about us

about

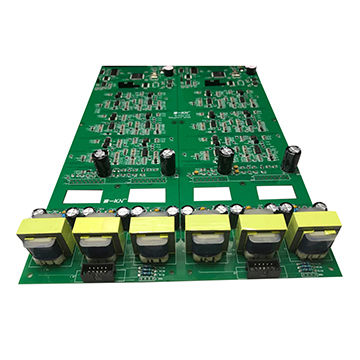

Fastline Circuits Co.,Limited has the most diversified printed circuit board technologies available, including Multi-layer PCB, Aluminum based PCB, Ceramic PCB, HDI PCB, Flexible PCB, Rigid-flex PCB, Heavy Copper PCB, Rogers PCB and pcb assembly,etc. We offer a one-stop solution for customers. We believe that the quality is the soul of an enterprise and provides time-critical, technologically advanced engineering an manufacturing services for the electronics industry. Sound quality gains a good reputation for Fastline. Loyal customers have cooperated with us again and again and new customers come to Fastline to establish cooperation relationship when they hear of a great reputation. We look forward to offering high-quality service to you!

our advantages

-

OWN FACTORY

pcb layout services,911EDA is an Industry Leader in PCB Layout and PCB Design, supporting customers for over 17 years. -

EXCELLENT TEAM

Mature technical team, workers team, you only need to let us know your idea -

GOOD QUALITY

To deliver true value and convenience to our PCB fabrication customers, we offer advanced turnkey PCB assembly service. -

