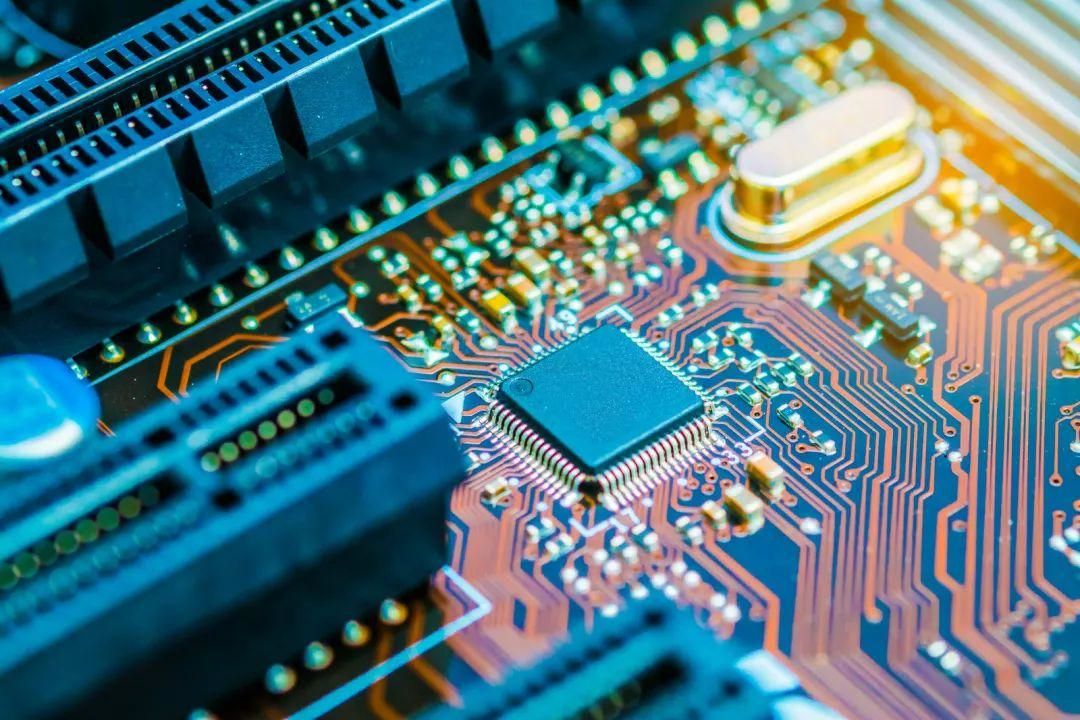

PCB kewaye hukumar a samar da tsari, sau da yawa gamu da wasu tsari lahani, kamar PCB kewaye hukumar jan karfe waya kashe bad (kuma sau da yawa aka ce jefa jan karfe), shafi samfurin quality. Dalilan gama gari na PCB da'irar da'ira amai jan karfe sune kamar haka:

PCB kewaye hukumar tafiyar matakai

1, Jaka tsare etching ya wuce kima, electrolytic tagulla tsare amfani a kasuwa ne kullum guda-gefe galvanized (wanda aka fi sani da launin toka tsare) da kuma guda-gefe plated jan karfe (wanda aka fi sani da ja tsare), na kowa jan karfe ne kullum fiye da 70um galvanized. Bakin tagulla, jajayen foil da 18um da ke ƙasa da ainihin foil ɗin toka ba su kasance gungu na jan karfe ba.

2. Local karo na faruwa a PCB tsari, da kuma jan karfe waya aka rabu da substrate ta waje inji karfi. Wannan lahani yana bayyana azaman matsawa mara kyau ko daidaitawa, faɗuwar waya ta tagulla za ta sami ɓarna a fili, ko kuma a hanya ɗaya ta alamar karce/tasiri. Cire mummunan ɓangaren wayar jan ƙarfe don ganin fuskar bangon tagulla, za ku iya ganin launi na yau da kullun na farfajiyar foil ɗin tagulla, ba za a sami mummunan yashwar gefen ba, ƙarfin bawon tagulla na al'ada ne.

3, PCB kewaye zane ba m, tare da kauri jan karfe zane zane na ma bakin ciki line, kuma zai haifar da wuce kima line etching da jan karfe.

Laminate tsari dalili

A karkashin yanayi na al'ada, idan dai sashin zafin jiki mai zafi na laminate sama da mintuna 30, foil na jan karfe da takardar da aka warke gabaɗaya an haɗa su gabaɗaya, don haka latsa gabaɗaya ba zai shafi ƙarfin ɗaurin jan karfe da substrate a cikin laminate ba. Duk da haka, a cikin aiwatar da laminate stacking da stacking, idan PP gurbatawa ko tagulla rufi surface lalacewa, shi kuma zai haifar da rashin isasshen bonding karfi tsakanin jan karfe da substrate bayan laminate, sakamakon matsayi (kawai ga babban farantin) ko sporadic jan karfe waya. asara, amma ƙarfin tsirwar foil ɗin tagulla kusa da layin cirewa ba zai zama mara kyau ba.

