1. PCB ta hanyar rami

Akwai hanyoyi da yawa don gina Layer na plating wanda ya dace da buƙatun akan bangon rami na substrate. Wannan ana kiransa kunna bangon rami a aikace-aikacen masana'antu. Masana'antun hukumar ta PCB suna amfani da tankunan ajiya masu yawa a cikin tsarin samarwa. Kowane tankin ajiya Tankin yana da nasa kulawa da bukatun kulawa. Ta hanyar-rami electroplating ne m zama dole masana'antu tsari na hakowa tsari. Lokacin da ɗigon rawar sojan ya faɗo ta cikin foil ɗin jan ƙarfe da abin da ke ƙasa, zafin da aka haifar yana narkar da resin roba mai rufewa wanda ya zama tushen mafi yawan abubuwan da ake amfani da su, narkakken guduro da sauran gutsuttsuran hakowa Ana ajiye shi a kusa da ramin kuma a lulluɓe shi akan sabon ramin da aka fallasa. bango a cikin foil na jan karfe, wanda a zahiri yana cutarwa ga shimfidar wuri mai zuwa.

Narkakkar guduro zai kuma bar wani Layer na zafi axis a kan ramin bango na substrate, wanda ya nuna matalauta mannewa ga mafi yawan activators, wanda na bukatar ci gaban ajin na dabaru kama da tabo cire da etchback sunadarai. Hanya ɗaya da ta fi dacewa da samfurin allunan da'irar da aka buga ita ce yin amfani da tawada mai ƙarancin ɗanɗano da aka ƙera ta musamman don samar da abin rufe fuska mai mannewa da ɗaukar nauyi sosai akan bangon ciki na kowane ta rami. Ta wannan hanyar, babu buƙatar yin amfani da hanyoyin sarrafa sinadarai da yawa, kawai mataki ɗaya na aikace-aikacen, wanda ke biye da maganin thermal, zai iya samar da ci gaba da shafi a cikin duk bangon ramin, ana iya kunna shi kai tsaye ba tare da ƙarin magani ba. Wannan tawada wani abu ne na tushen guduro wanda ke da mannewa mai ƙarfi kuma ana iya haɗa shi cikin sauƙi zuwa ga mafi yawan ganuwar ramin da aka goge da zafi, don haka yana kawar da matakin etch baya.

2. Reel linkage type zažužžukan plating

Fil da fitilun kayan aikin lantarki, kamar haɗe-haɗe, haɗaɗɗun da'irori, transistor, da allunan FPCB masu sassauƙa, duk an yi su ne don samun kyakkyawar juriya da juriya na lalata. Wannan hanyar lantarki na iya zama da hannu ko kuma ta atomatik, kuma yana da tsada sosai don zaɓar kowane fil ɗaya ɗaya don plating, don haka dole ne a yi amfani da walda mai yawa. Yawancin lokaci, iyakar biyu na bangon ƙarfe da aka yi birgima zuwa kauri da ake buƙata ana buga su, ana tsabtace su ta hanyar sinadarai ko hanyoyin injiniya, sannan a zaɓi zaɓi kamar nickel, zinariya, azurfa, rhodium, maɓalli ko tin-nickel gami, gami da jan ƙarfe-nickel, nickel. - gubar gami, da dai sauransu don ci gaba da plating. A cikin hanyar electroplating na zaɓin plating, da farko, an rufe wani Layer na fim ɗin tsayayya akan ɓangaren ƙarfe na ƙarfe na ƙarfe wanda ba ya buƙatar a sanya shi, kuma zaɓin ɓangaren bangon tagulla ne kawai aka sanya shi.

3. Sanya farantin yatsa

Ƙarfe ɗin da ba kasafai ba yana buƙatar a sanya shi a kan mahaɗin gefen allo, gefen allo yana fitowa lamba ko yatsan zinare don samar da ƙarancin juriya da juriya mafi girma. Ana kiran wannan dabarar sahun yatsa ko plating part ɗin. Zinariya sau da yawa ana lullube shi akan lambobi masu fitowa na mai haɗin gefen tare da sanya nickel a saman Layer na ciki. Yatsan zinari ko ɓangaren da ke fitowa na gefen allo yana amfani da fasaha ta hannu ko ta atomatik. A halin yanzu, platin zinari akan filogin lamba ko yatsa na zinare an yi shi da kaka da gubar, Maɓallin Maɓalli maimakon.

Tsarin shine kamar haka:

1. Cire abin rufe fuska don cire kwano ko murfin dalma a kan lambobi masu fitowa.

2. Kurkura da ruwan wanka.

3. Goge da abrasives.

4. Ana kunna kunnawa a cikin 10% sulfuric acid.

5. The kauri na nickel plating a kan protruding lambobin sadarwa ne 4-5μm.

6. A wanke da cire ruwan ma'adinai.

7. Maganin maganin shigar zinare.

8. Zinariya.

9. Tsaftacewa.

10. Bushewa.

4. Goge plating

Fasaha ce ta electrodeposition, kuma ba dukkan sassa ne ke nutsewa a cikin electrolyte ba yayin aikin lantarki. A cikin wannan fasaha na lantarki, yanki mai iyaka ne kawai ake sanya wutar lantarki, kuma ba shi da wani tasiri a kan sauran. Yawancin lokaci, karafa da ba kasafai ake yi ba akan zaɓaɓɓun sassa na allon da'irar da aka buga, kamar wurare kamar masu haɗa gefen allo. Ana amfani da goge goge sau da yawa a cikin gyaran allunan da'irar sharar gida a cikin shagunan hada kayan lantarki. Kunna wani anode na musamman (anode wanda ba shi da sinadarai, kamar graphite) a cikin wani abu mai narkewa (swab auduga) kuma amfani da shi don kawo maganin plating zuwa wurin da ake buƙatar plating.

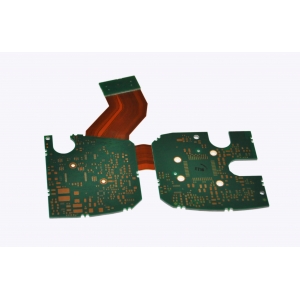

Fastline Circuits Co., Limited ƙwararre ce: PCB kewaye hukumar masana'anta, samar muku da: PCB proofing, tsari tsarin jirgin, 1-34 Layer PCB jirgin, high TG jirgin, impedance jirgin, HDI jirgin, Rogers hukumar, Manufacture da kuma samar da PCB kewaye allon na daban-daban. matakai da kayan aiki kamar allunan microwave, allunan mitar rediyo, allon radar, allo mai kauri na jan karfe, da sauransu.