AFTER SALE SERVICE

Advanced management concepts and service awareness

main products

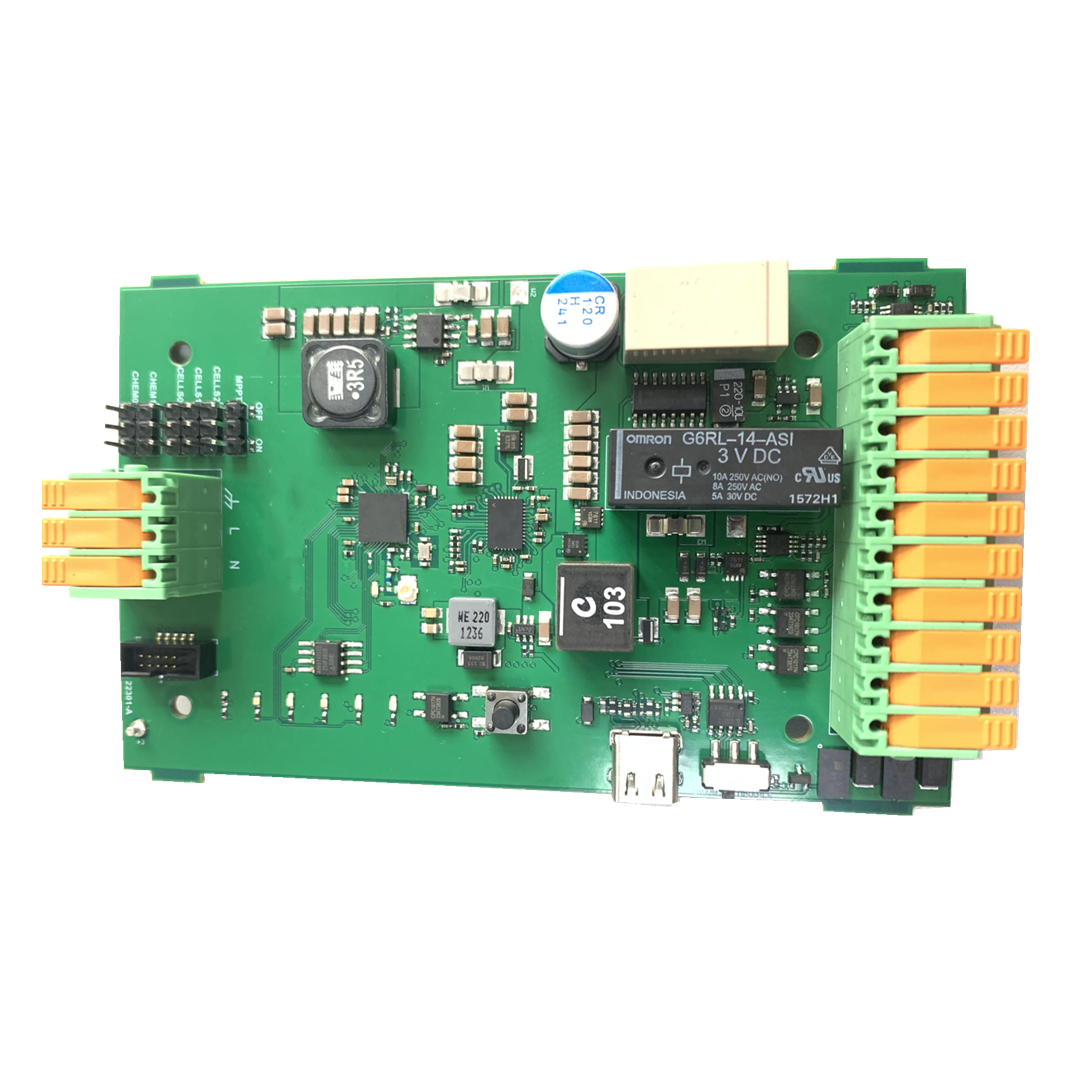

- PCB Assembly

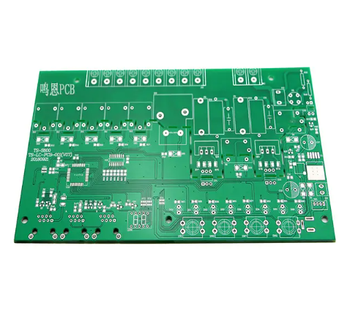

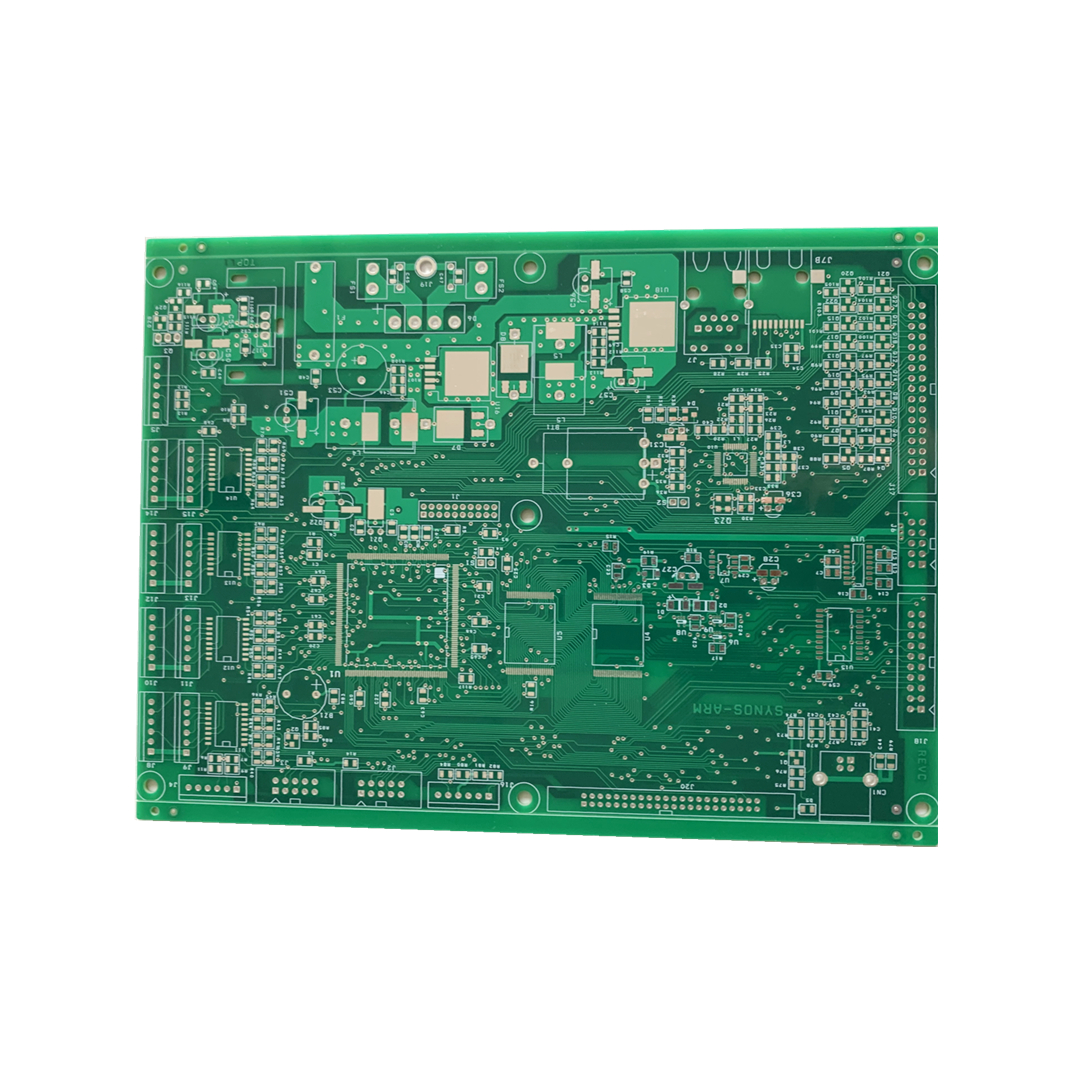

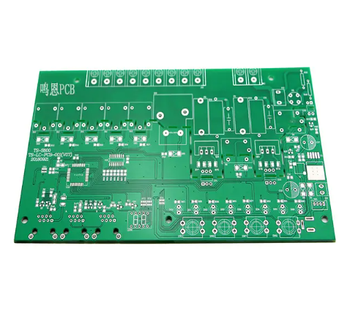

- Fr4 PCB

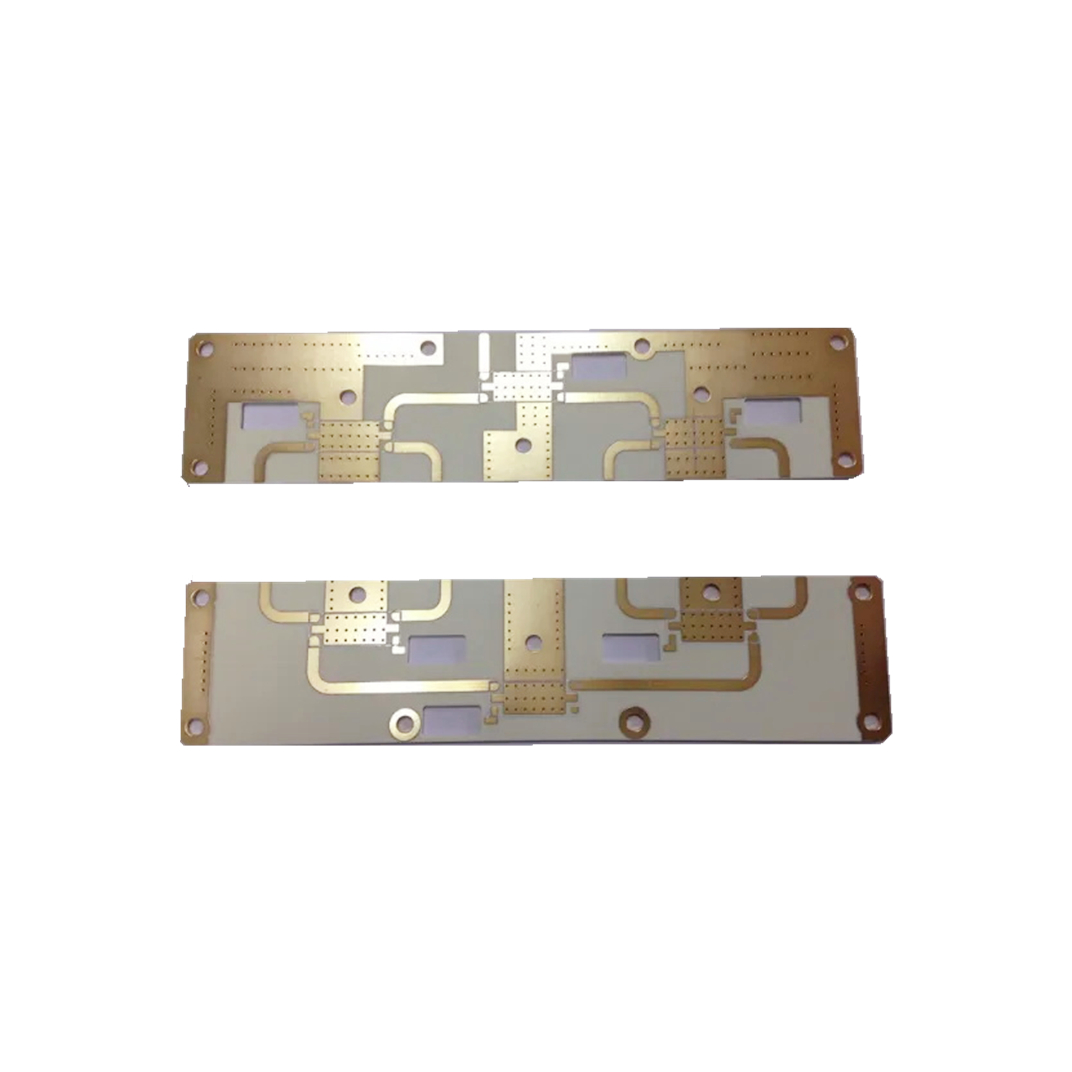

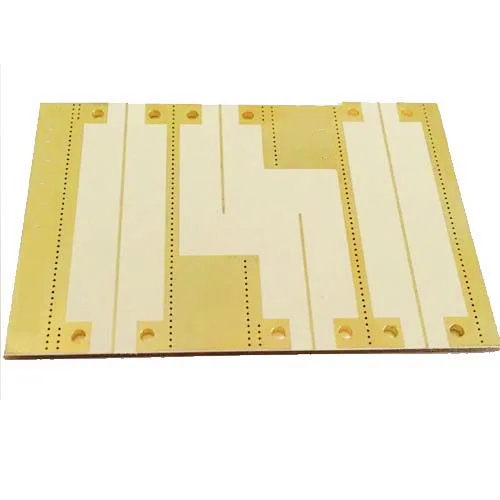

- Rogers PCB

- Flexible PCB

- Rigid-Flexible PCB

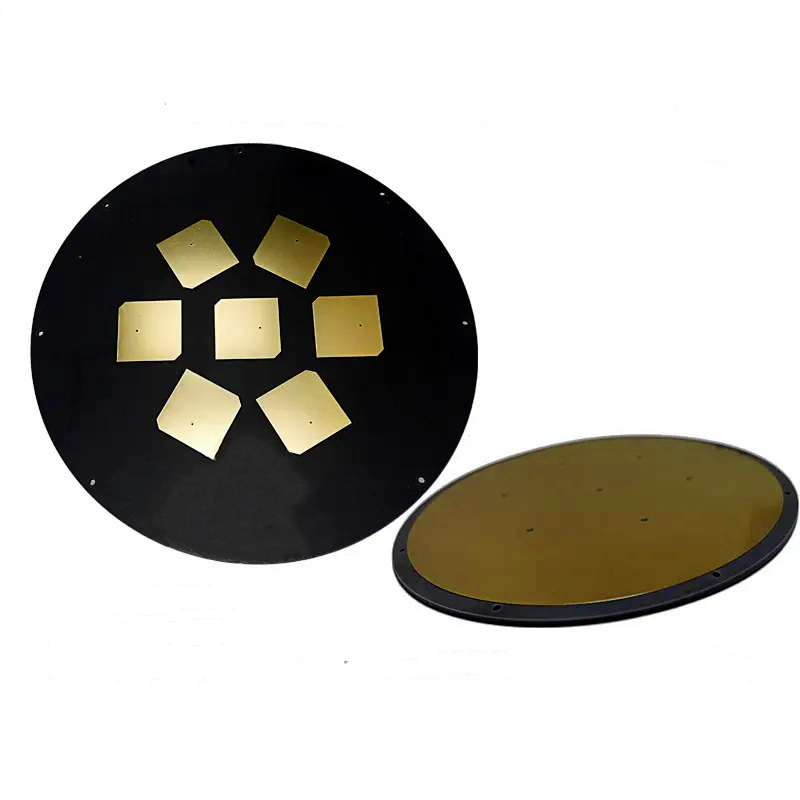

- Matel Core PCB

-

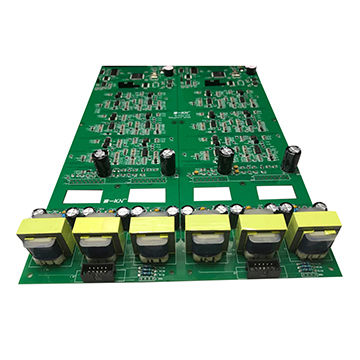

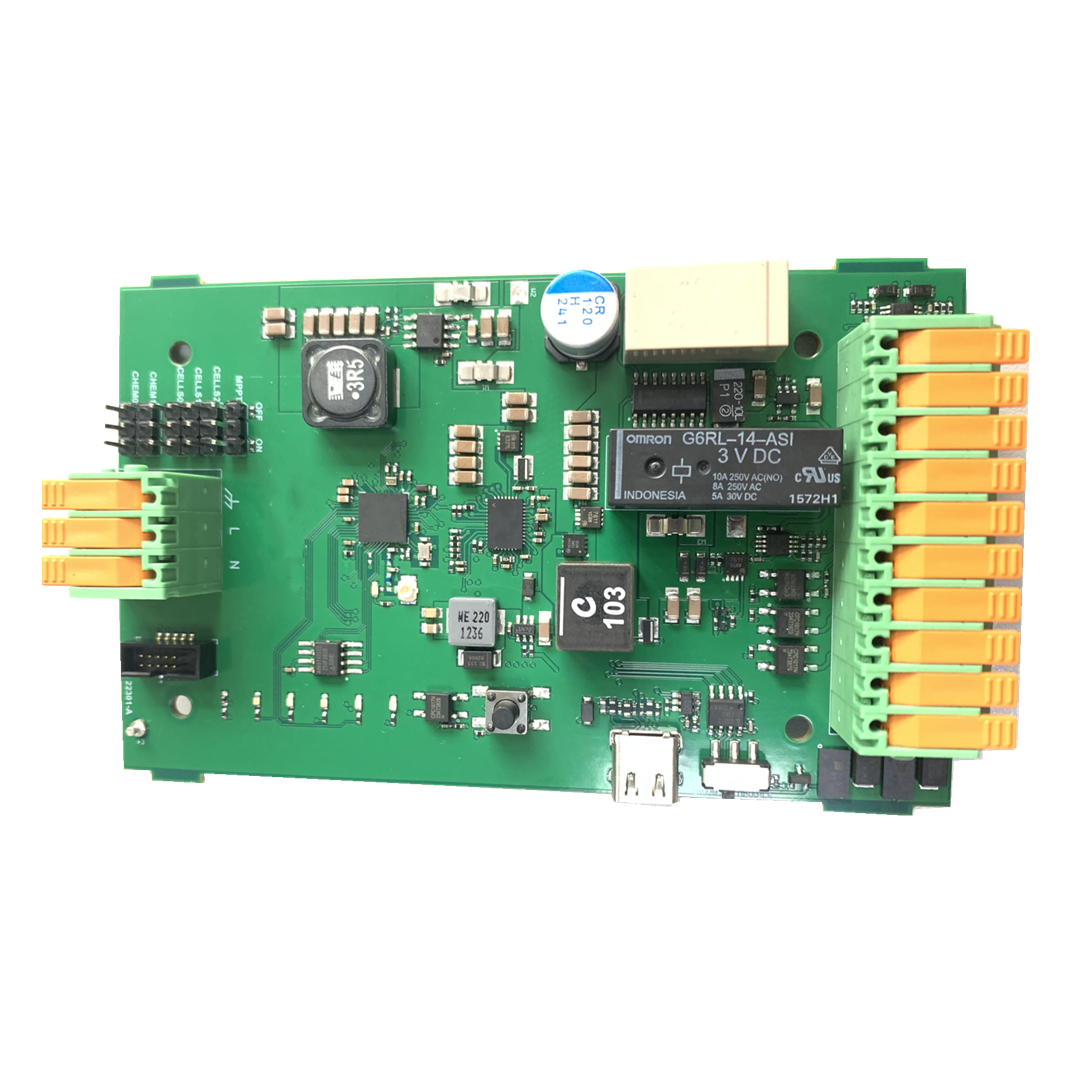

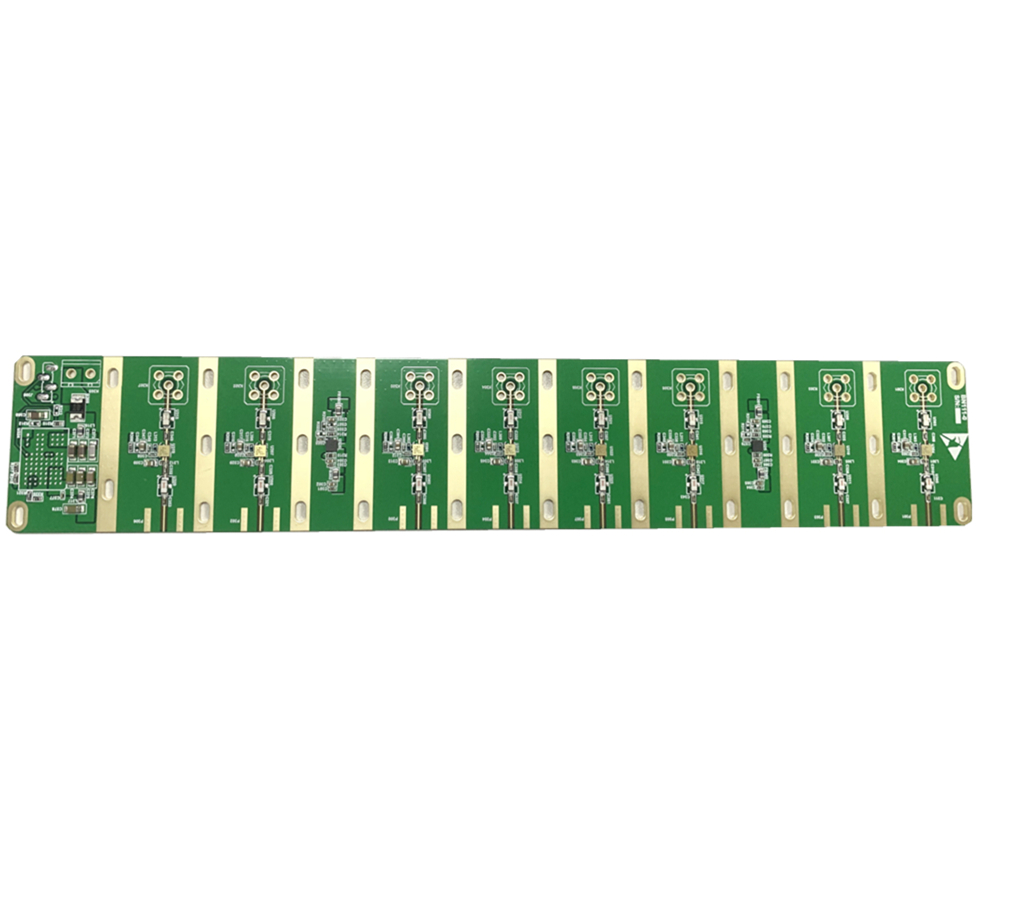

