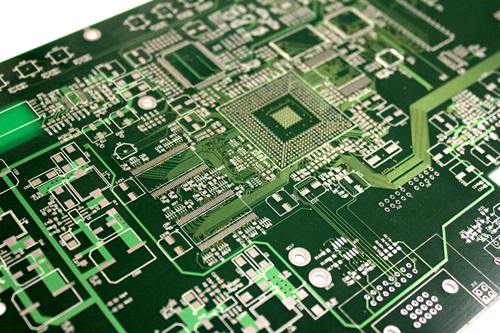

Girman samfuran lantarki yana zama mai zurfi da ƙarami, kuma kai tsaye yana tursasawa ta hanyar makafi vas hanya ce mai tsari. Don yin kyakkyawan aikin ramuka, da farko, layin ƙasa na ƙasan rami ya kamata a yi sosai. Akwai hanyoyin masana'antu da yawa, da kuma wuraren cika rami na lantarki shine ɗayan wakilai.

1. Amfanin da ba da karancin riƙi da rami cika:

(1) yana da dacewa ga ƙirar ramuka da ramuka a farantin;

(2) Inganta aikin lantarki da taimakawa babban-mitar.

(3) yana taimakawa diskipate zafi;

(4) rami mai toshe da kuma masu haɗin lantarki an kammala su a mataki ɗaya;

(5) Cike da ramin tagulla yana cike da tagulla, wanda ke da aminci mafi girma da kuma aiki da aiki fiye da batun batun yin mawadaci

2. Shafi na zahiri

Sigogi na jiki waɗanda ke buƙatar yin nazari sun haɗa da: Nau'in maimaitawa, nisa tsakanin kofin jiki, yawan zafin jiki, zazzabi, acikin tashin hankali, da sauransu.

(1) Nau'in akwatin. Idan ya zo ga nau'in akwatiniya, ba komai bane illa narkewa mai narkewa da kuma shigar da iska mai banƙu. Hanyoyin da aka narkewa yawanci phosphorus ne-mai dauke da bugun jini, wanda ke yiwuwa ga kundin akwatin, ka sanya matsalar aurarar da maganin. InsoluBle oteode, rashin buƙatar don gyara uwan, babu wani laka a ciki, dace da bugun jini ko DC baƙo; Amma yawan ƙari da ƙari ne in mun gwada da girma.

(2) Katuri da kuma karu. Designirƙirar rarrabuwar tsakani tsakanin Katolika da otar a cikin wuraren ɗaukar rami mai mahimmanci yana da matukar muhimmanci, kuma ƙirar kayan aiki daban-daban ma sun bambanta. Duk yadda aka tsara, bai kamata ya karya dokar farko ta Farko ta farko ba.

(3) dama. Akwai nau'ikan tuki iri iri, gami da injiniya na injiniya, girgizawa, venseatic vibration, iska mai tsauri, jirgin ruwa ya gudana da sauransu.

Don ɗaukar rami mai ɗaukar nauyi, an fi son ƙara tsarin jet ɗin dangane da tsarin silinda na cikin gargajiya. Lambar, karawa da kwana na jiragen sama a kan bututun jet dukansu ne a cikin ƙirar silinda ta silinda, kuma dole ne a gudanar da manyan gwaje-gwaje.

(4) Rashin lafiya da zazzabi. Yawan yanayin zafi na yanzu da ƙarancin zafin jiki na iya rage adadin sakawa a farfajiya a farfajiya, yayin samar da isasshen cu2 da haske a cikin pores. A karkashin wannan yanayin, ramin cikawa yana inganta aiki, amma an rage karfin da aka rage.

(5) Mai tsara. Maigiba mai mahimmanci shine mahimmancin haɗi a cikin tsari na mara amfani. A halin yanzu, binciken a kan rami cika ta hanyar lantarki da yawa ana iyakance ga cikakkiyar zartarwa. Idan an yi la'akari da tsinkayen rami mai cike da rami, yankin kabarin zai zama ƙanana. A wannan lokacin, ana iya sanya buƙatu mai yawa akan fitowar daidaito na rectifier.The abubuwan fitarwa na reptifier ya kamata a zaɓi gwargwadon layin samfurin da girman ramin. The bakin ciki layin da kuma karami ramuka, mafi girman bukatun bukatun Reprifier ya kamata. Gabaɗaya, yana da kyau a zaɓi mai jan ragi tare da daidaitaccen fitarwa a cikin 5%.

(6) Muguwar. A halin yanzu, daga hangen nesa na RagesPlatire, akwai nau'ikan da ba za a iya amfani da ramuka guda biyu da cika ramuka ba: bugun lantarki da kuma kai tsaye mara amfani. Ana amfani da na gargajiya mai ƙarfi don shirya na yau da kullun da kuma gilashin rami, wanda yake mai sauƙin aiki, amma idan farantin yana da kauri, babu wani abin da za a iya yi. Ana amfani da PPR rebrefier don bugun jini da kuma gilashin rami, kuma akwai matakai masu yawa, amma yana da ƙarfin aiki mai ƙarfi don allon da kuka yi.