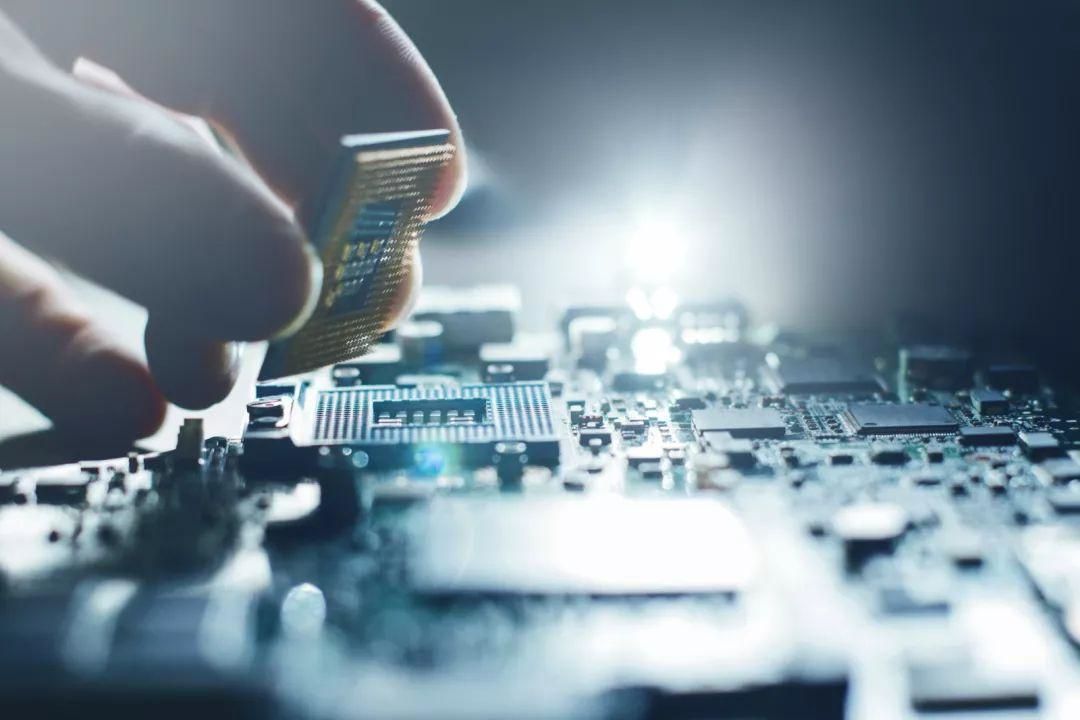

Laminate albarkatun kasa dalili

1, talakawa electrolytic jan karfe tsare ne galvanized ko jan karfe-plated kayayyakin, idan ganiya darajar da ulu tsare samar da shi ne mahaukaci, ko galvanized / jan karfe plating, shafi dendritic bad, sakamakon jan karfe tsare kanta peeling ƙarfi bai isa ba, da bad tsare. guga man da aka yi da PCB plug-in a cikin masana'antar lantarki, waya ta jan karfe za ta faɗi ta hanyar tasirin waje. Irin wannan mummunan tsiri jan ƙarfe waya tagulla surface na jan karfe (wato, lamba surface tare da substrate) bayan bayyananne gefen yashwa, amma dukan surface na jan karfe bawon ƙarfi zai zama matalauta.

2. Poor adaptability na jan karfe tsare da guduro: wasu laminates da musamman Properties ana amfani da yanzu, kamar HTg takardar, saboda daban-daban guduro tsarin, da curing wakili amfani ne kullum PN guduro, guduro kwayoyin tsarin tsarin ne mai sauki, low crosslinking digiri a lokacin da warkewa, don amfani da foil na musamman na jan karfe da ashana. Lokacin da samar da laminate amfani da jan karfe tsare da guduro tsarin bai dace ba, sakamakon takardar karfe tsare peeling ƙarfi bai isa ba, toshe-in kuma zai bayyana mummunan jan karfe waya zubar.

Bugu da ƙari, yana iya zama cewa rashin daidaituwa na walda a cikin abokin ciniki yana haifar da asarar kushin walda (musamman guda ɗaya da biyu bangarori, allon multilayer suna da babban yanki na bene, saurin zafi mai zafi, zafin walda yana da girma, ba haka ba ne mai sauƙi). a fado):

●Yin walda tabo akai-akai zai warware kushin;

●High zafin jiki na soldering baƙin ƙarfe ne mai sauki weld kashe kushin;

●Yawan matsi da kan mai siyar da ƙarfe ke yi akan kushin da tsayin lokacin walda zai iya kashe kushin.