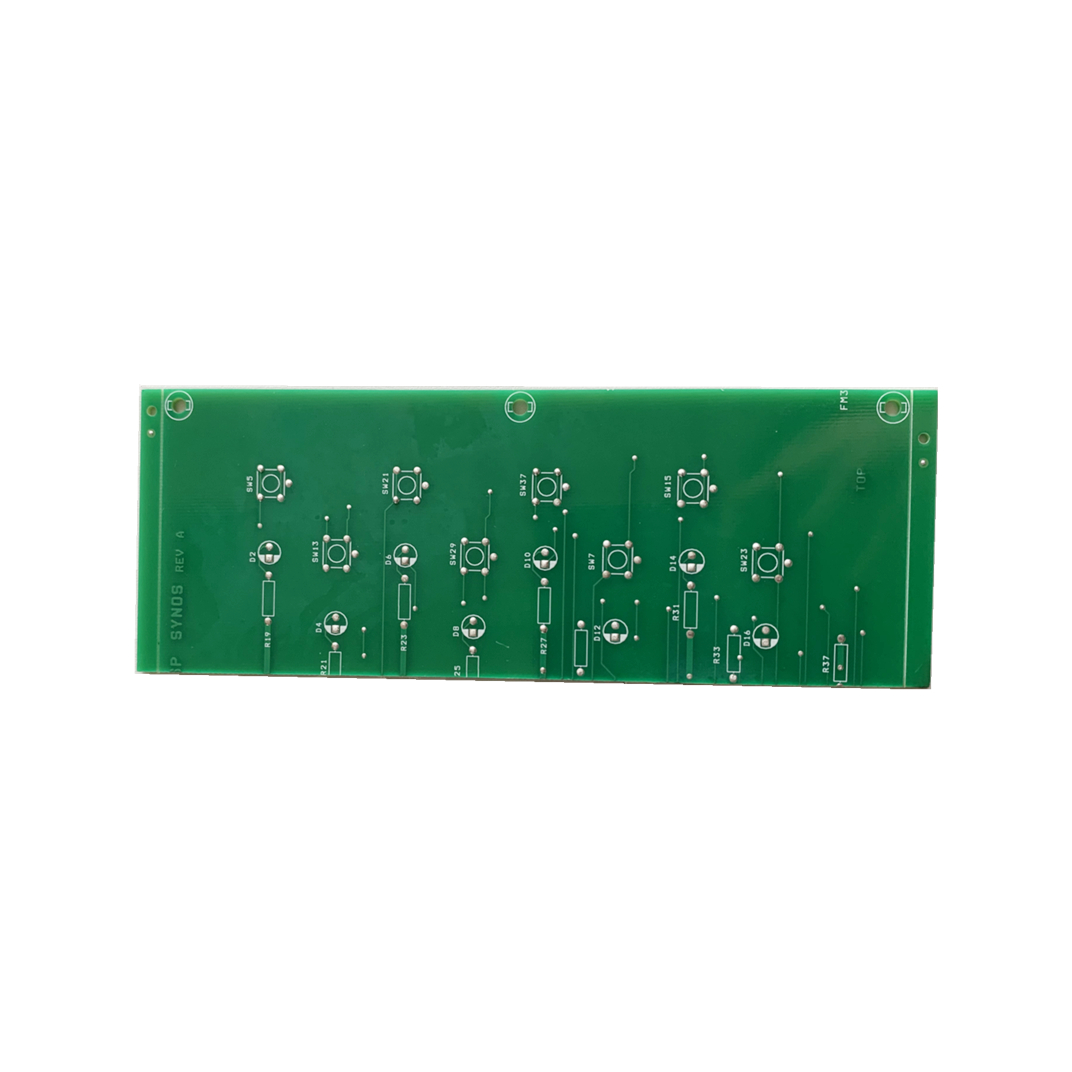

Fr4/94v0 Double Sided PCB Fr4 PCB Assembly

-

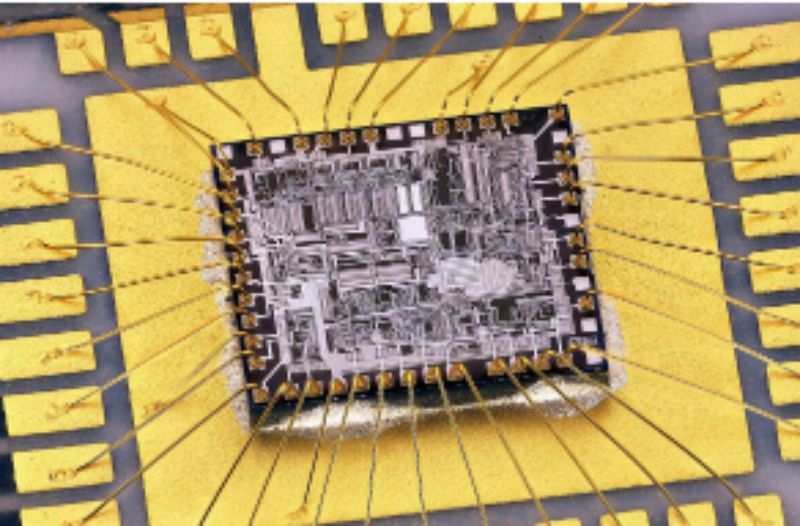

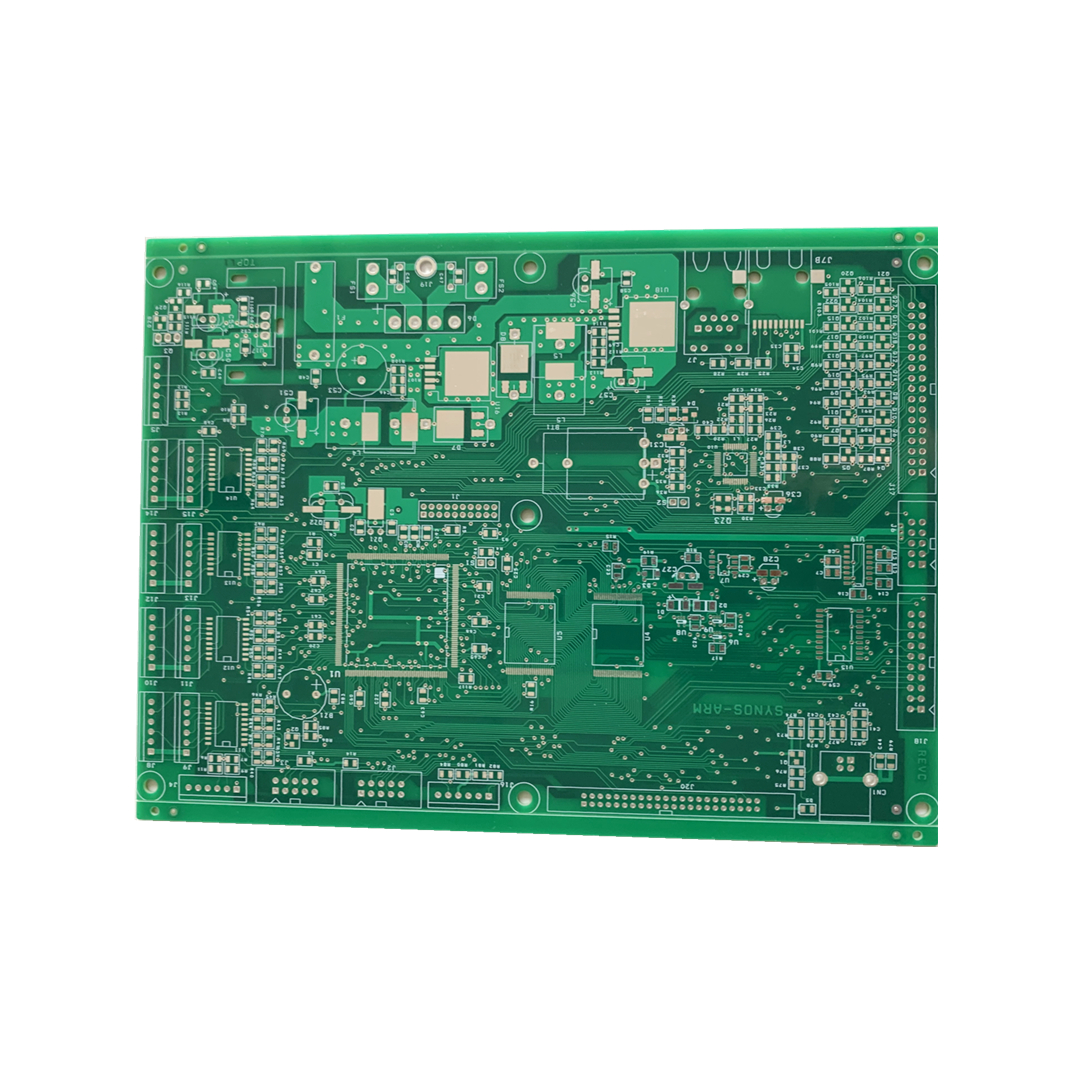

HDI Electronics Products Circuit Board Assembly PCBA

-

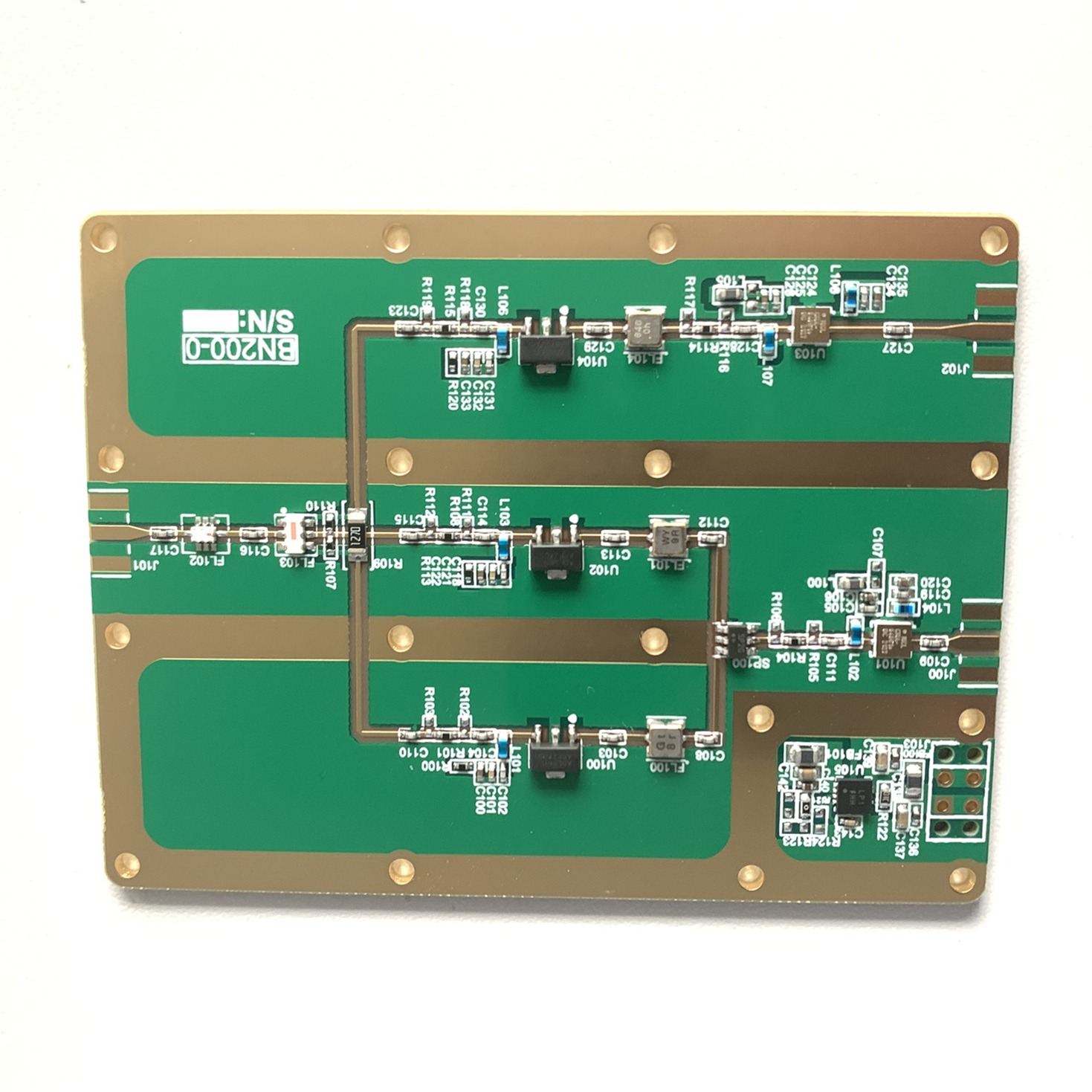

Main Roger+FR4 Circuit board PCB Assembly

-

Rogers Custom Electronics Circuit Board Assembly

-

Integrated Circuit Board PCB Fr4 Double Layer Bare substrate pcb

-

Fr4 High Tg 1.6mm 12layer Imm Gold Motherboard Circuit PCB

-

Electronics Metal Detector pcb board

-

FR4 HDI 4 Layers Main Circuit board

