Saboda nau'ikan substrates, tsarin masana'antu na rigakafin-flex PCB ya bambanta. Babban matalauta da ke tantance aikinsa shine sananniyar fasahar waya da fasahar micropicorous. Tare da buƙatun miniacitization, aiki mai yawa da kuma babban taro na samfuran lantarki, masana'antar masana'antu mai sassauci na fasaha mai sassauƙa PCB ta zama mai hankali sosai.

M Tsarin Magunguna na PCB PCB:

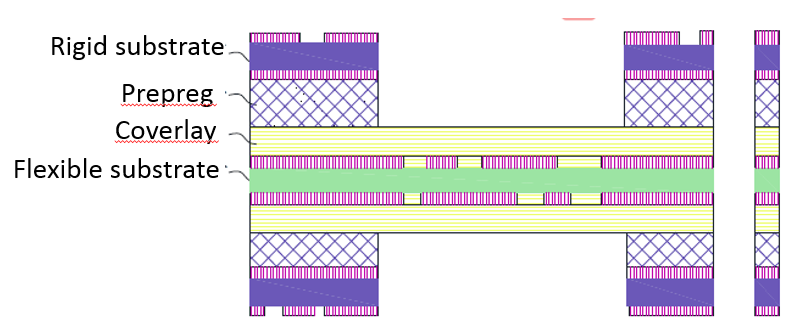

M-fllect pcb, ko rfcloch korar allo ne wanda ya hada da m PCB da m PMB, wanda zai iya samar da hanyar ta hanyar Pth.

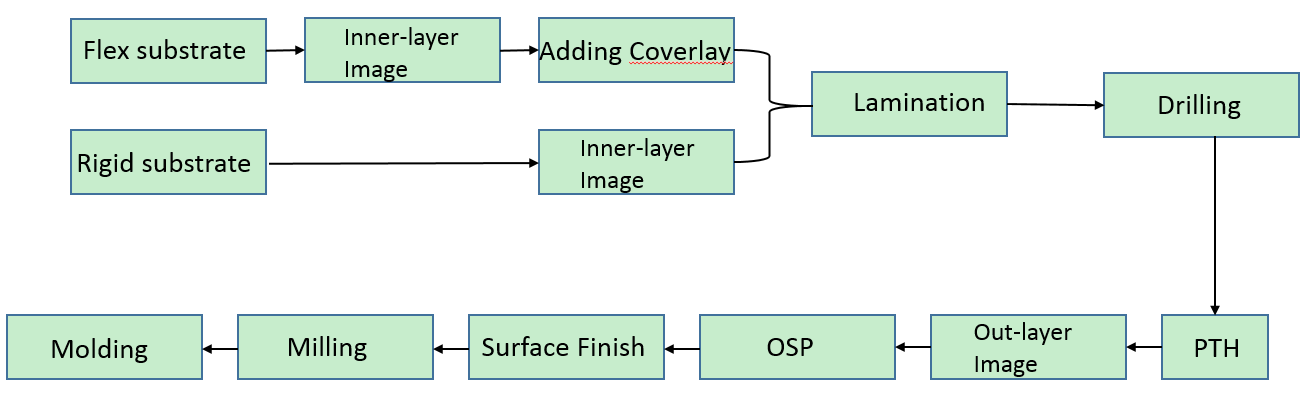

Tsarin masana'antu mai sauƙi na m-flex PCB:

Bayan ci gaba ci gaba da ci gaba, daban-daban sabon tsauraran masana'antu fasahar samar da kayayyaki na ci gaba da fito fili. Daga gare su, tsarin masana'antar masana'antu shine amfani da tsayayye fr-4 kamar yadda mayafin substrate na tsaurara da aka gyara na m pcb abubuwan da aka gyara. M amfani da abubuwan haɗin PCB ɗin suna amfani da fim ɗin PI azaman mai sassauƙa mai sassauƙa kuma rufe polyimide ko acrylic. Advesives suna amfani da ƙananan shirye-shiryen da ke gudana, kuma a ƙarshe waɗannan subbratratrater an ɗora su tare don yin rigakafin-fuck ne.

Haɓaka Trend na ƙwarewar fasahar-Flean Scleirƙira

A nan gaba, mai saurin kwaya za su ci gaba a cikin shugabanci na kwarai-mai-rai, da yawa, ta hanyar aiki da kayan masana'antu masu dacewa. Tare da haɓaka fasahar duniya da masana'antun masana'antu, fannoni masu sassauƙa da ƙwayoyin cuta masu sassauƙa suna haɓaka haɓakawa zuwa tsakani, galibi a cikin masu zuwa.

1) Bincike da haɓaka fasahar sarrafa fasaha da kuma kayan masarufi.

2) Bangare cikin fasahar kayan aikin polymer don saduwa da manyan abubuwan zazzabi.

3) Manyan na'urori da kayan sassauƙa zasu iya samar da manyan kwamfyuta da ƙarin m.

4) Kara yawan shigarwa da fadada kayan haɗin da aka saka.

5) da'irar PCB ta PCB.

6) An haɗa shi da katangar lantarki.

A taƙaice, fasahar masana'antu na tsayayye-sassauƙa da'irar allon allon (kwaya) ya ci gaba zuwa ci gaba, amma an ci gaba da fuskantar matsalolin fasaha. Koyaya, tare da ci gaba da haɓaka fasahar samfuri na lantarki, masana'antu na m PBB