-

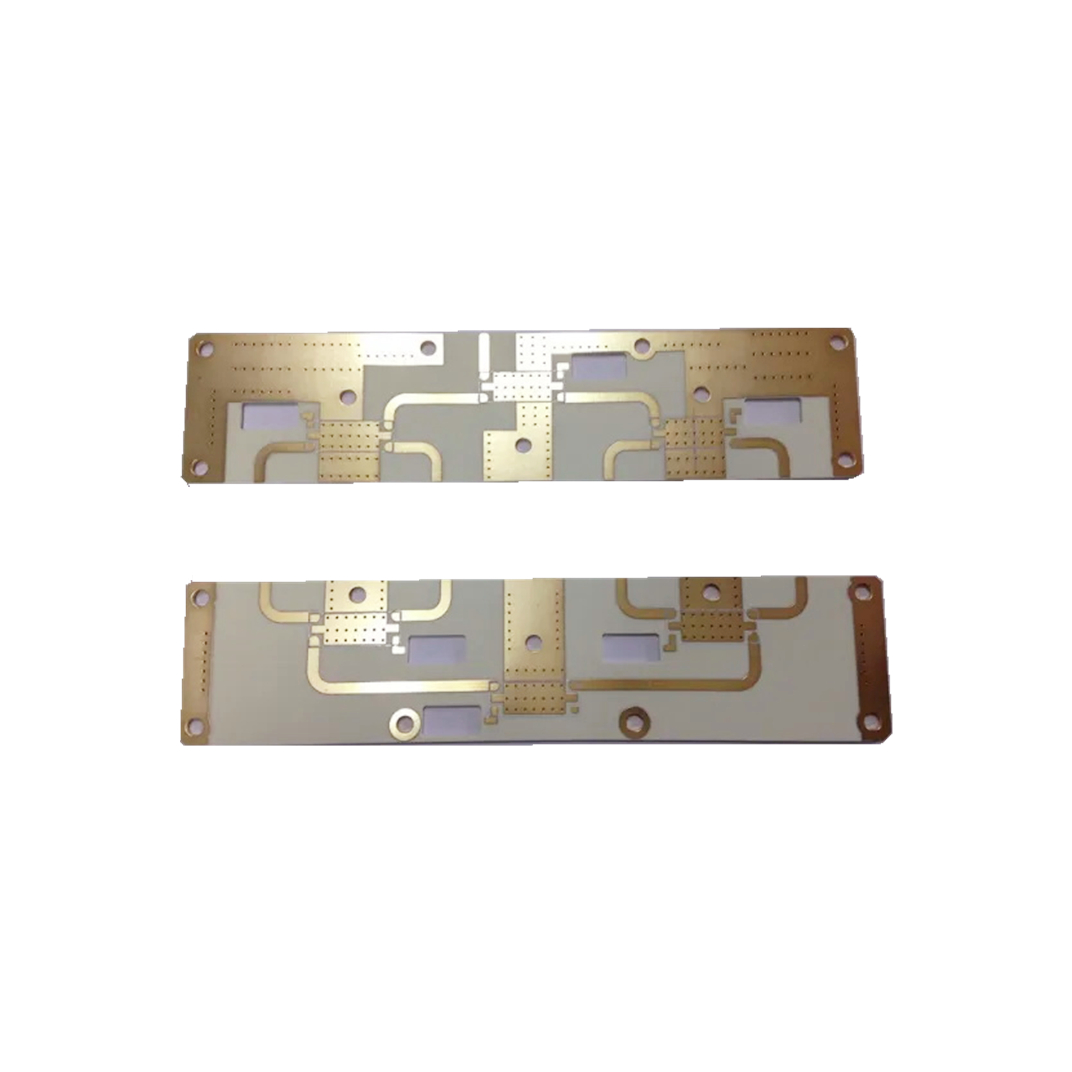

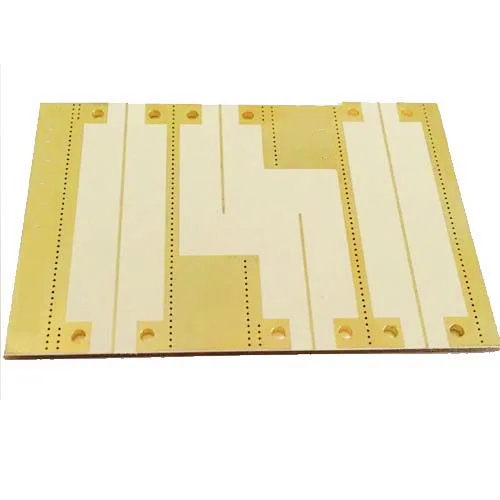

Rogers Raw material Electrionics Circuit Board PCB

-

Rogers 5880 Electrionics Parts Circuit Board PCB

-

Auto parts Rogers board Pcb Circuits Board

-

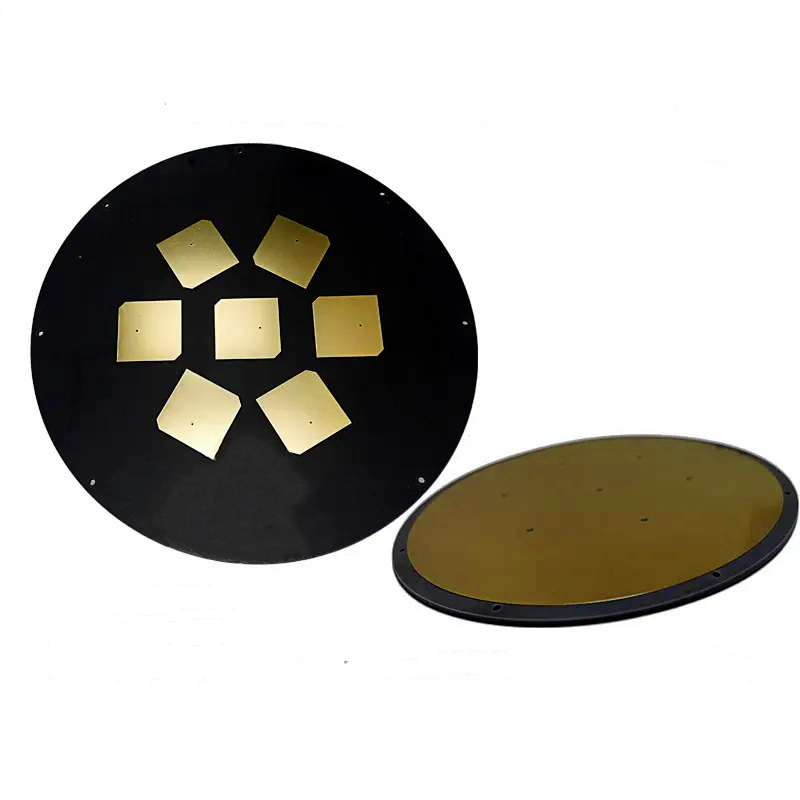

Black Soldermask Motherboard PCB

-

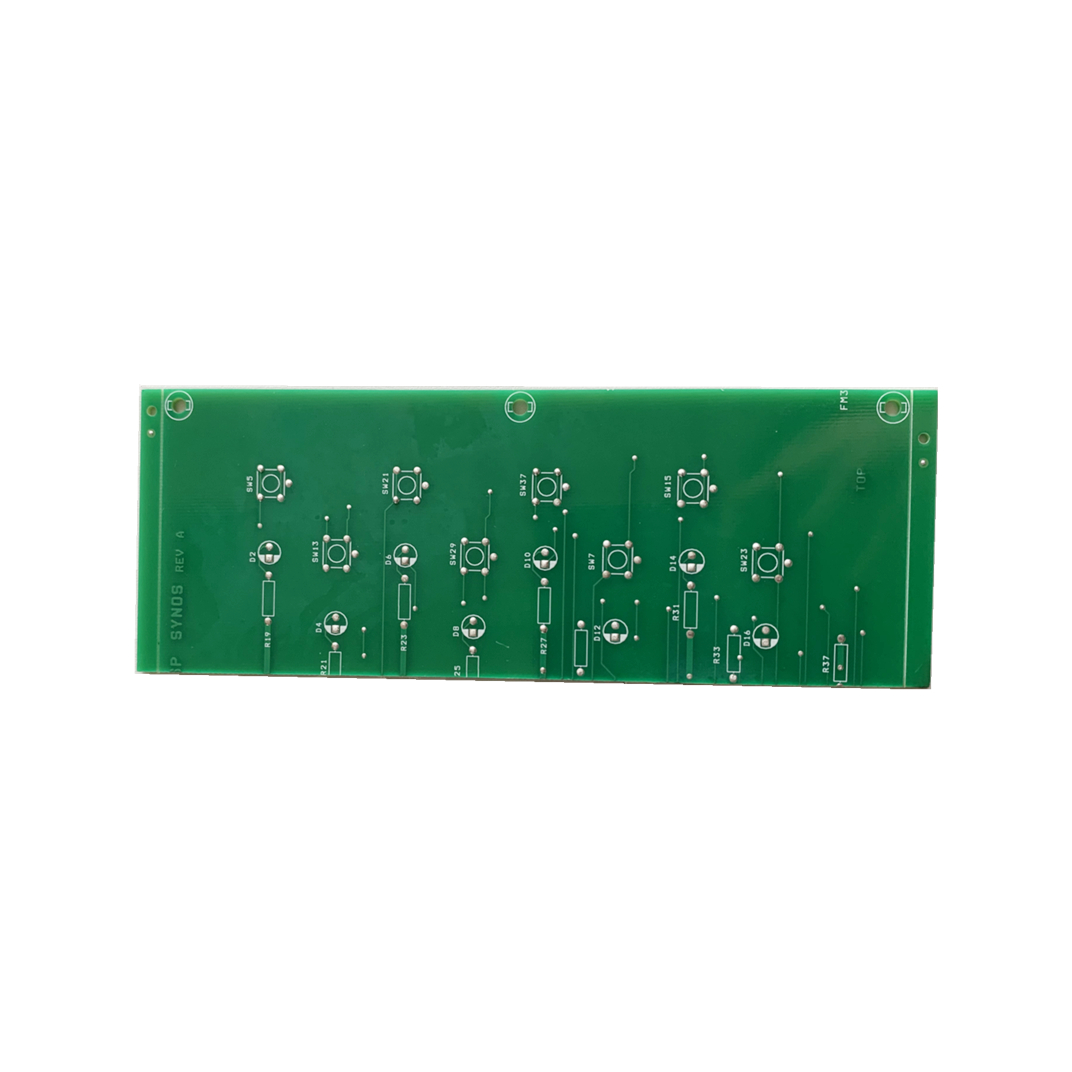

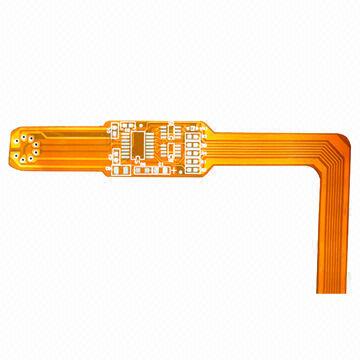

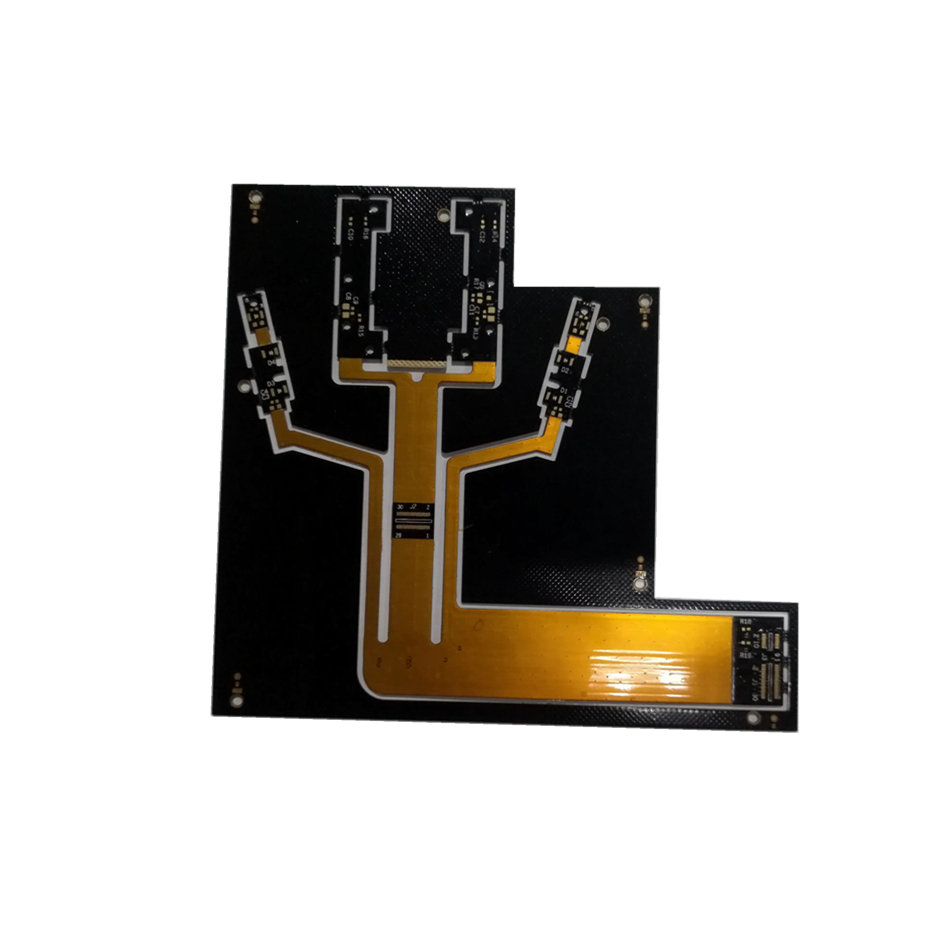

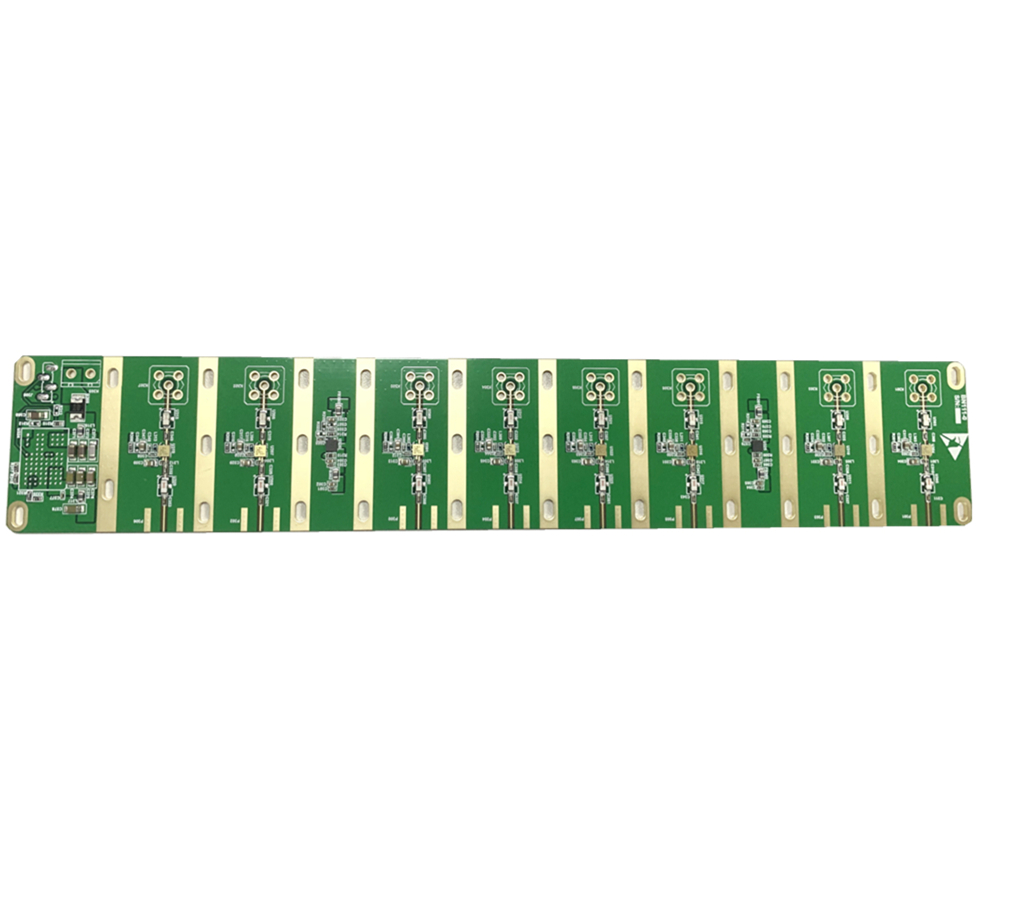

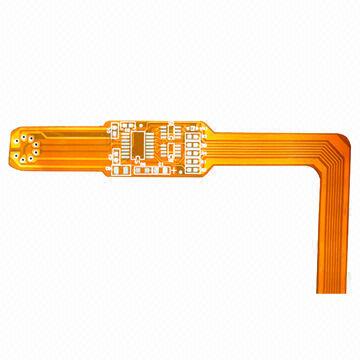

Controlling FPC Circuit Board

-

FPC Mainboard Flexible PCB

-

8 layers Multilayer Flexible PCB

-

Thick Copper Soldering Flexible PCB

-

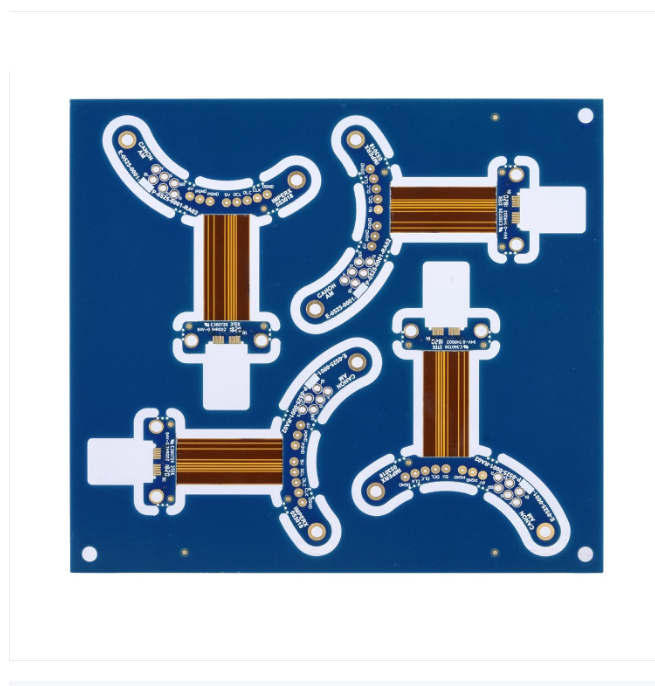

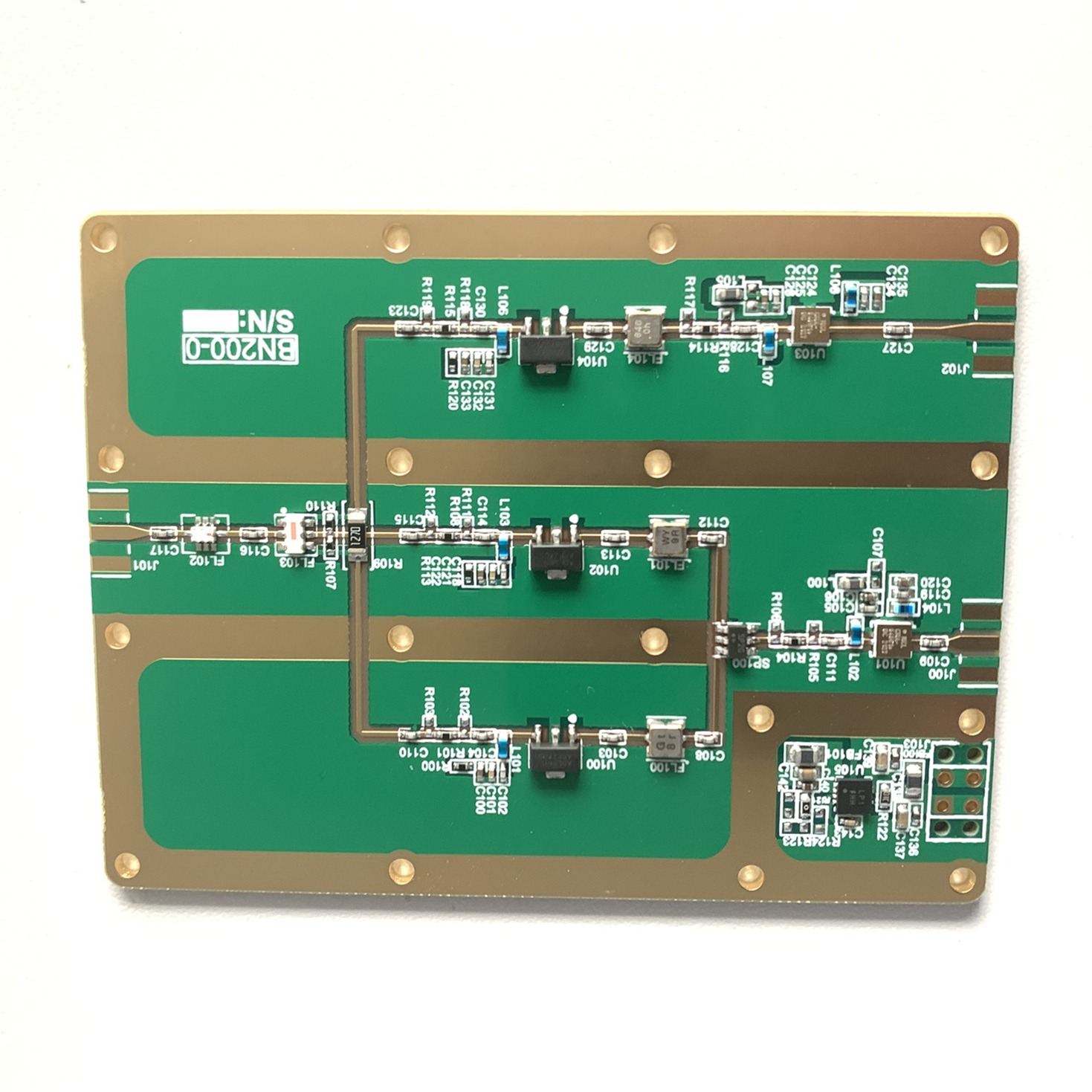

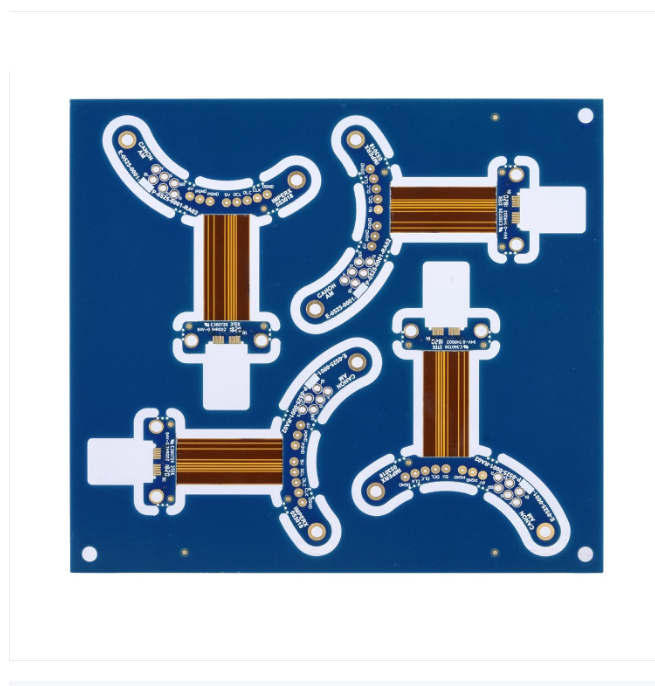

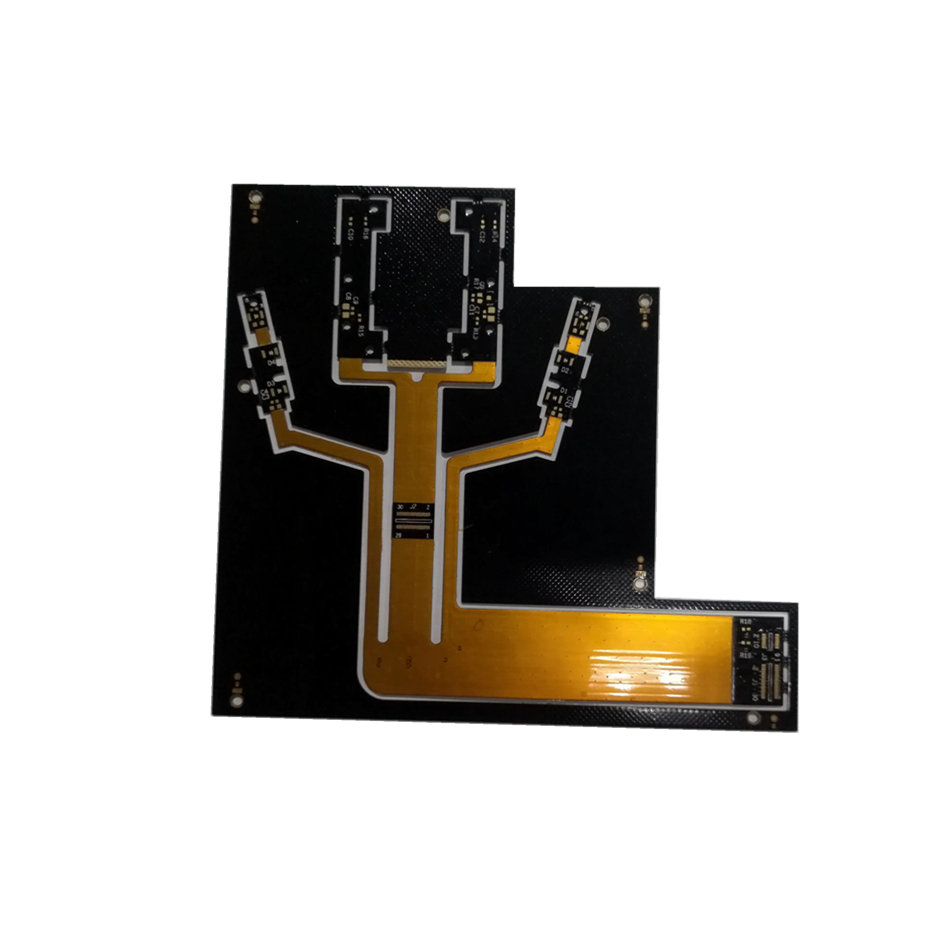

Blue Rigid-flex Mainboard Circuit Board

-

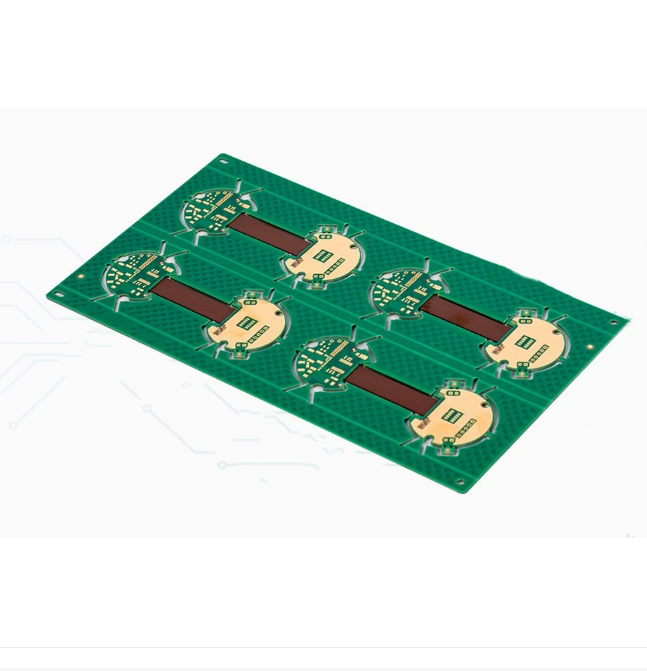

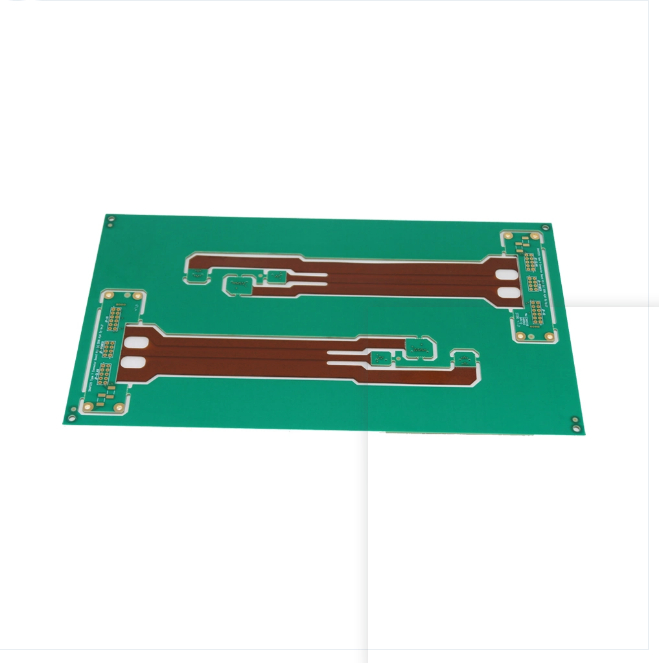

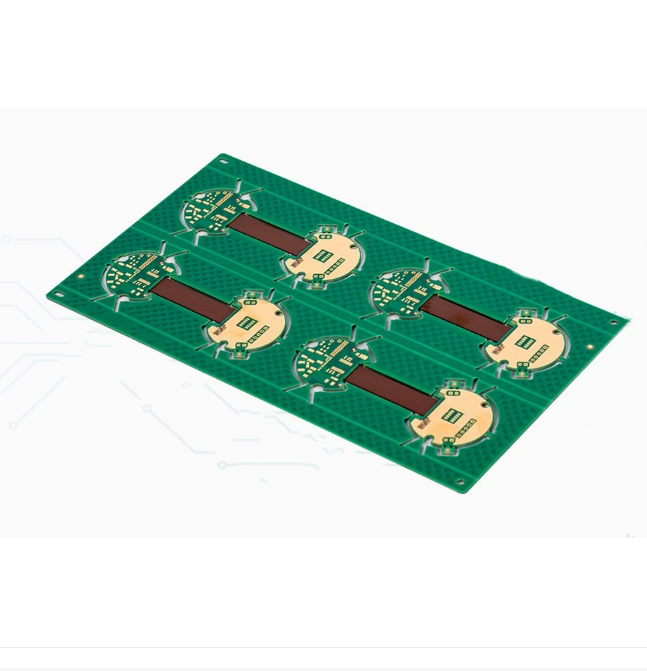

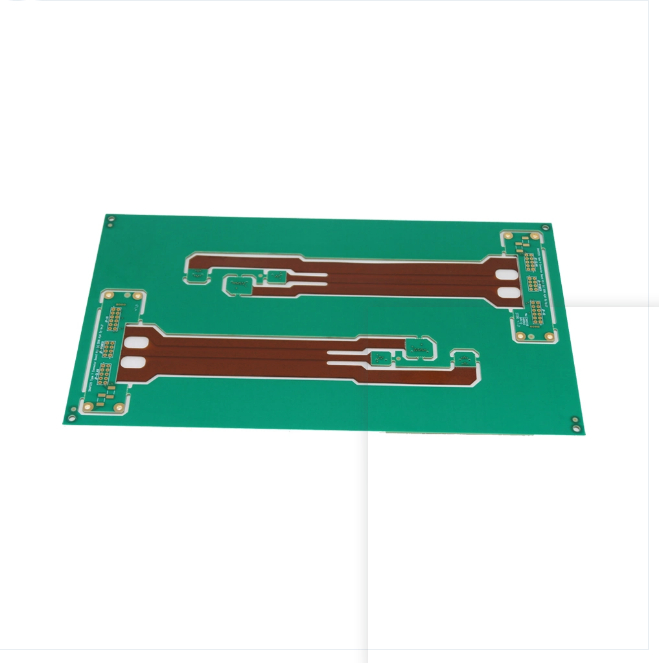

Green Soldermask Rigid- Flex Circuit board PCB

-

4 layers rigid-flex PCB board

-

HDI Mainboard Rigid-Flex Circuit board PCB

-

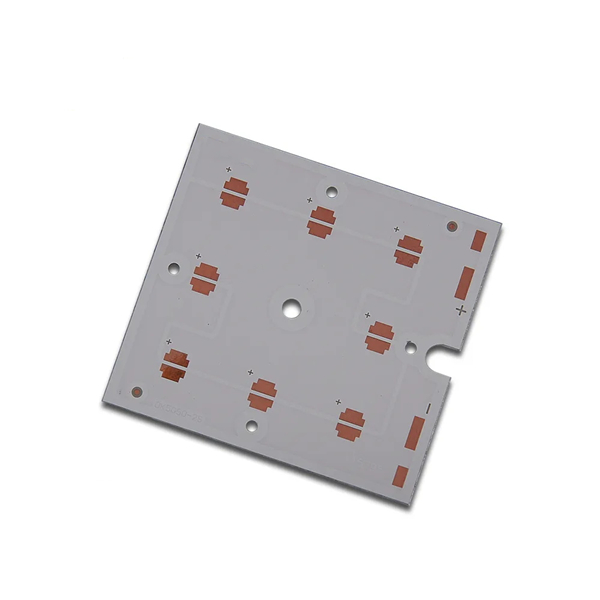

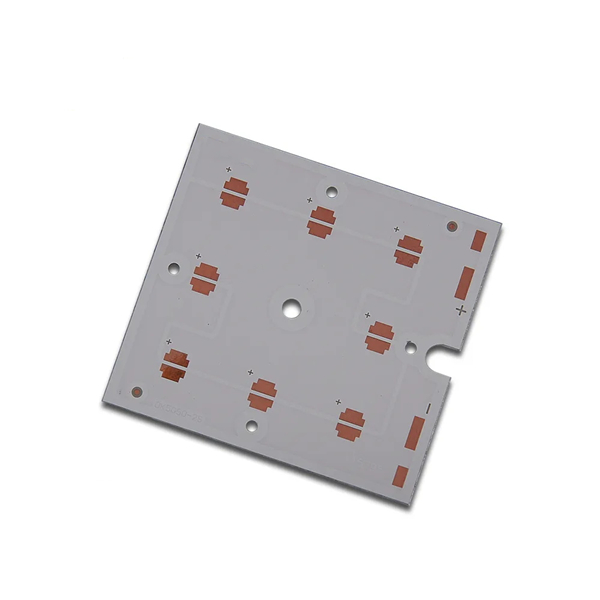

Oem Electronic Fabrication Aluminum Pcb Board

-

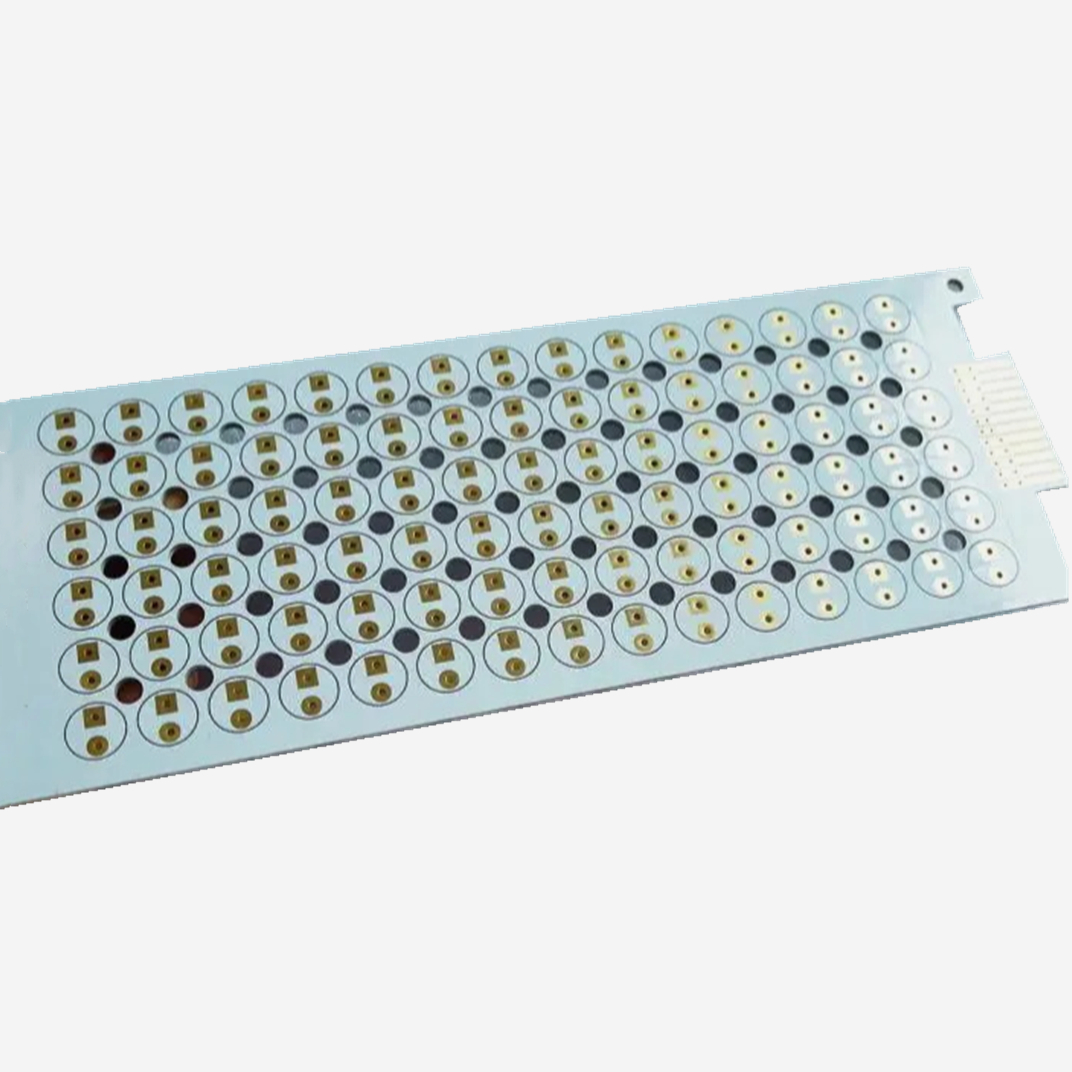

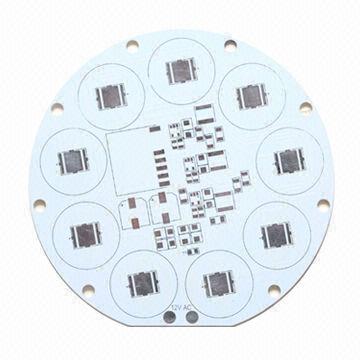

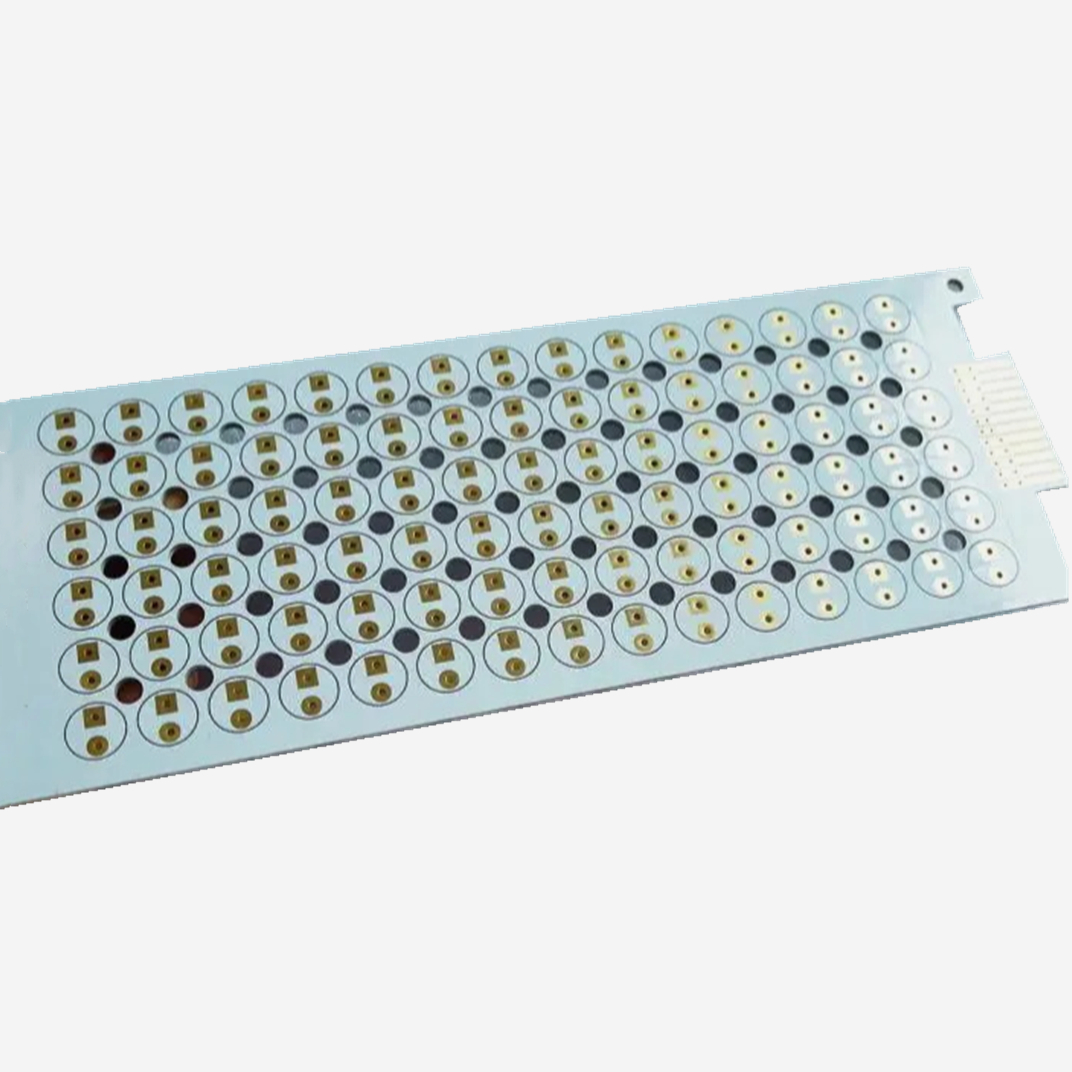

Electronic LED Aluminum PCB

-

LED Main Mother ALU PCB

-

Matel Core LED light Circuit Board

our advantages

-

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Quis ipsum suspendisse ultrices gravida. Risus commodo viverra maecenas accumsan lacus vel facilisis.Discover More

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Quis ipsum suspendisse ultrices gravida. Risus commodo viverra maecenas accumsan lacus vel facilisis.Discover More -

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Quis ipsum suspendisse ultrices gravida. Risus commodo viverra maecenas accumsan lacus vel facilisis.Discover More

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Quis ipsum suspendisse ultrices gravida. Risus commodo viverra maecenas accumsan lacus vel facilisis.Discover More -

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Quis ipsum suspendisse ultrices gravida. Risus commodo viverra maecenas accumsan lacus vel facilisis.Discover More

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Quis ipsum suspendisse ultrices gravida. Risus commodo viverra maecenas accumsan lacus vel facilisis.Discover More -

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Quis ipsum suspendisse ultrices gravida. Risus commodo viverra maecenas accumsan lacus vel facilisis.Discover More

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Quis ipsum suspendisse ultrices gravida. Risus commodo viverra maecenas accumsan lacus vel facilisis.Discover More